Daewoo Musso. Manual - part 33

1B1-68 M162 ENGINE MECHANICAL

Tools Required

111 589 01 59 00

Supporting Bar

111 589 18 61 00

Lever Pusher

111 589 25 63 00

Thrust Piece

116 589 06 63 00

Magnetic Finger

Removal & Installation Procedure

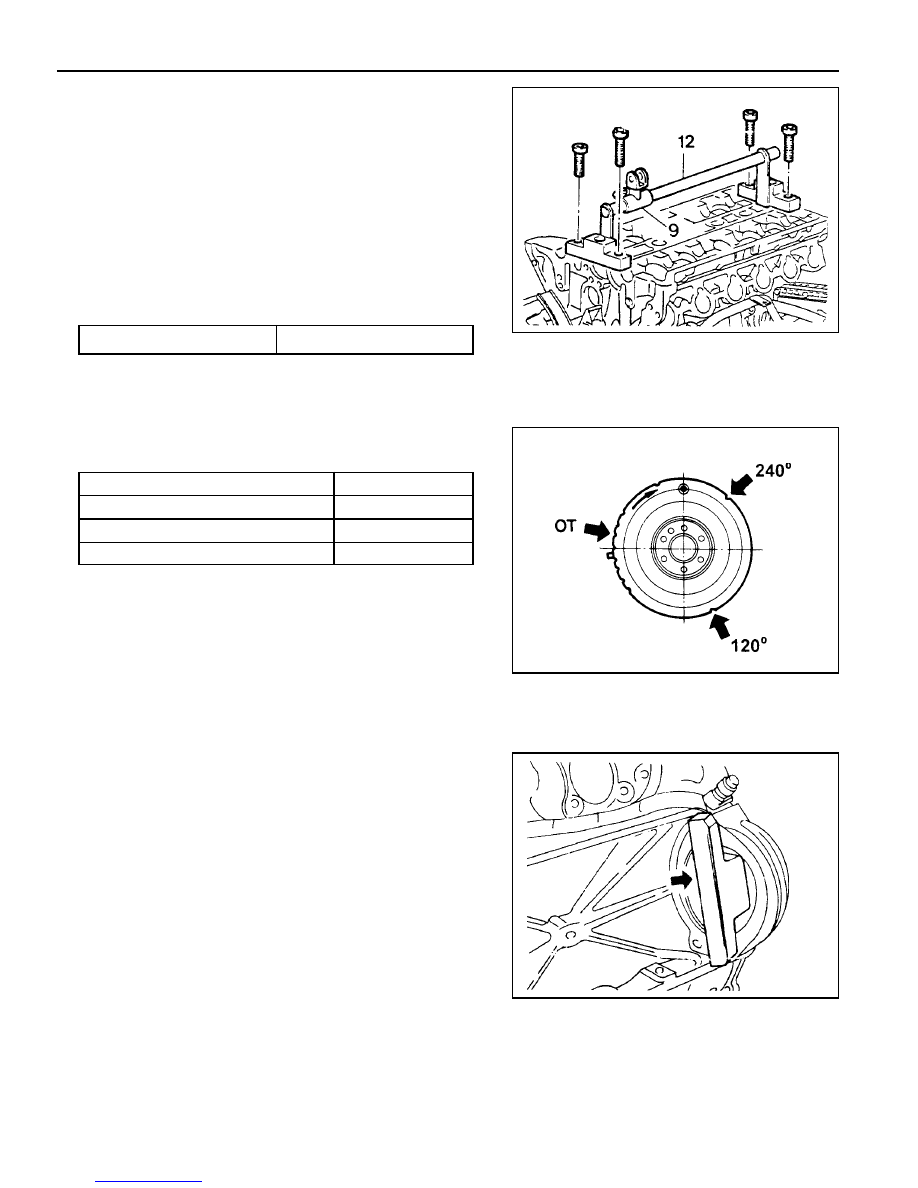

1. Place the supporting bar (12) and the slide (9) at the

camshaft bearing cap (Nos 1 & 7/8&14) and tighten them

with the bearing cap bolt.

Installation Notice

2. Turn the crankshaft to position the each cylinder piston at

TDC.

5. Install the engine lock to the ring gear to prevent the

crankshaft from rotating.

6. Blow up with compressed air.

Notice

l

Remove the valve spring only at TDC.

l

Always rotate the crankshaft by holding the chain to

prevent from timing chain damage and tangling, and for

smooth rotation.

3. Remove the valve tappet (1) using the magnetic finger.

4. Install the leakage tester connecting hose to the spark plug

hole.

Supporting Bar 111 589 01 59 00

Tightening Torque

22.5 - 27.5 Nm

Mark on The Vibration Damper

OT

120°

240°

Cylinder

1, 6

2, 5

3, 4