Loader Bobcat 773. Manual - part 112

HANDLE CONTROL UNIT TEST (Cont’d)

Procedure (Cont’d)

Left Handle Test With Test Harness;

Raise the operator cab. (See Page 1–1.)

Connect the remote start switch. (See Page 1–1.)

The test harness (MEL1555) and a digital multimeter are

necessary to complete the following procedure.

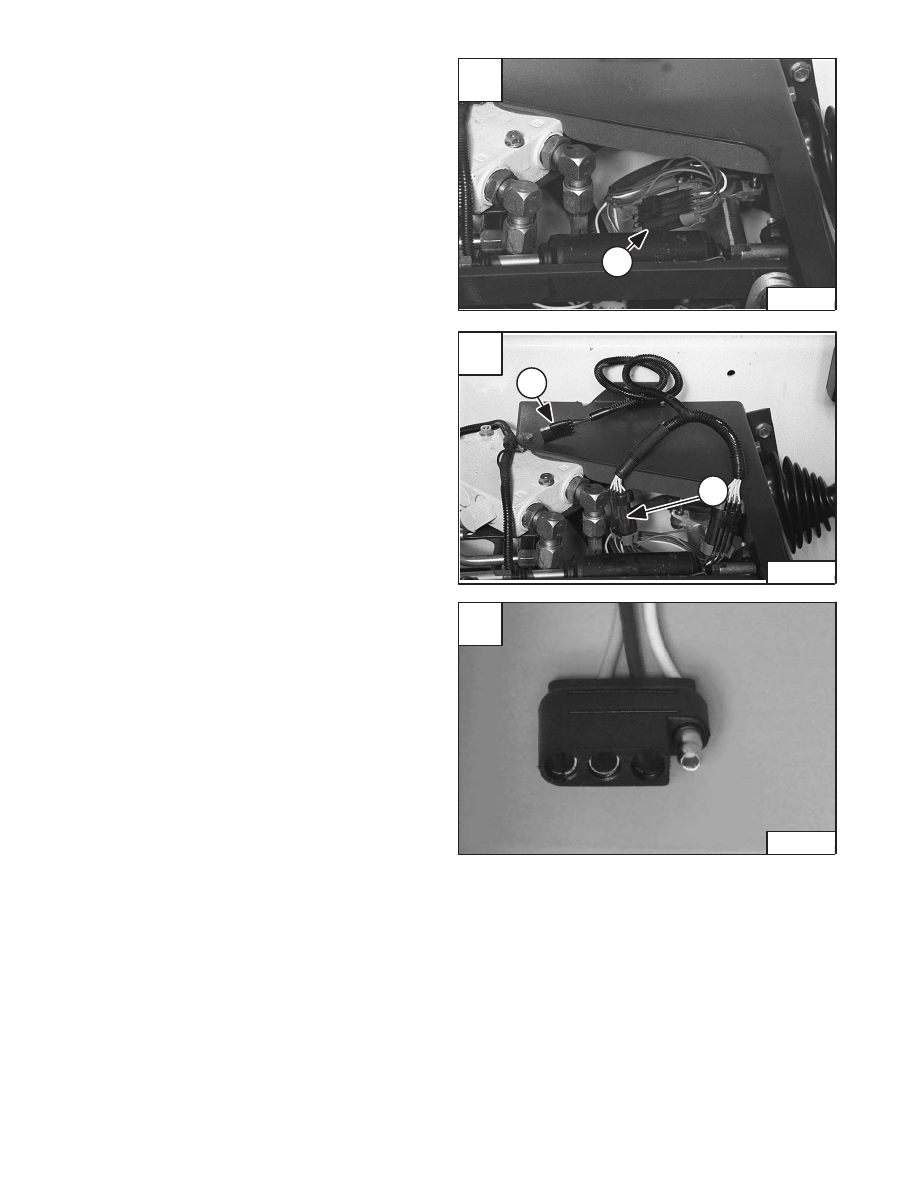

Disconnect the handle control harness (Item 1) [A].

Install the test harness (Item 1) [B].

Move handle to the neutral position.

Turn the key to the ON position with the engine OFF.

With a digital multimeter take a voltage reading at the four

prong terminal connector (Item 2) [B].

The sensor supply voltage between ground, terminal 1

and terminal 3 [C] should be 4.3

±

0.1

volts (5.0

±

0.1

volts Hall–Effect).

The signal voltage reading between the ground, terminal

1 and terminal 2 [C] should be 1.7 to 2.1 volts (1.97 to 2.44

volts*).

NOTE: Terminal 4 [C] is an open terminal not used at

this time.

Left Handle Test Without Test Harness;

A digital multimeter is necessary to complete this test.

For the switch handle harness connector color code. (See

Page 10–24.)

The test must be run at the eight pin switch handle

connector (Item 1) [A]. The wiring harness connectors

must remain connected to complete this test.

Check the sensor supply voltage (4.3

±

0.1

volts) (5.0

±

0.1

volts*) between terminal G (Brown/Black) and

terminal F (Brown/Red).

Check the signal voltage between terminal G

(Brown/Black) and terminal H (Brown/Green). The

voltage should be between 1.7 to 2.1 volts (1.97 to 2.44

volts*).

Diagnosis Results for both Tests;

If the sensor supply voltage is 4.3

±

0.1

volts (5.0

±

0.1

volts*), continue on and check the signal voltage.

If the sensor supply voltage is less than 4.3

±

0.1

volts

(5.0

±

0.1

volts*) or 0 volts, check the PWM fuse, check

for shorts or opens in the wiring harness. If there are no

apparent shorts or opens change the AHC/PWM

controller. (See Page 10–15.)

If the sensor supply voltage is more than 4.3

±

0.1

volts

(5.0

±

0.1

volts*) check for a short to a power wire in the

wiring harness. If there are no apparent shorts, change

the AHC/PWM controller. (See Page 10–15.)

If the signal voltage is in the range of 1.7 to 2.1 volts (1.97

to 2.44 volts*) the system is functioning properly. The

nominal voltage reading is 1.89 volts (2.2 volts*). If the

signal voltage is not in the range of 1.7 to 2.1 volts (1.97

to 2.44 volts*) change the handle controller.

* Hall–Effect (Identified by yellow push button float

switch on left–hand handle.

B

P–17771

1

2

1

A

N–17770

–10–12–

Service Manual

773 BICS Loader

Revised Nov. 01

C

P–13754

1

3

2

4