Chery A15. Manual - part 79

Maintenance of brake caliper assy.

* Check the crack and deformation of the brake caliper, and correct or replace it as

appropriate.

* Check the breakage and crack of the dust boot of piston, and replace the boot, if any.

* Check the aging, crack and other defectives of the sealing ring of piston, and replace the

ring, if any.

* Check the oil leakage, motion blocked, unsmooth return of the piston, and repair it, if

any. Check the damage, corrosion and other defectives of the piston and cylinder wall, and

replace the brake caliper assy., if any.

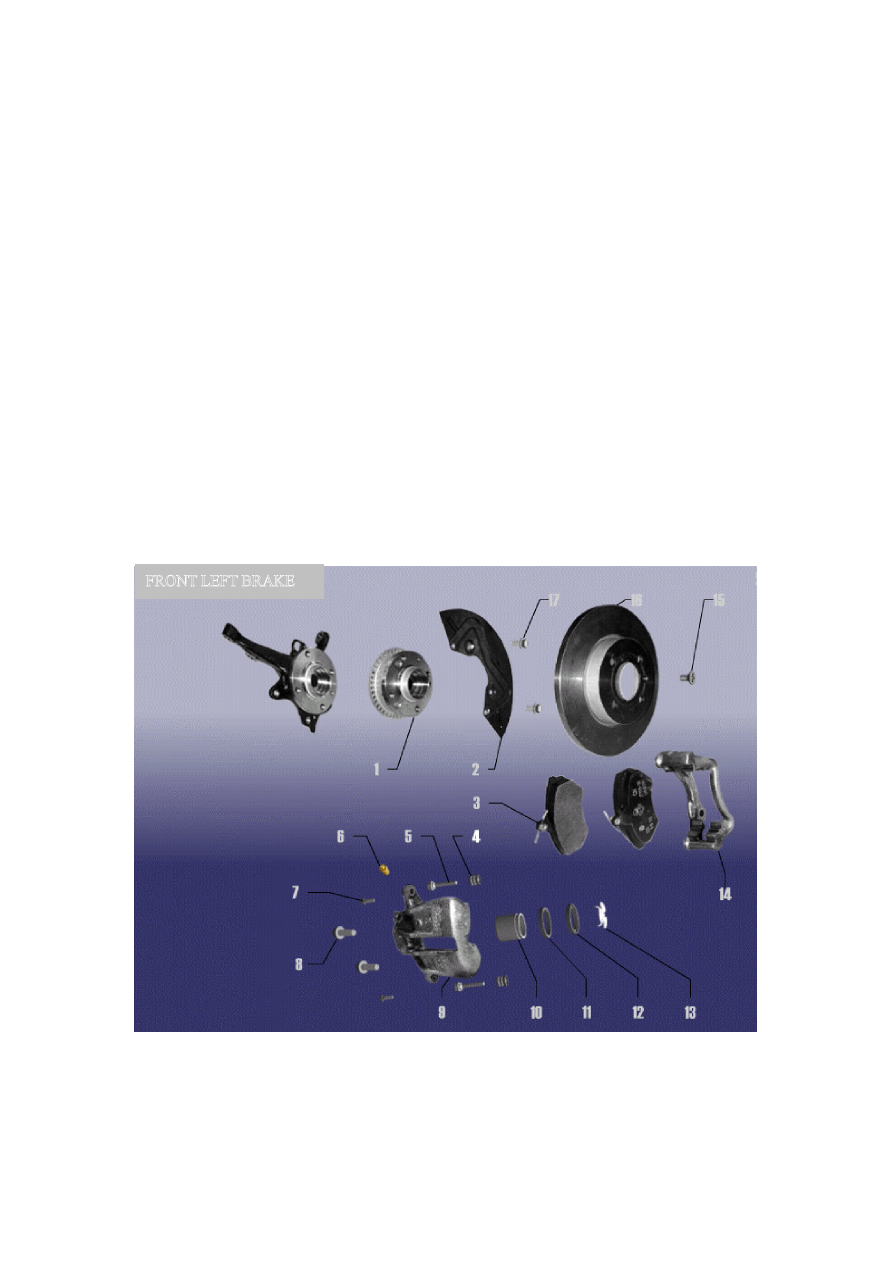

EXPLOSION CHART AND STRUCTURAL CHARACTERISTICS OF FRONT

WHEEL DISC BRAKE

The front wheel disc brake adopts the single-cylinder floating caliper structure in where the

brake caliper body may slide in the axial direction relatively to the brake disc, the structure

of which is shown in the figure below.

Front Wheel Disc Brake

P-9