содержание .. 59 60 61 ..

Geely EC718, EC718RV, EC715, EC715RV. Manual part - 60

1

3

5

7

8

6

4

2

9

10

11

12

13

23

24

25

26

27

28

29

30

37

51

52

53

54

55

56

57

58

59

60

61

62

63

64

38

39

40

41

42

43

44

45

46

47

48

49

50

31

32

33

34

35

36

14

15

16

17

18

19

20

21

22

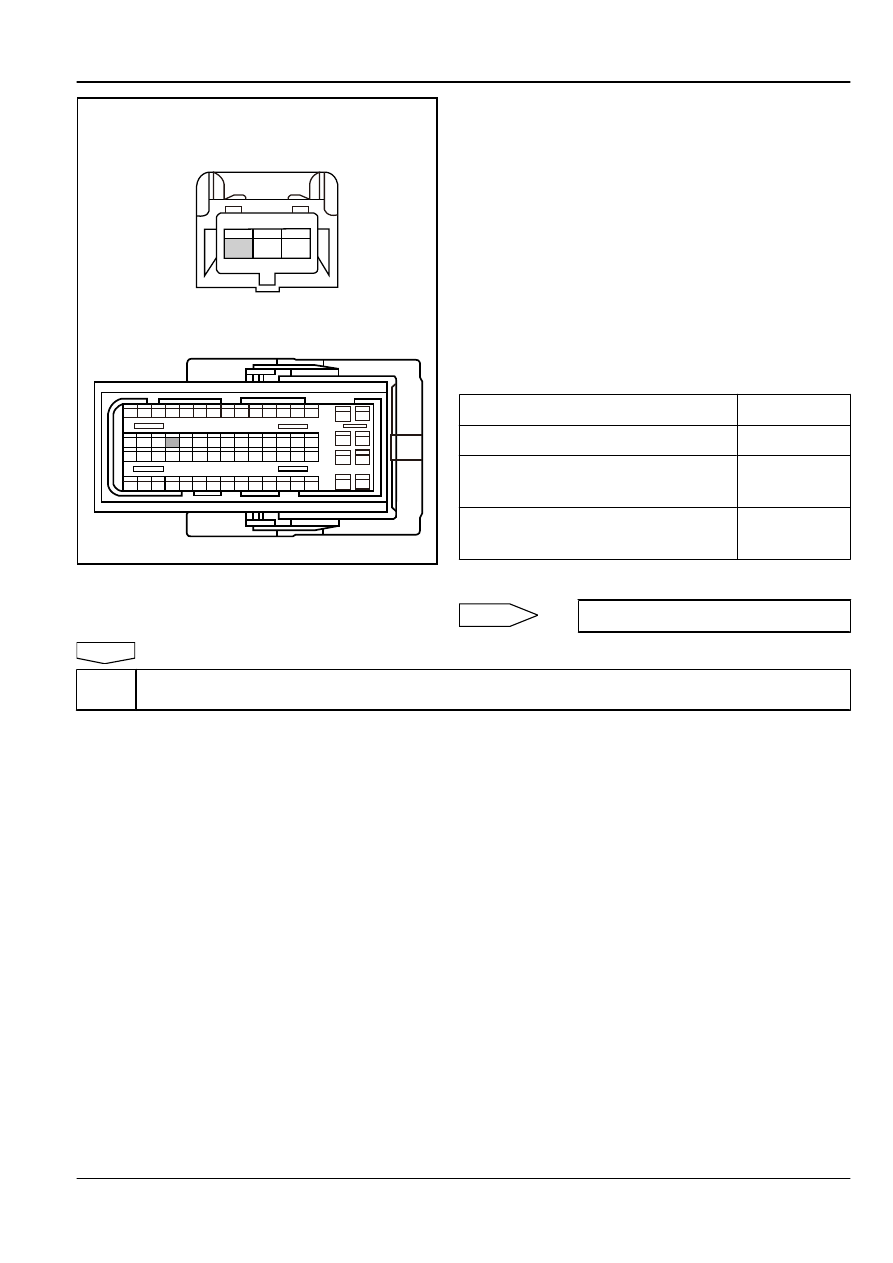

ECM Harness Connector EN01

Crankshaft Position Sensor Harness

Connector EN26

1

2

3

FE02-5080b

(a)

Turn the ignition switch to "OFF" position.

(b)

Disconnect the crankshaft position sensor wiring harness

connector EN26.

(c)

Disconnect ECM harness connector EN01.

(d)

Measure resistance between crankshaft position sensor

wiring harness connector EN26 terminal No.1 and ECM

harness connector EN01 terminal No.47. Check whether the

circuit is open.

(e)

Measure resistance between crankshaft position sensor

wiring harness connector EN26 terminal No.1 and a reliable

ground. Check whether the circuit is short to ground.

(f)

Measure resistance between crankshaft position sensor

wiring harness connector EN26 terminal No.1 and power

supply. Check whether the circuit is short to power supply.

Test Items

Standard Value

Resistance Between EN26 (1) and EN01 (47)

Less than 1 Ω

Resistance Between EN26 (1) and a Reliable

Ground

10 kΩ or higher

Voltage Between EN26 (1) and a Reliable

Ground

0 V

Are the values specified values?

No

Repair the faulty part. Go to step 10

Yes

Step 6

Check sensor terminal No.2 circuit.

Engine

Control System JL4G18-D

2-155