Hummer H1 (2002+). Manual - part 17

____________________________________________________________________

Engine 2-29

¨

05745159

REAR MAIN OIL SEAL REPLACEMENT

1.

Remove transmission and transfer case assembly.

2.

Remove flywheel.

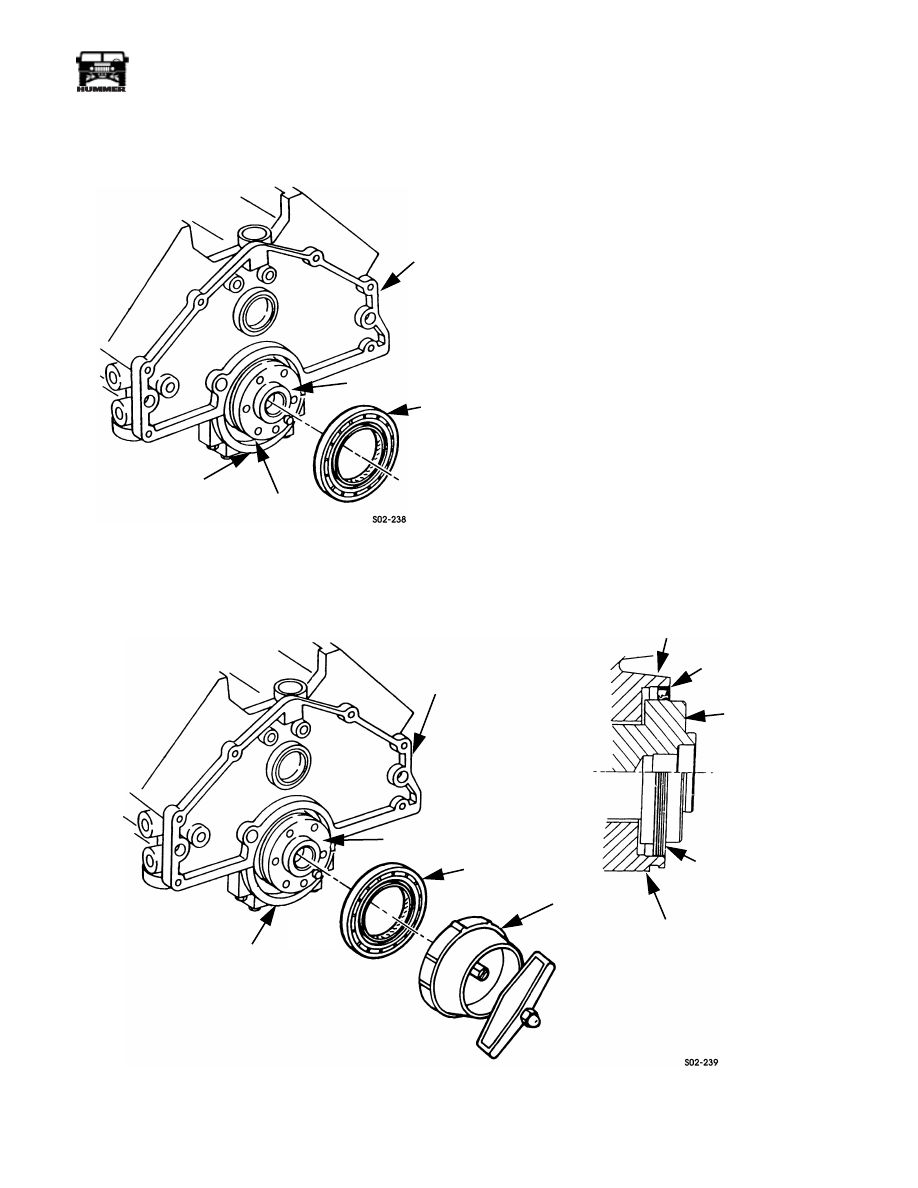

Figure 2-32: Rear Main Oil Seal Removal

CAUTION: Do not nick or scratch crankshaft seal surface

when removing old seal (Figure 2-32).

3.

Using small screwdriver or seal puller, remove old seal

from cylinder block and main bearing cap cavity.

4.

Clean old sealant or oil build-up from seal cavity. Check

for excess wear in crank.

5.

Lightly coat crankshaft and inner lip of seal with engine

oil. Lube oil and I.D. of seal.

6.

Position seal on crankshaft with seal lip toward block.

Ensure seal lip does not flip on installation.

7.

Position seal installer J

Ð

39084 on crankshaft, press seal into

cavity in block, then remove installer tool (Figure 2-33).

8.

Install flywheel on crankshaft. Tighten bolts to 66 lb-ft

(90 N¥m).

9.

Install transmission and transfer case assembly.

10. Run engine and check for leaks after assembly.

Figure 2-33: Rear Main Oil Seal Installation

BEARING CAP

CRANKSHAFT

SEAL

BLOCK

CAVITY

MAIN BEARING CAP

CRANKSHAFT

SEAL

BLOCK

BLOCK

SEAT SEAL FLUSH

CRANKSHAFT

SEAL

MAIN BEARING CAP

J39084

SEAL INSTALLER

WITH BLOCK

AND BEARING CAP