DAF LF45, LF55 Series. Manual - part 225

©

200508

4-1

Automatic gearbox

DIAGNOSTICS

ΛΦ45/55 series

3

1

4. AUTOMATIC GEARBOX

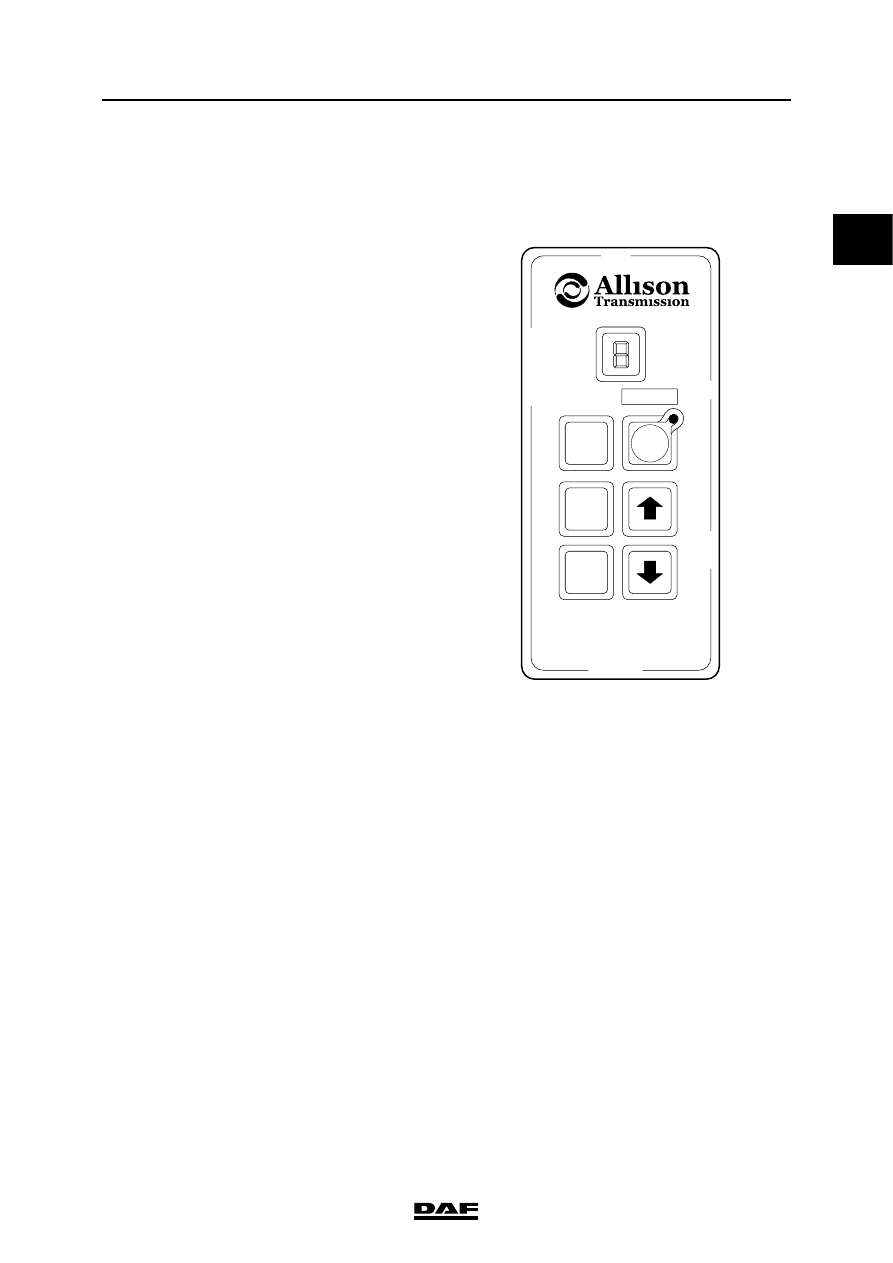

4.1 READING/DELETING ALLISON MD 3060 FAULT CODES

Fault code read function

To enter the fault code reading mode, briefly

press the two arrow keys twice simultaneously.

"D-1" appears on the display, followed by "-".

This means that at that point there are no faults

(active faults) in the system. It also means that no

faults have been registered that were earlier

temporarily present and have now been cleared

(inactive faults). The fault code reading function

can be left by pressing "D", "N", or "R" or the

arrow keys.

If the red lamp lights up while reading a fault

code, this means that there is an active fault in the

gearbox.

No message during reading means that the fault

is inactive.

The ECU can save five active/inactive fault codes

in its memory and show them on the display.

Fault codes consist of two sets of two digits (main

codes and sub-codes). To read the codes

consecutively, the "MODE" button must be

pressed each time.

The letters and digits appear one at a time on the

display.

The hyphen after D4 means that there are no

further faults and that it is therefore not necessary

to look at level D5.

As the ECU can only contain the five most

important codes, the five most important codes

will be seen on D1 to D5. Only when one of the

faults has been remedied will the ECU be in a

position to show a less important fault.

R

D

MODE

N

V300392

Example:

D1

25 - 22

D2

21 - 12

D3

24 - 12

D4

-