Hummer H1 (2002+). Manual - part 136

__________________________________________

Axles, Suspension, and Frame 9-5

®

05745159

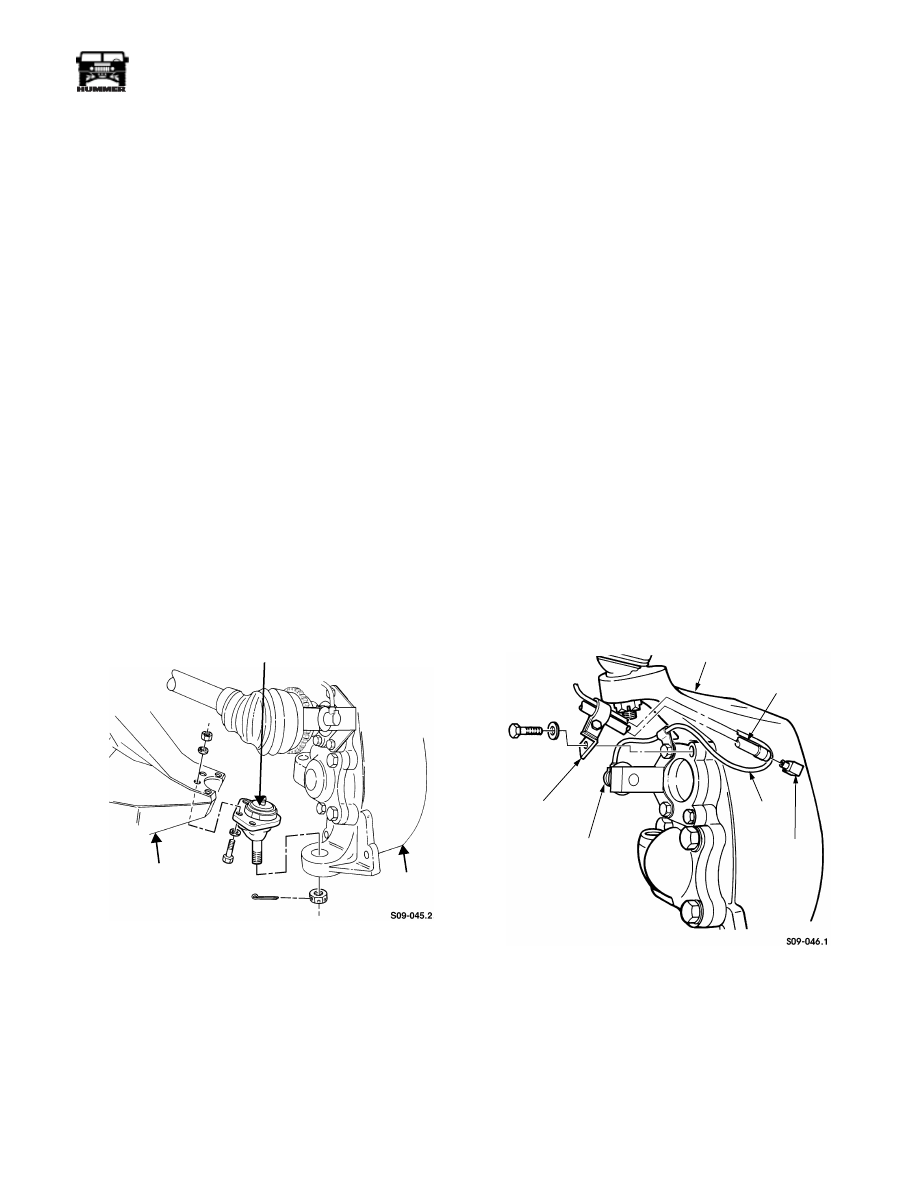

LOWER BALL JOINT REPLACEMENT

Removal

1.

Remove wheel.

2.

Raise and support lower control arm (Figure 9-8).

3.

Remove cotter pin and slotted nut from lower ball joint.

Discard cotter pin.

4.

Remove four locknuts, bolts, eight washers and lower ball

joint from lower control arm.

5.

Separate lower ball joint from geared hub using ball joint

remover J–24319-B or equivalent. Remove lower ball

joint.

Installation

1.

Install lower ball joint on lower control arm, ensuring low-

er ball joint is placed below lower control arm and secure

with four bolts, locknuts and eight washers. Tighten 7/16”

locknuts to 65 lb-ft (80 N•m) (Figure 9-8).

CAUTION:

Do not loosen slotted nut to install cotter pin. Do-

ing this may result in damage to equipment.

2.

Install ball joint on geared hub with slotted nut. Tighten

slotted nut to 73 lb-ft (99 N•m) and install cotter pin in

slotted nut.

3.

Lubricate lower ball joint.

4.

Install wheel (Section 6).

Figure 9-8: Lower Ball Joint Replacement

UPPER CONTROL ARM REPLACEMENT

NOTE:

The procedure for removing and installing the front

and rear upper control arms is basically the same. This proce-

dure covers the left front upper control arm.

Removal

1.

Remove wheel (Section 6).

2.

Remove bolt and washer securing vent line/speed sensor

lead bracket to geared hub (Figure 9-9).

3.

Disconnect vent line from fitting.

4.

Remove speed sensor from sensor mount bracket.

5.

Remove bolt, p-clamp, vent line and speed sensor lead

from upper control arm (Figure 9-10).

6.

Remove cotter pin and slotted nut from upper ball joint.

7.

Separate upper ball joint from geared hub using ball joint

remover.

8.

Remove four locknuts, bolts and eight washers securing

upper ball joint to upper control arm and remove upper

ball joint.

9.

Mark position of the eccentric reference holes on the

brackets for installation.

10. Remove two locknuts, washers, eccentrics, bolts, and

upper control arm from brackets and remove upper control

arm.

Figure 9-9: Vent Line Connection Replacement

LOWER BALL JOINT

LOWER

GEARED

CONTROL ARM

HUB

GEARED HUB

VENT LINE

BRACKET

FITTING

VENT LINE

SENSOR

LEAD

SPEED

SENSOR