Lotus Eleven/Elise/Exige. Manual - part 29

Page 10

Lotus Service Notes

Section DH

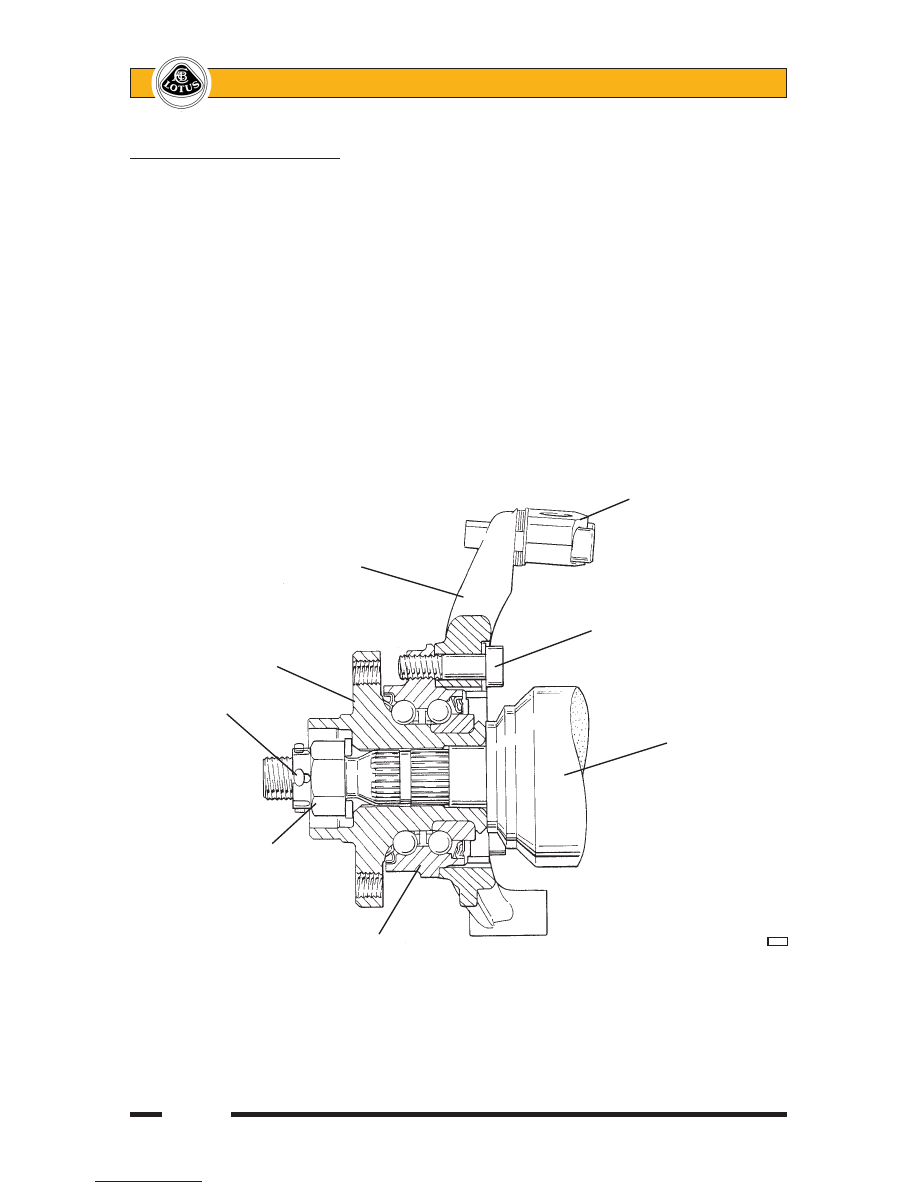

Top ball joint plinth

Hub carrier

Hub to carrier fixing bolt

Hub

Split pin

Driveshaft

Castellated nut

Double row ball bearing

d39

To Replace Hub Bearing Assembly

1. With the wheel removed, apply the parking brake, remove the split pin from the nut retaining the driveshaft

in the hub, and release the nut.

2. Release the two fixing bolts, and remove the brake caliper from the hub carrier. Support clear of the brake

disc without straining the flexible hose. Release the single countersunk screw and withdraw the brake

disc from the hub.

3. Disconnect the wheel speed sensor harness from the hub unit.

4. Using a Torx socket, release the three bolts securing the hub bearing unit to the hub carrier, and withdraw

the unit from the hub carrier and driveshaft. If necessary, use a suitable puller tool to press the shaft from

the hub, but on no account allow an extension force to be applied to the driveshaft.

5. Fit the new hub bearing unit in reverse order to disassembly, with the following notes:

- Torque tighten the three Torx bolts securing the hub bearing assembly to the hub carrier to 90 Nm.

- Torque tighten the driveshaft nut to 220 Nm and retain using a new split pin.

- Pump the brake pedal to reposition the pads before driving the car.