Snowmobile Arctic Cat 2-Stroke (2007 year). Manual - part 158

9-145

9

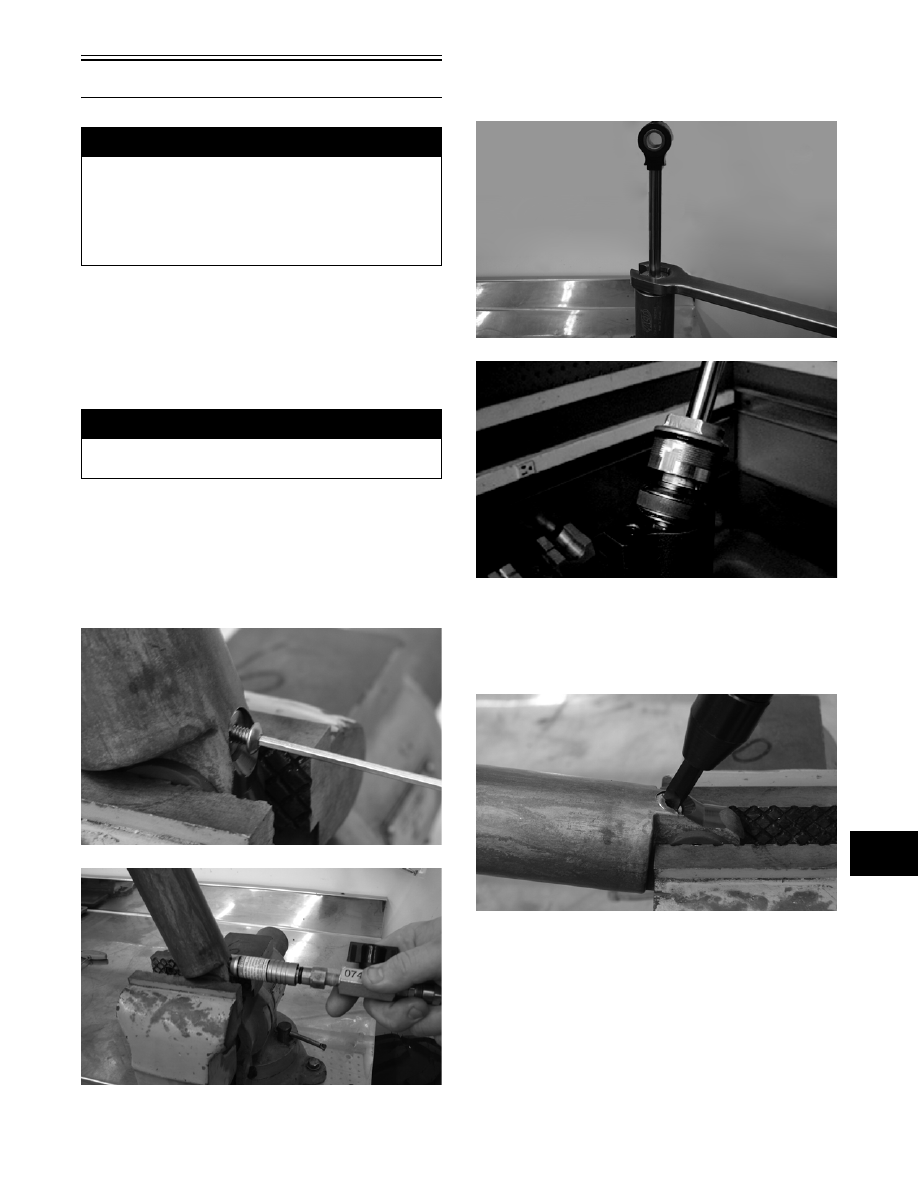

Servicing ACT Shock

REMOVING/CLEANING

1. Remove the shock from the snowmobile.

2. Wash the shock body in parts-cleaning solvent;

then dry with compressed air to remove sand and

dirt.

DISASSEMBLING

1. Remove the screw from the pressure valve assem-

bly on the bottom of the shock. Discharge all the

pressure from the shock using the Inflation Needle

(p/n 0744-020). Open the valve in filler handle

until all pressure is released.

FS250

FS251

2. Using a 1-in. wrench, loosen the bearing assembly

and remove the shock rod and valve assembly

from the shock body.

FS252

FS055

3. Pour the oil from the shock body into a suitable

container.

4. Remove the pressure valve assembly. Account for

the O-ring.

FS253

5. Using IFP Installation/Location Tool (p/n 0644-

348), remove the floating piston.

! WARNING

Before any service is performed on the gas shock

absorber, first discharge all pressure from the shock

remote reservoir. Remove the valve screw from the

pressure valve and insert the Inflation Needle (p/n

0744-020). Open valve until all pressure is released.

Failure to do this may cause personal injury.

! WARNING

When using compressed air to dry components,

always wear safety glasses.