Chery A15. Manual - part 24

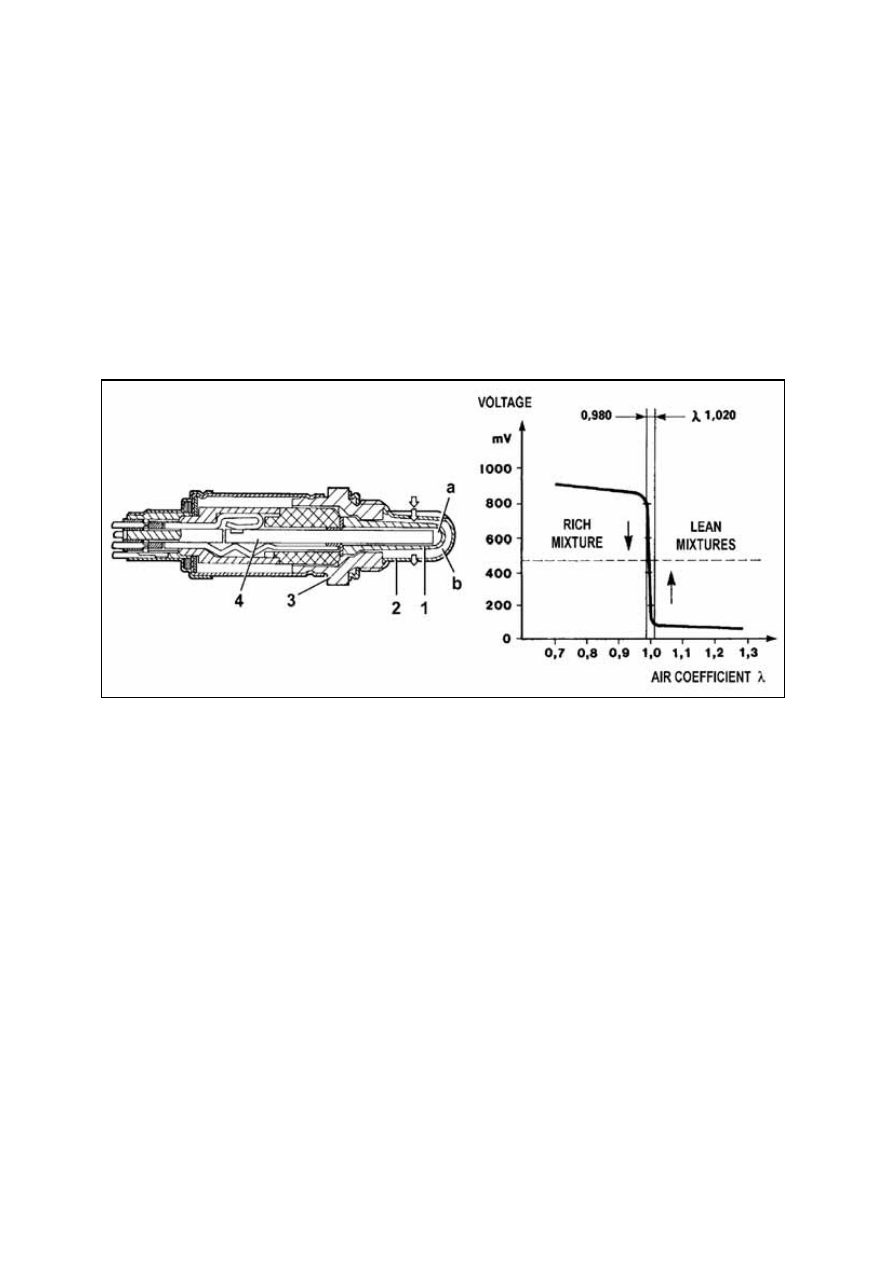

the mixture concentration value in time and change mixture thicker or thinner to make it

always be close to chemical reaction equivalence ratio. The voltage range of which is

0.980~1.020V.

To reach working temperature rapidly (~300°C), a resistor (4) installed in the sensor can

shorten the starting electric time of the porcelain. It means sensor can be installed in cold area

of exhaust hose. If mixed gas concentration is thinner than chemical reaction equivalence ratio

when working in full speed, ECU will give signal to the oxygen sensor to add mixture thicker

(half-closed loop).

Oxygen sensor doesn’t work under cut-off and full load condition, which is called open loop.

Recovery:

If fault occurs in sensor or resistor, all information will be ignored and the whole system will

work as an opened loop system.

Oxygen sensor test procedure:

If diagnosis tester displays signal as “lambda sensor error “, please check:

——

If there is air leakage in every manifold, pipes, brake booster, exhaust gas and fuel-vapor

re-cycle system.

——

Spark wear and efficiency of high voltage wire insulator.

——

If timing and positioning of TDC (top dead center)/rotate speed sensor is right or not.

——

Tappet clearance and engine compression ratio.

——

If supplied oil pressure is right or not.

F-10