Daewoo Nubira. Manual - part 160

Description

Page

Fuel Level Sensor Procedures

6 of 7

August, 2001

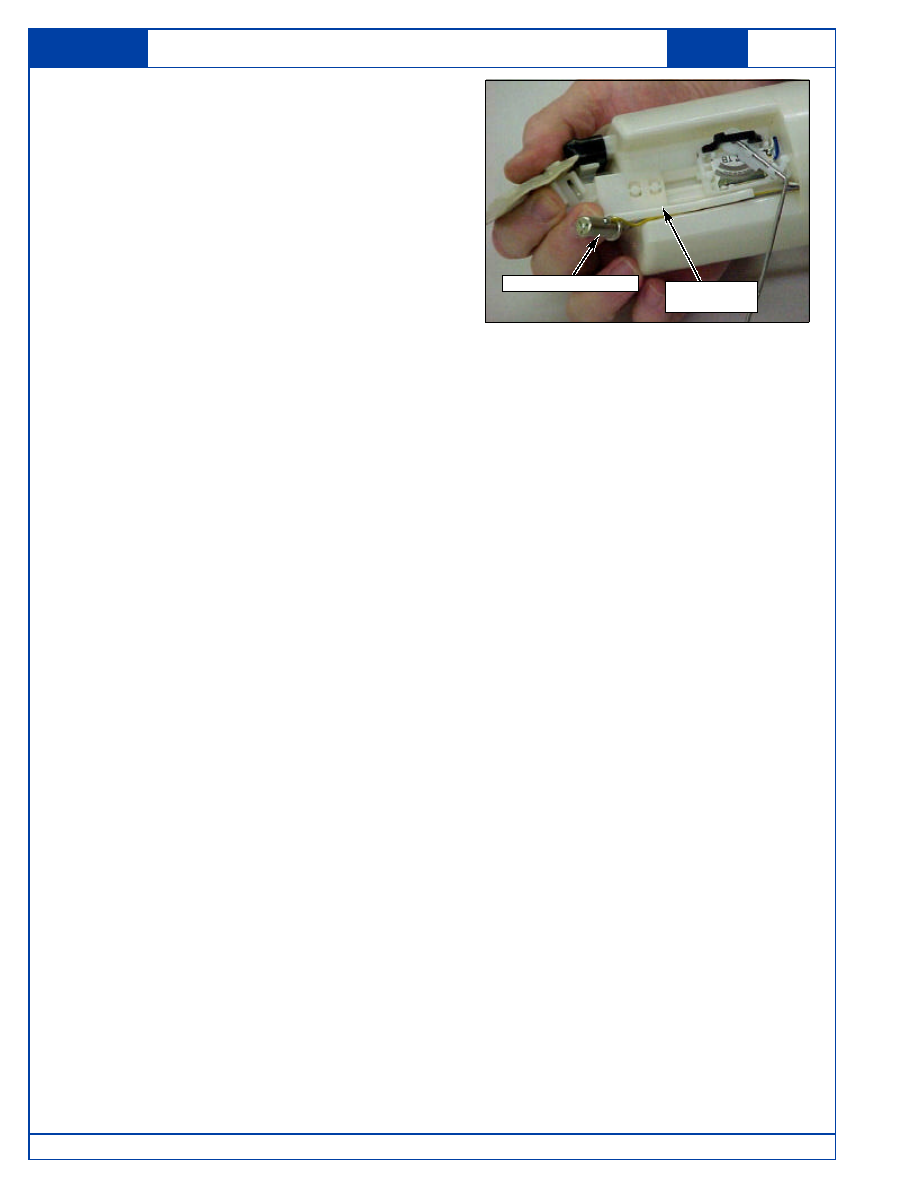

16. Guide the Low Fuel Level Sensor Bracket

onto the retaining rail on the Fuel Pump

Module Body. An audible "click" will be heard

as it locks into it’s proper position.

17. Reinsert the Low Fuel Level Sensor onto its

bracket.

18. Test the new Fuel Level Sensor by using the

procedure described in steps 18 through 23 of

the Fuel Level Sensor Diagnostic Procedure

before reinstalling the Fuel Pump Module into

the Fuel Tank.

Low Fuel Level

Sensor Bracket

Low Fuel Level Sensor

19. Using a new O-ring, carefully reinstall the Fuel Pump Module into the Fuel Tank. Take care

not to damage the O-ring or bend the Fuel Level Sensor Float Arm.

CAUTION: Removing components from a sealed fuel system exposes fuel vapors to

outside oxygen and possible sources of combustion. A fuel system should

only be opened in a properly ventilated area. Special caution should be

used when removing components from a fuel tank or fuel system. Removal

of such components should only be done away from open flame (torches,

lit cigarettes, heater pilots or other flames however minor) or sparks

(mechanical, electrical or otherwise) that could cause fuel vapors to ignite.

20. Using a suitable hammer and brass drift, reinstall the Fuel Pump Module Retaining Ring by

rotating it clockwise until it reaches it's stops.

21. Reconnect the Wiring Harness Connector to the Mounting Flange Connector on the Fuel

Pump Module.

22. Reinstall the Fuel Pump Outlet Hose by pushing it firmly into place. An audible “click” will

be heard when the hose is properly connected.

23. Reinstall the Fuel Tank Return Hose by pushing it firmly into place. An audible “click” will

be heard when the hose is properly connected.

24. Reinstall the Fuel Pump Relay into the Engine Compartment Fuel/Relay Box.

25. Turn the Ignition Switch to the “ON” position and verify that the Fuel Pump operates for

approximately 3 seconds by listening for pump motor operation, then check the Fuel

Pump Module for leaks.

26. Road test the vehicle, then recheck the area around the Fuel Pump Module for fuel leaks.

27. Reinstall the Fuel Pump Module Access Cover by pressing it into place.

28. Reinstall the rear seat cushion.

Lanos ONLY - Reinstall the Rear Seat Cushion retaining bolt removed previously.