Great Wall V200. Service Manual - part 4

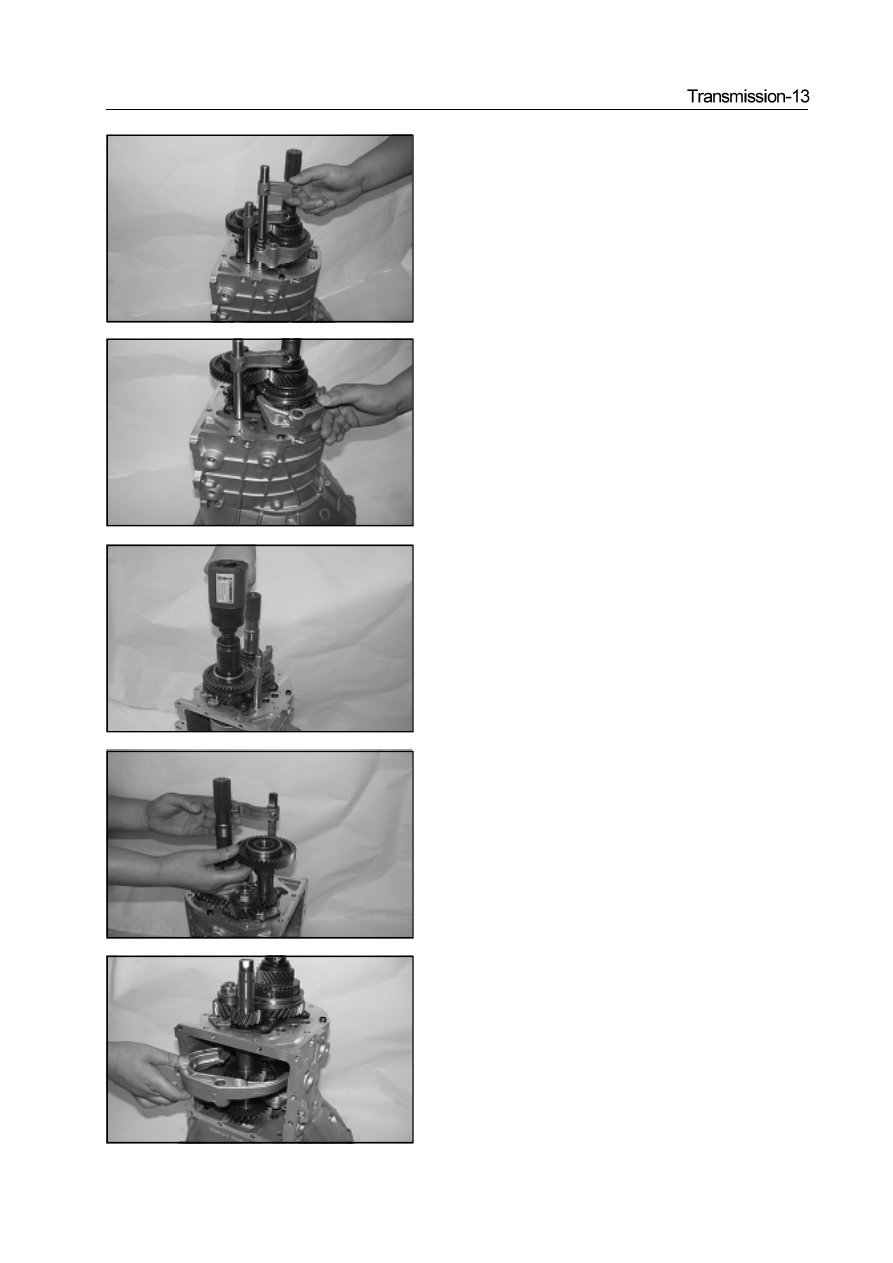

e. Remove the gear 3/4 declutch shift shaft assembly

f. Remove the reverse gear 5 shift fork

18. Remove the lock nut of intermediate shaft

Caution: When install the lock nut of intermediate shaft , the

tightening torque is 160-190N·m

19.Remove the Gear 1/2 declutch shift shaft assembly, intermediate

shaft rear ball bearing, 5th-Gear drive gear

20. Remove the Gear 1/2 shift fork