Haima S5. Chassis System. Service Manual - part 2

Wheels and tires 2C-5

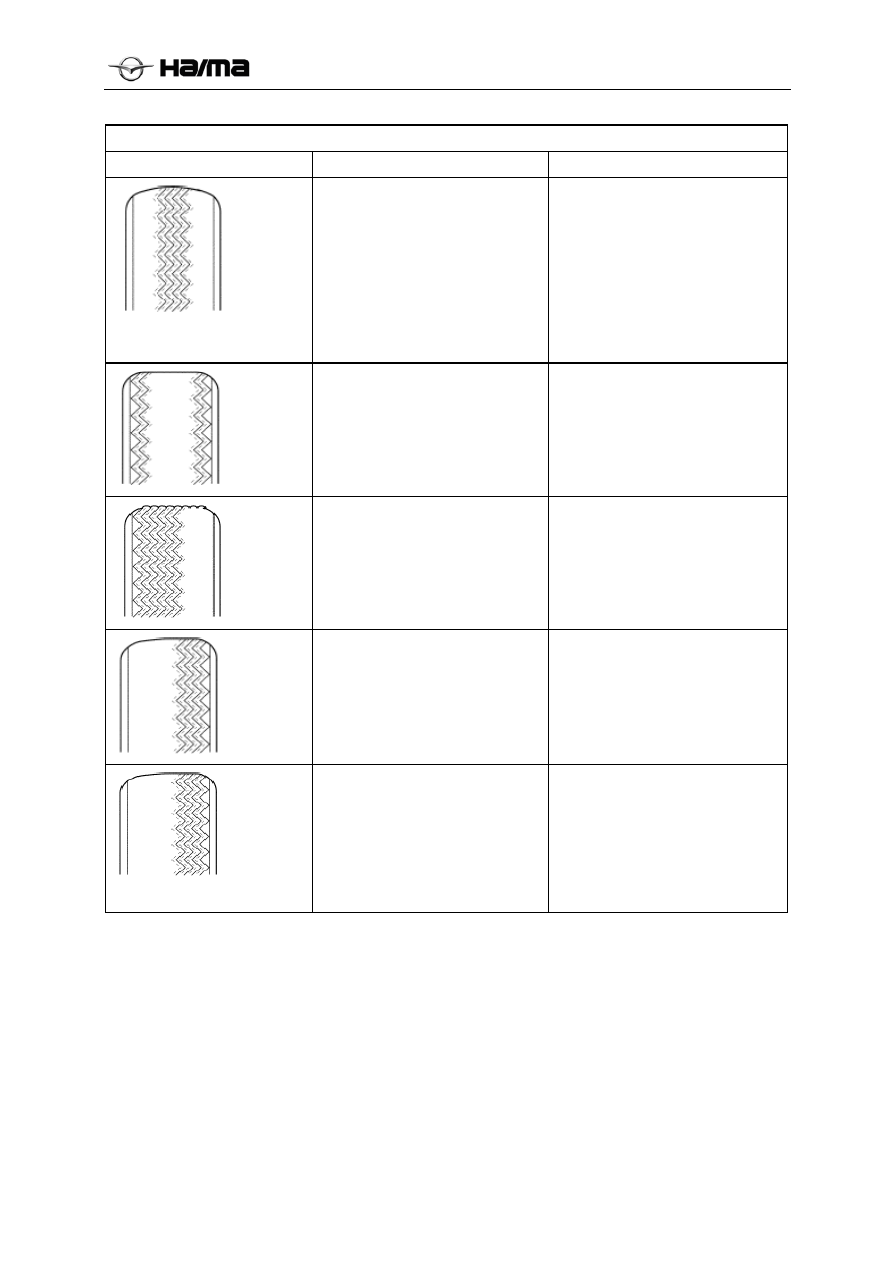

Irregular or excessive wears of tire

Fault

Possible causes

Corrective measures

●

Overlow tire pressure

●

Improper tire rotation

●

Adjust the tire pressure.

●

Rotate the tire.

●

Overhigh tire pressure

●

Improper tire rotation

●

Adjust the tire pressure.

●

Rotate the tire.

●

Improper toe-in

●

Adjust the toe-in.

●

Reverse toe-in

●

Adjust the toe-in.

●

Improper kingpin caster angle

or improper front-wheel

camber

●

Suspension failure

●

Improper wheel balance

●

Improper tire rotation

●

Check the steering knuckle,

control connecting rod, drive

shaft and suspension. Replace

if necessary.

●

Adjust the balance of wheel.

●

Rotate the tire.