Daewoo Nubira. Manual - part 121

1F – 368

I

ENGINE CONTROLS

DAEWOO V–121 BL4

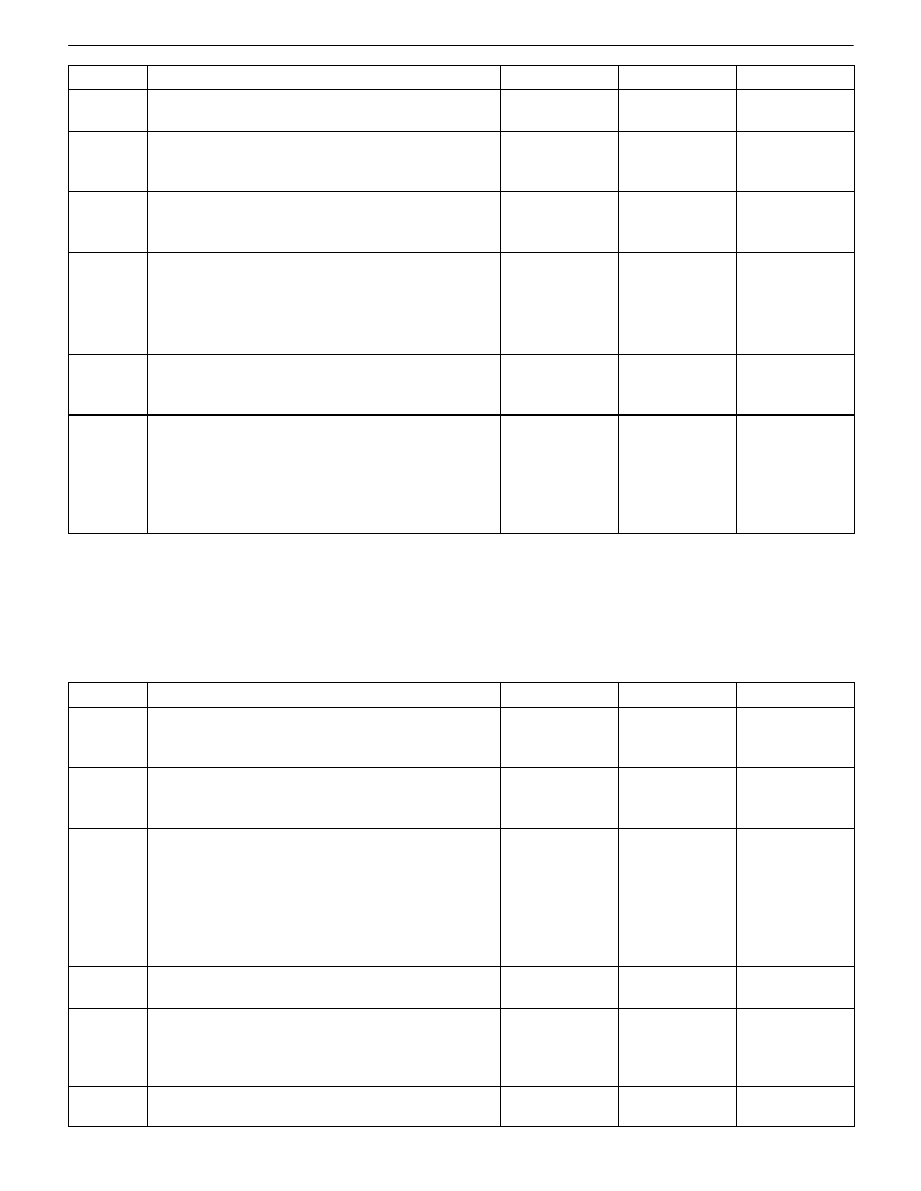

Step

No

Yes

Value(s)

Action

11

Replace any restricted or leaking fuel injectors.

Is the repair complete?

System OK

12

Check the fuel system pressure after a cold start or

during moderate or full throttle acceleration.

Is the fuel pressure within specifications?

41–47 psi

(284–325 kPa)

Go toStep 14

Go toStep 13

13

Repair the restriction in the fuel system or replace

the faulty fuel pump.

Is the repair complete?

System OK

14

1. Check for faulty ignition wires.

2. Inspect for fouled spark plugs.

3. Check the ignition system output on each cylin-

der with a spark tester.

Is the problem found?

Go toStep 15

Go toStep 16

15

Repair or replace any ignition components as need-

ed.

Is the repair complete?

System OK

16

1. Check the generator output voltage.

2. Repair or replace the generator if the generator

output is less than the value specified.

3. Check the Exhaust Gas Recirculation (EGR)

valve operation.

Are all checks and needed repairs complete?

12–16 v

System OK

CUTS OUT, MISSES

This Involves a steady pulsation or jerking that

follows engine speed, usually more pronounced as

engine load increases. The exhaust has a steady

spitting sound at idle or low speed.

Step

Action

Value(s)

Yes

No

1

Were the Important Preliminary Checks performed?

Go toStep 2

Go to”Impor-

tant Preliminary

Checks”

2

Check the ignition system output voltage for all of the

cylinders using a spark tester.

Is spark present on all of the cylinders?

Go toStep 3

Go to”Ignition

System Check”

3

1. Inspect the spark plugs for excessive wear,

insulation cracks, improper gap, or heavy de-

posits.

2. Check the resistance of the ignition wires. Re-

place any ignition wires that have a resistance

greater than the value specified.

Is the problem found?

30,000

Ω

Go toStep 4

Go toStep 5

4

Repair or replace any components as needed.

Is the repair complete?

System OK

5

With the engine running, spray the ignition wires with

a fine water mist to check for arcing and shorting to

ground.

Is the problem found?

Go toStep 6

Go toStep 7

6

Replace the ignition wires.

Is the repair complete?

System OK