Chery A15. Manual - part 17

OIL PUMP AND FRONT OIL SEAL

Disassembly:

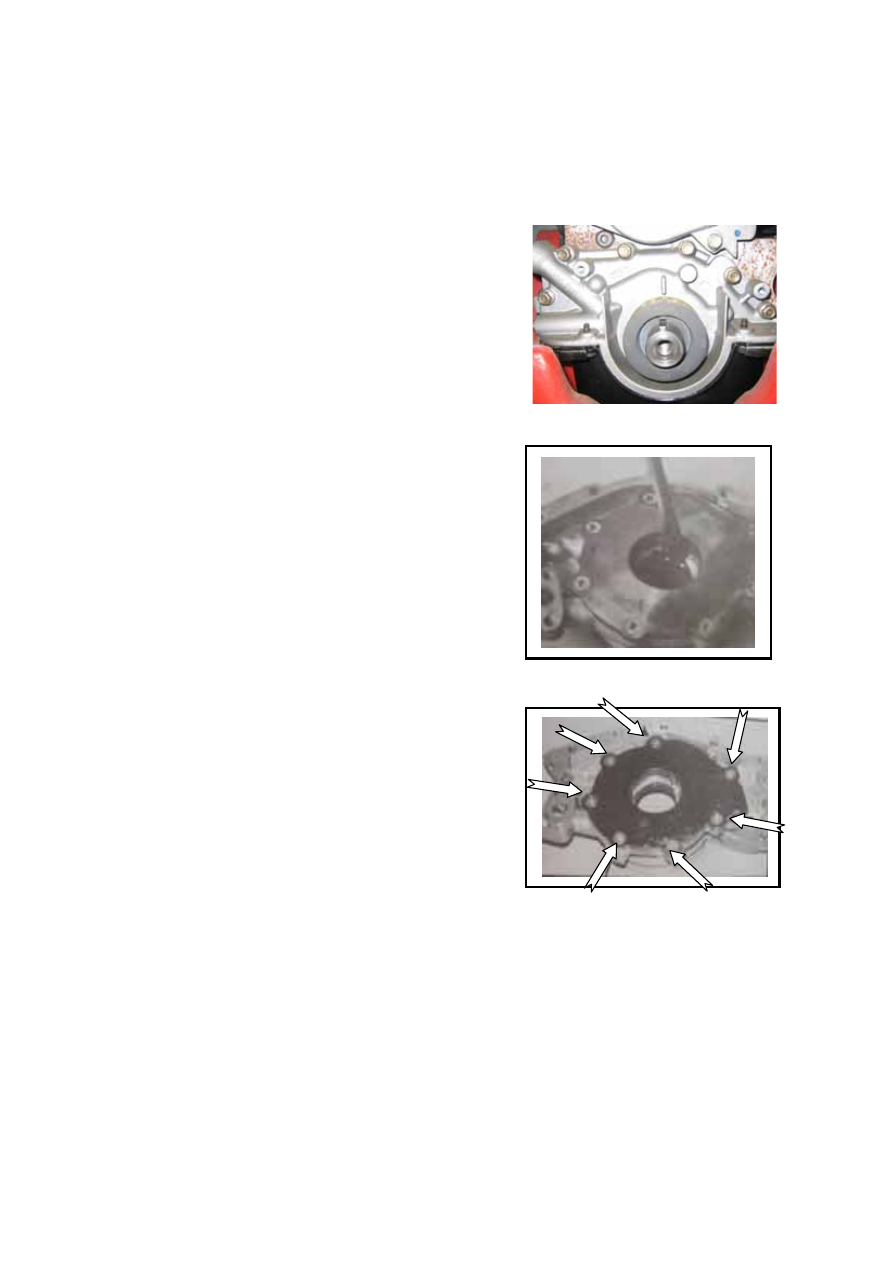

——To unscrew and take out six M6X30 hexagon

flange bolts.

——To take out oil pump and front oil seal assembly.

——To use a screwdriver or chisel to take out the

crankshaft front oil seal and pay attention not to

touch or damage the front oil seal.

——To take out 7 M6 bolts (as indicated by the

arrows in the figure).

——To demount the oil pump cover plate.

D-6