DAF LF45, LF55 Series. Manual - part 453

©

200436

2-33

Description of components

OPERATION OF BRAKE COMPONENTS

ΛΦ45/55 series

6

3

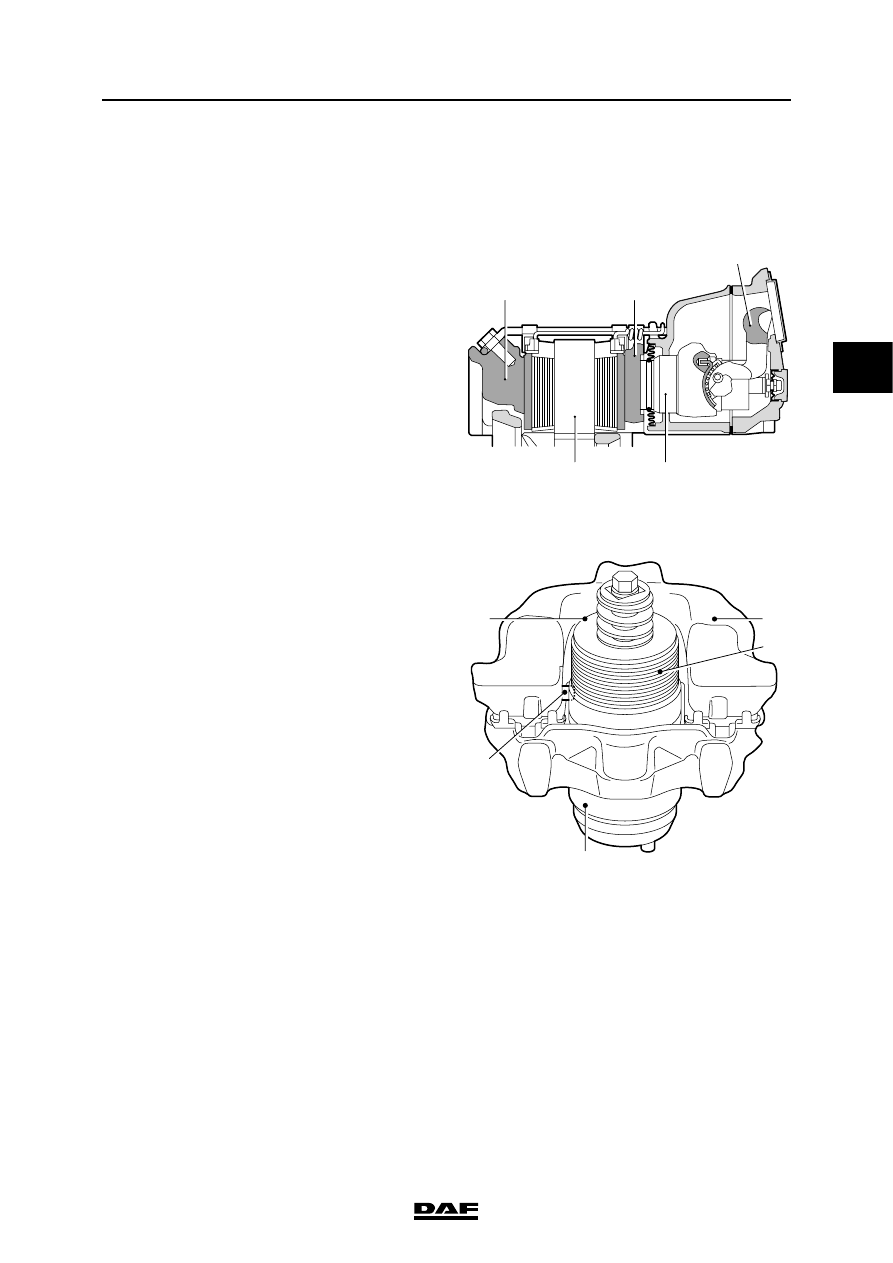

2.18 DISC BRAKE CONSTRUCTION, WABCO MODEL

PAN 17 and PAN 19-1+ versions

Operation

Brakes

This disc brake operates using a pneumatic

brake cylinder or spring brake cylinder.

If the brake is applied, the brake cylinder push

rod presses against the eccentrically mounted

lever (1).

Via brake cylinder 2 and pressure plate 3, the

brake pad is pressed against the inside of the

brake disc (4).

Due to the reaction force at the eccentric, the

floating brake calliper (5) will also press the

opposite brake pad with the same force.

Adjusting

If the eccentrically mounted lever (6) is operated

by the push rod of the brake cylinder, the pin (7)

on the lever will rotate the adjuster (8) and the

pressure cylinder (9) in the outgoing stroke until

the play has been eliminated.

If the brake is no longer being operated, the

lever (6) will turn the adjuster (8) back in the

opposite direction. The spring (10) in the adjuster

will ensure that the pressure cylinder will hardly

rotate. The result is that a small total play of about

0.5 mm will remain between the brake pads and

brake disc.

Brake pad wear wires

Brake pad wear wires are fitted to the brake pads.

These wires are cut through when the brake

lining has been worn down to the minimum

thickness.

This is the signal for the VIC system to activate

the "brake pad wear" warning symbol on DIP-4.

R600573

R600574

1

3

5

4

2

R600579

9

7

8

6

10