Haima S5 1.5T. A/C, Restraint System, Body Accessories, Electrical System. Manual - part 2

A/C System3A-16

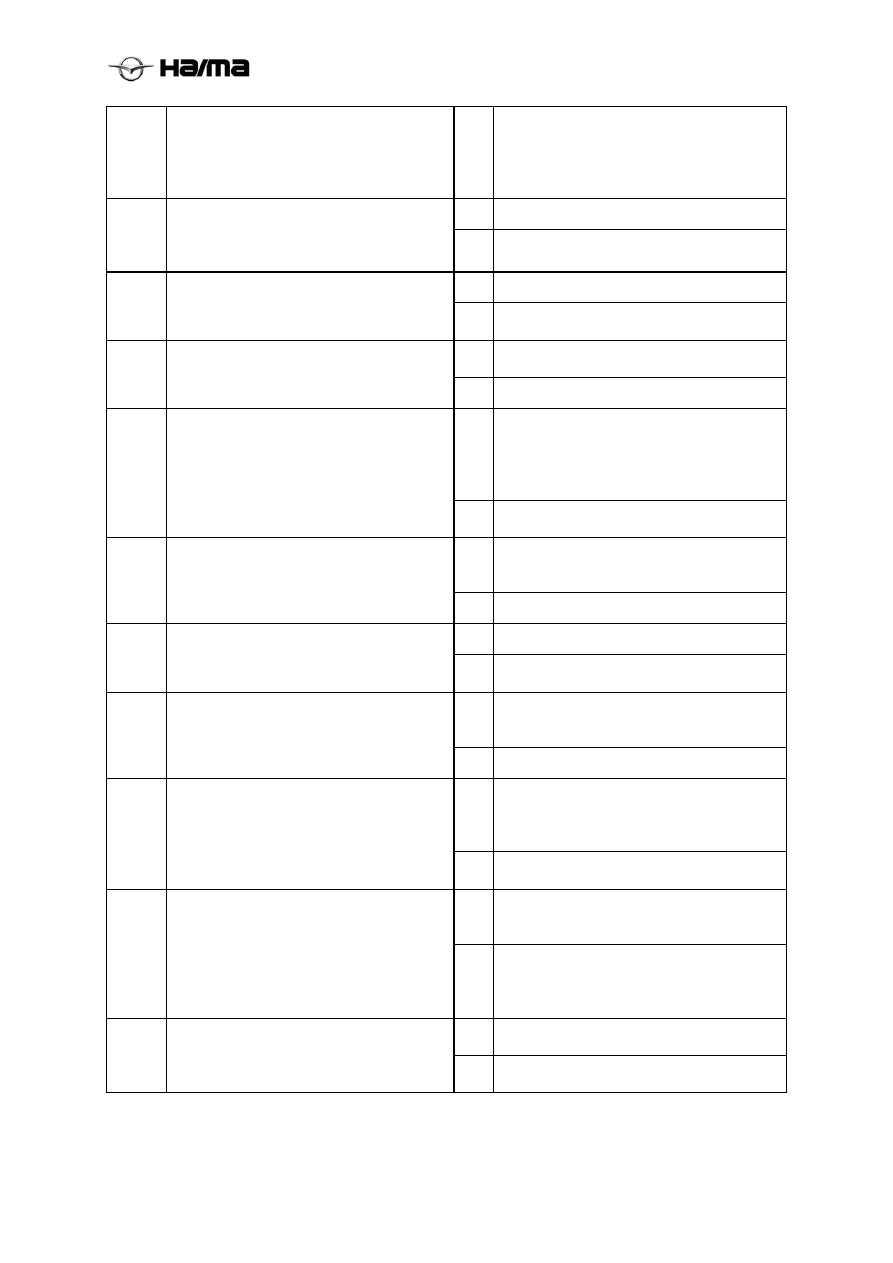

No

If the pipeline or A/C parts are damaged or

fissured, replace them, and then go to the

step 19. If there is air leakage, repair or

replace the connector, replace the

receiver/dryer and then go to the step 19.

Yes Go to the next step.

10

Add the 20ml{20cc.0.8fl oz} compressor

oil.

Can any noise be heard under the high

operation of the engine?

No

End the fault diagnosis and explain the

repair details to the customer.

Yes Go to the next step.

11

Drain the compressor oil.

Is there any metallic particulate pollutant?

No

Replace the A/C compressor and then go to

the step 19.

Yes

Replace the entire A/C system (except for

the heater) and then go to the step 19.

12

Is the compressor oil whitened or be mixed

with water?

No

Go to the next step.

Yes

Replace the A/C compressor and the

receiver/dryer (because the A/C compressor

may be worn and the receiver/dryer may be

blocked, it is necessary to replace them) and

then go to the step 19.

13

Is there any click sound? (the operating

noise of the electromagnetic clutch)

No

The condition is normal and recheck the

fault symptom.

Yes

Replace the A/C compressor, and then go to

the step 19.(A/C compressor drain valve is

kept open)

.14

Can you hear any noise right after the A/C

compressor stops?

No

Go to the next step.

Yes Go to the next step.

15

Is the drive belt normal?

Refer to Checking the Drive Belt, Drive

Belt, Section B.

No

Adjust or replace the drive belt and then go

to the step 19.

Yes

Remove the sundries and greasy dirt or

replace the drive belt, and then go to the step

19.

16

Is the drive belt worn? Is there any attached

sundries? Is there any greasy dirt?

No

Go to the next step.

Yes

Replace the A/C compressor (except for the

electromagnetic clutch pressure plate, the

belt pulley and the coil) and then go to the

step 19.

17

Is the electromagnetic clutch normal?

Refer to Checking the Electromagnetic

Clutch, Control System.

No

Replace the electromagnetic clutch and then

go to the step 19.

Yes

Visually check the A/C compressor and

replace relevant parts when necessary, and

then go to the next step.

18

Is the noise from the A/C compressor?

No

If the noise is caused by the refrigerant

pipeline, repair the loosened or missed clips

and tighten the screws, and then go the next

step.

Yes

End the fault diagnosis and explain the

repair details to the customer. .

19

Does the noise stop out of the A/C

compressor?

No

If the fault reoccurs, recheck the fault

symptom and start from the step 1.