Daewoo Nubira. Manual - part 216

8B – 10

I

SUPPLEMENTAL INFLATABLE RESTRAINTS (SIR)

DAEWOO V–121 BL4

Sensing and Diagnostic Module (SDM) Integrity Check

CAUTION : The SDM can maintain sufficient voltage

to deploy the airbags for 10 minutes after the ignition

is OFF and the fuse has been removed. If the airbags

are not disconnected, service cannot begin until 10

minutes have passed after disconnecting power to

the SDM.

CAUTION : During service procedures, be very care-

ful when handling the SDM. Never strike or jar the

SDM. Never power the SIR system when the SDM is

not rigidly attached to the vehicle. All SDM mounting

bolts must be carefully tightened, and the SDM arrow

must be pointing toward the front of the vehicle to en-

sure proper operation of the SIR system. The SDM

could be activated if it is powered when it is not rigidly

attached to the vehicle, resulting in unexpected de-

ployment and possible injury.

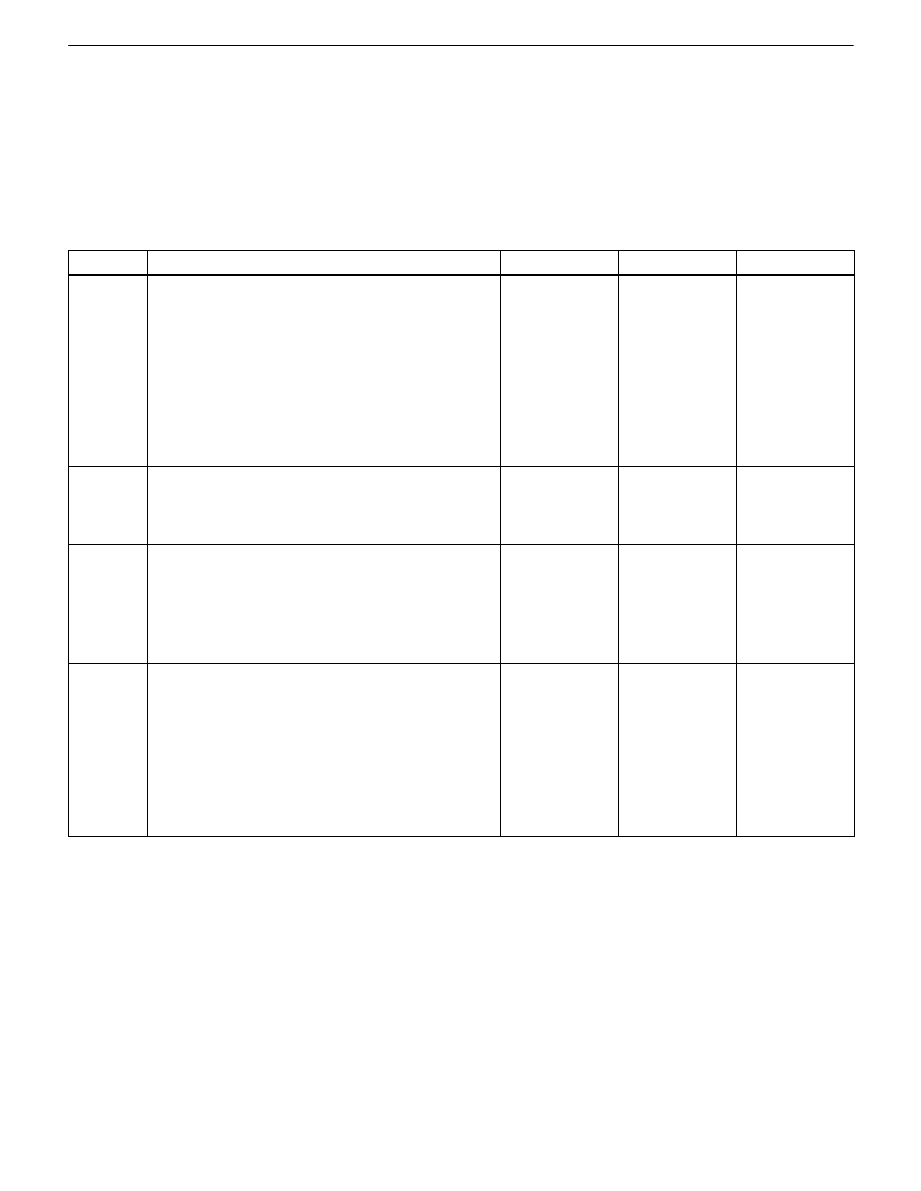

Step

Action

Value(s)

Yes

No

1

1. Turn the ignition to LOCK and remove the key.

2. Connect all supplemental inflatable restraint

(SIR) system components, and ensure that all

components are properly mounted.

3. Ensure that the ignition switch has been OFF

for at least 30 seconds.

4. Observe the AIRBAG indicator as the ignition

is turned ON.

Does the indicator lamp flash seven times and then

turn off?

Clear the SIR

system DTCs

and go to

”Diagnostic

System Check”

Go to Step 2

2

Using a scan tool, request the DTC display.

Is the same DTC displayed that was previously oc-

curring when the SIR Diagnostic System Check was

previously performed?

Go to Step 3

Go to the table

for the DTC in-

dicated

3

1. Clear the SIR DTCs.

2. Turn the ignition OFF for at least 30 seconds.

3. Observe the AIRBAG indicator as the ignition

is turned ON.

Does the AIRBAG indicator flash seven times and

then turn off?

System OK

Go to Step 4

4

1. Turn the ignition to LOCK and remove the key.

2. Disconnect the passenger airbag and the yel-

low clock spring connector on the steering col-

umn.

3. Replace the SDM. The arrow must be pointing

toward the front of the vehicle.

4. Connect all SIR system components, and en-

sure that all components are properly mounted.

Is the repair complete?

Clear the SIR

system DTCs

and go to

”Diagnostic

System Check”