Haima S5 1.5T. A/C, Restraint System, Body Accessories, Electrical System. Manual - part 8

Electrical System 3D-16

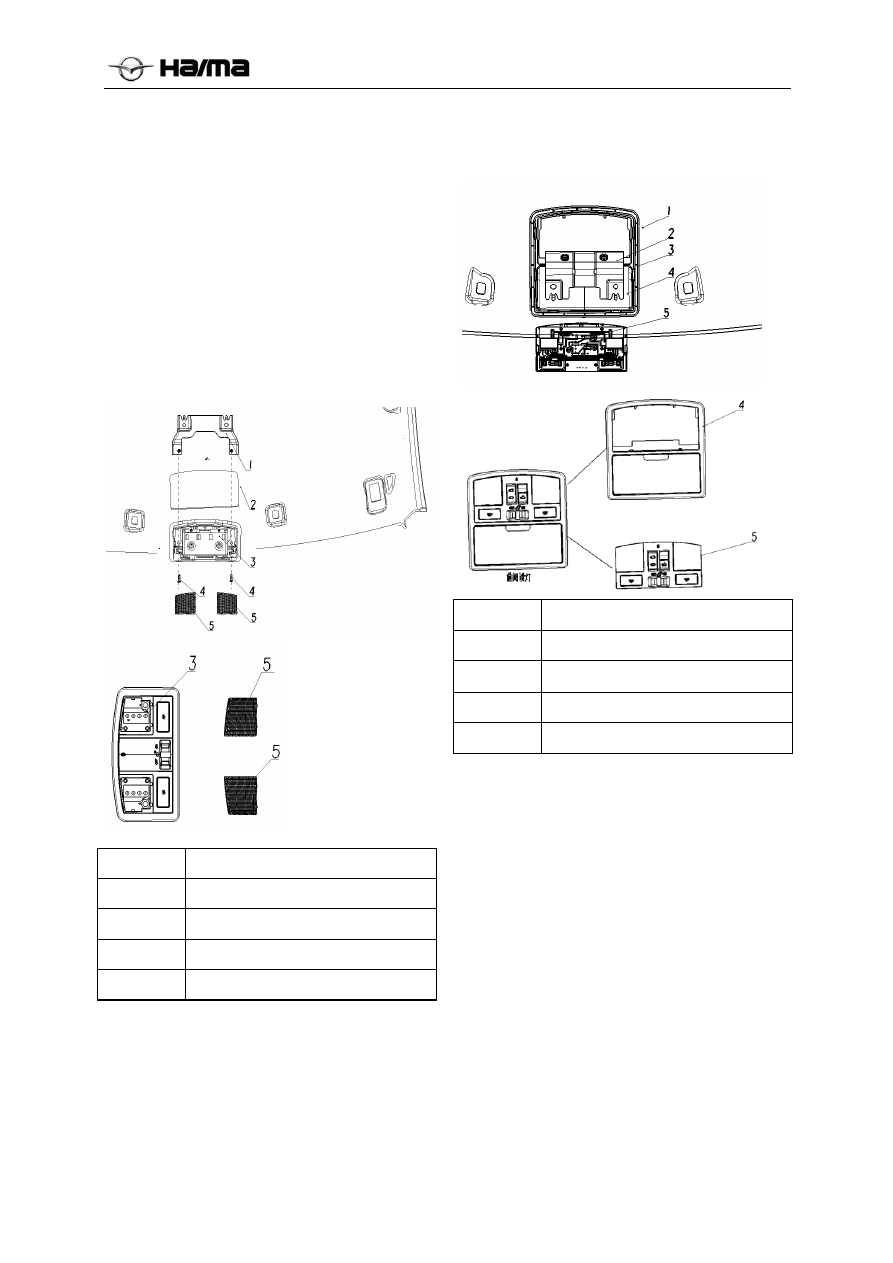

Interior Lamp

Removal/Installation of Front Reading

Lamp (low version)

1. Remove the negative cable of the battery.

2. The reading lamp shade lamp body upturned

former interior lights out with a slotted

screwdriver.

3. Use a Phillips screwdriver to two self-tapping

screws on the lamp housing removed.

4. Remove

the

connector.

5. Perform the installation in reverse order of the

removal.

1 Reading

lamp

bracket

2 Roof

body

3

Low distribution front reading lamps

4 Self-tapping

screws

5 Reading

lamp

shade

Removal/Installation of Front Reading

Lamp (High version with glasses box)

1. Remove the negative cable of the battery.

2. The reading lamp shade lamp body upturned

former interior lights out with a slotted

screwdriver.

4. Remove the connector. To replace the wick.

5. Perform the installation in reverse order of the

removal.

1 Roof

body

2 Body

bracket

3

Reading lamp bracket

4

Front reading lamp body

5

Front reading lamp wick

Note: When the production assembly, the first line

under the reading lamp light body frame fitted with

front reading lights on the ceiling, then along the

ceiling to install the lamp body stuck in the body

iron bracket. Then plug in the connectors, the

reading lamp wick fasten the lamp body.

Removal/Installation of Rear Interior

Lamp (low version)

1. Remove the negative cable of the battery.

2. Dome lamp shade after Alice out with a slotted

screwdriver.

3. Use a Phillips screwdriver to attach the two lock

bolts removed.

4. Remove the connectors.

5. Replace the rear interior lamps.

After the ceiling bracket is glued to the ceiling,

with the ceiling supplied together, contrary

installation and removal order.