Chery A15. Manual - part 63

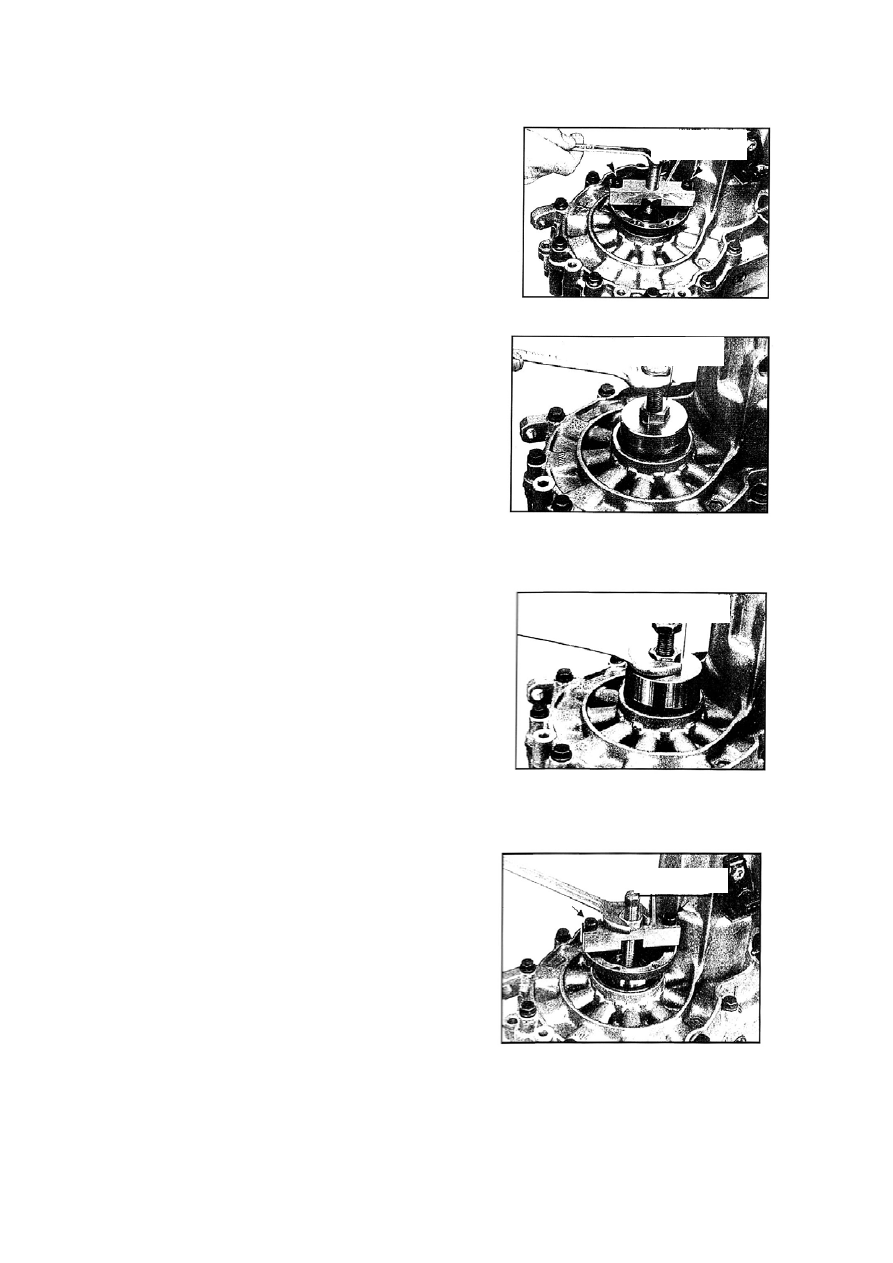

——See the picture, fix the special tool on flange

by M8 bolt, rotate the shaft of special tool by

wrench to disassemble the output flange.

Take off spring seat and compression spring.

——Fasten the special tool on oil seal, rotate the

special tool threaded shaft by wrench until

screw off the oil seal.

Assembly:

——Use the right size oil seal and lubricate its lip.

Put it to its right position by special tool and

rotate the screw of the special tool make oil

seal to its true position.

——For the assembly of output flange, you can

use press or special tool press it into its

position, see the picture.

——Assemble dish washer and check if it is at its

right position

——Assemble snap ring and make sure it is inside

of snap ring groove.

——Assemble a new flange cover.

——Connect drive shaft and output flange

together, if it is necessary put lubricant to the

stipulated position.

Special Tool

Special Tool

Special Tool

Special Tool

J-43