Hummer H1 (2002+). Manual - part 90

___________________________________________

Transmission/Transfer Case 5-159

®

05745159

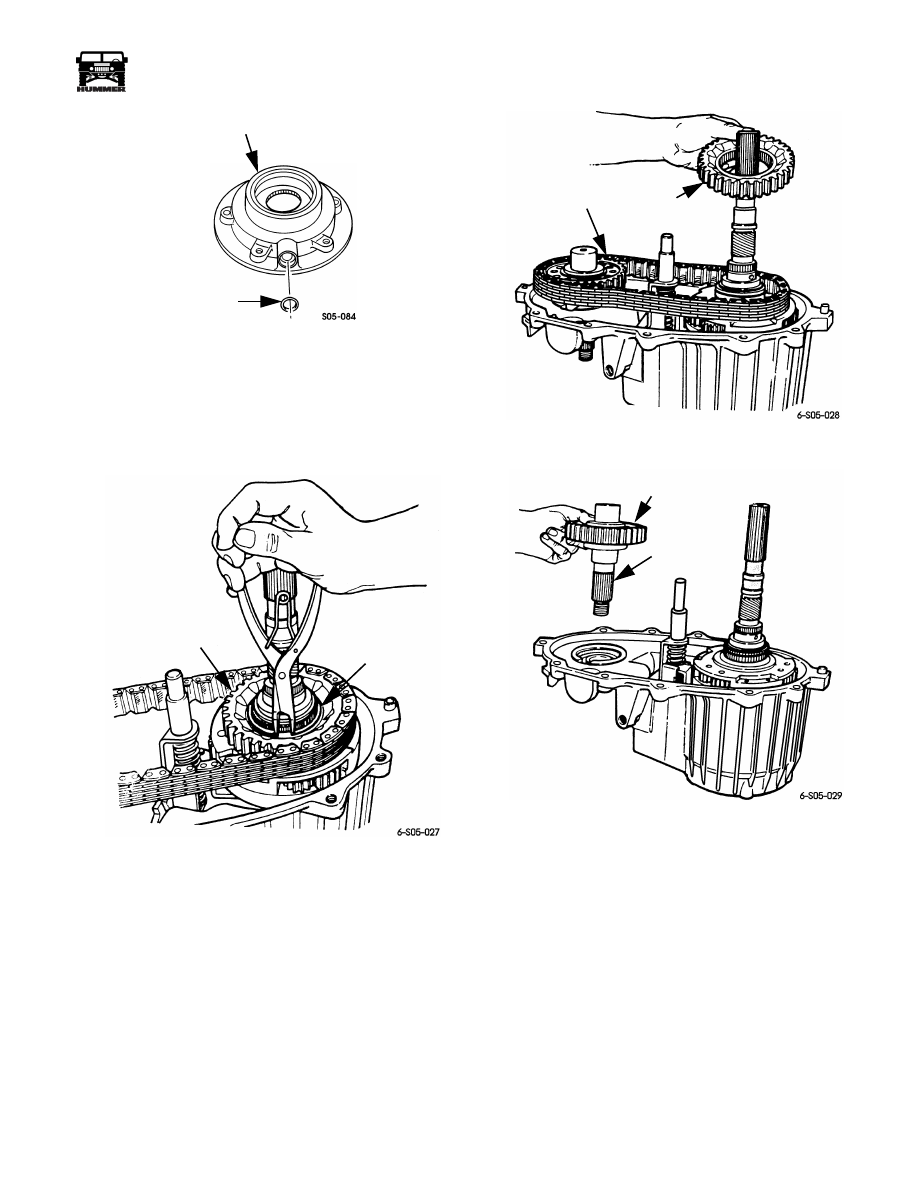

Figure 5-90: Oil Pump O-ring Location

11. Remove drive sprocket snap ring (Figure 5-91).

12. Remove drive sprocket (Figure 5-92).

13. Remove drive chain.

14. Remove front output shaft and driven sprocket as

assembly (Figure 5-93).

Figure 5-91: Drive Sprocket Snap Ring Removal/

Installation

Figure 5-92: Drive Sprocket Removal

Figure 5-93: Front Shaft and Driven Sprocket

Removal

15. Remove range lever nut, washer and lever from sector

shaft (Figure 5-94).

OIL PUMP

INLET PORT

O-RING

DRIVE

SPROCKET

SNAP RING

DRIVE

SPROCKET

DRIVE

SPROCKET

DRIVE

CHAIN

DRIVEN

SPROCKET

FRONT

OUTPUT

SHAFT