DAF CF65, CF75, CF85 Series . Manual - part 962

©

200423

3-5

Inspection and adjustment

STEERING BOX

ΧΦ65/75/85 series

7

3

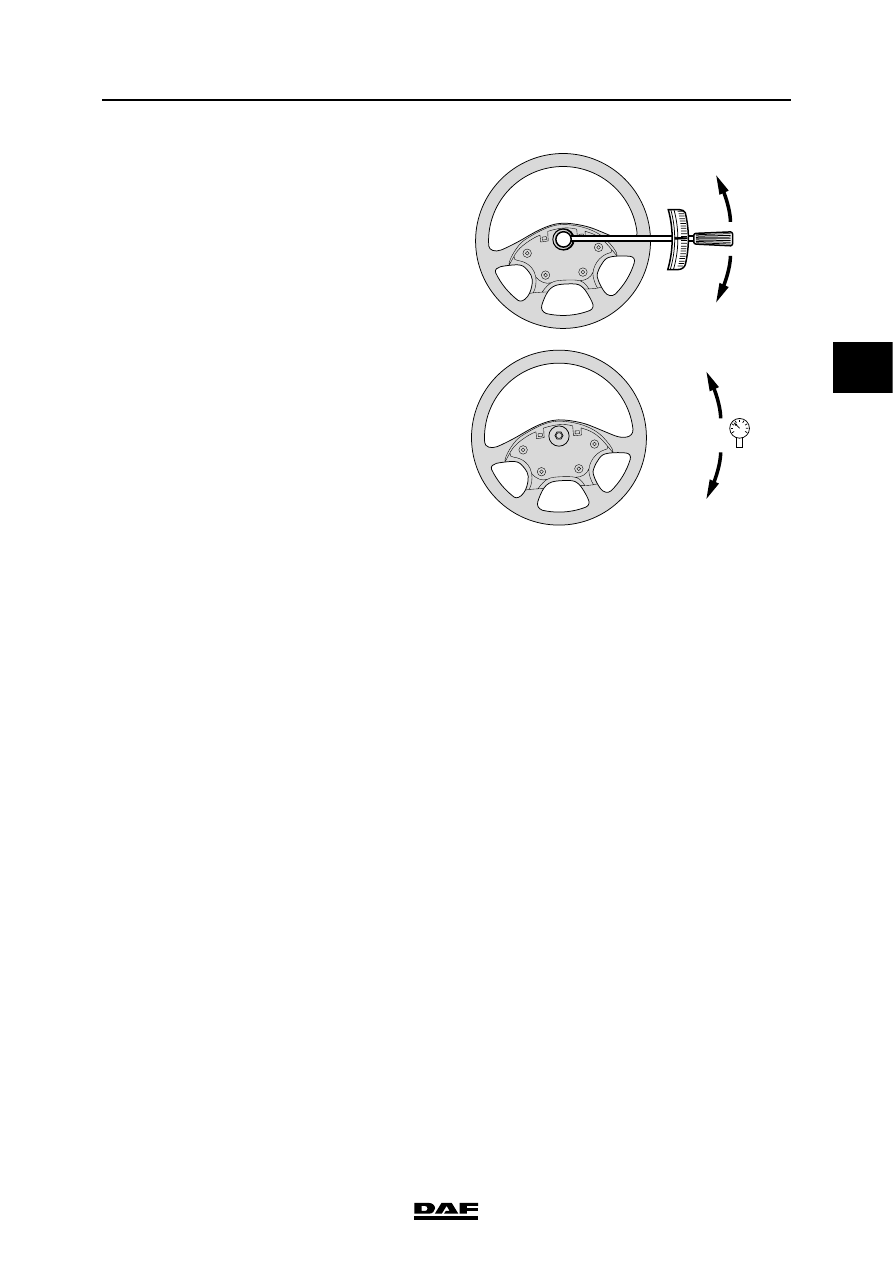

16. Turn the steering wheel fully left (RHD fully

right) until the end stop is reached. Fit a

torque wrench to the steering wheel nut and

pull on the torque wrench with a tightening

torque of 35 Nm. The maximum reading on

the pressure gauge should be 80 bar.

This will correctly re-adjust the wheel

deflection limiting valve, which has its end

stop at the steering box cover.

17. Run the engine at idling speed and turn the

steering wheel fully right (RHD fully left) until

the end stop is reached. The pressure

should not exceed approx. 100 bar; this

pressure should not be continued for more

than 5 seconds.

18. While the steering wheel is at its end stop,

loosen the lock nut one turn and screw in the

adjusting bolt, while securing the lock nut at

the same time.

Screw in the adjusting bolt, until the pressure

is reduced to a maximum of 80 bar. This will

correctly re-adjust the wheel deflection

limiting valve, which has its end stop against

the adjusting bolt.

19. Set the engine speed to 1200 - 1400 rpm.

The final limiting pressure should not exceed

80 bar.

Screw the adjusting bolt in further if the

pressure is too high.

Note:

Do not screw in the adjusting bolt further than

is strictly required, as the other wheel

deflection limiting valve could lose its

previous setting in this way, in which case

the adjusting procedure must be repeated

from the start.

There is also the chance that the wheel

deflection limiting valve will open too early,

thus reducing the pressure too fast so that

maximum wheel deflection is not reached.

20. Tighten the lock nut to the specified

tightening torque. See 'Technical data'.

21. Turn the steering wheel fully left (RHD fully

right) until the end stop is reached. Set the

engine speed to 1200 - 1400 rpm and check

the final limiting pressure.

LHD

RHD

35Nm

S7 00 562

RHD

LHD

max.

100 bar

S7 00 563