Snowmobile Arctic Cat 2-Stroke (2007 year). Manual - part 140

9-73

9

FS249A

3. Place a support stand under the rear bumper; then

while holding the flared bushing, remove the rear

cap screws securing the skid frame to the tunnel.

Account for lock washers and flat washers.

NOTE: The support stand should hold the snow-

mobile level but not raised off the floor.

4. Remove the front cap screws securing the skid

frame to the tunnel. Account for a flat washer and

a lock washer.

5. Remove the support stand; then tip the snow-

mobile onto one side using a piece of cardboard to

protect against scratching. Remove the skid frame.

MS132

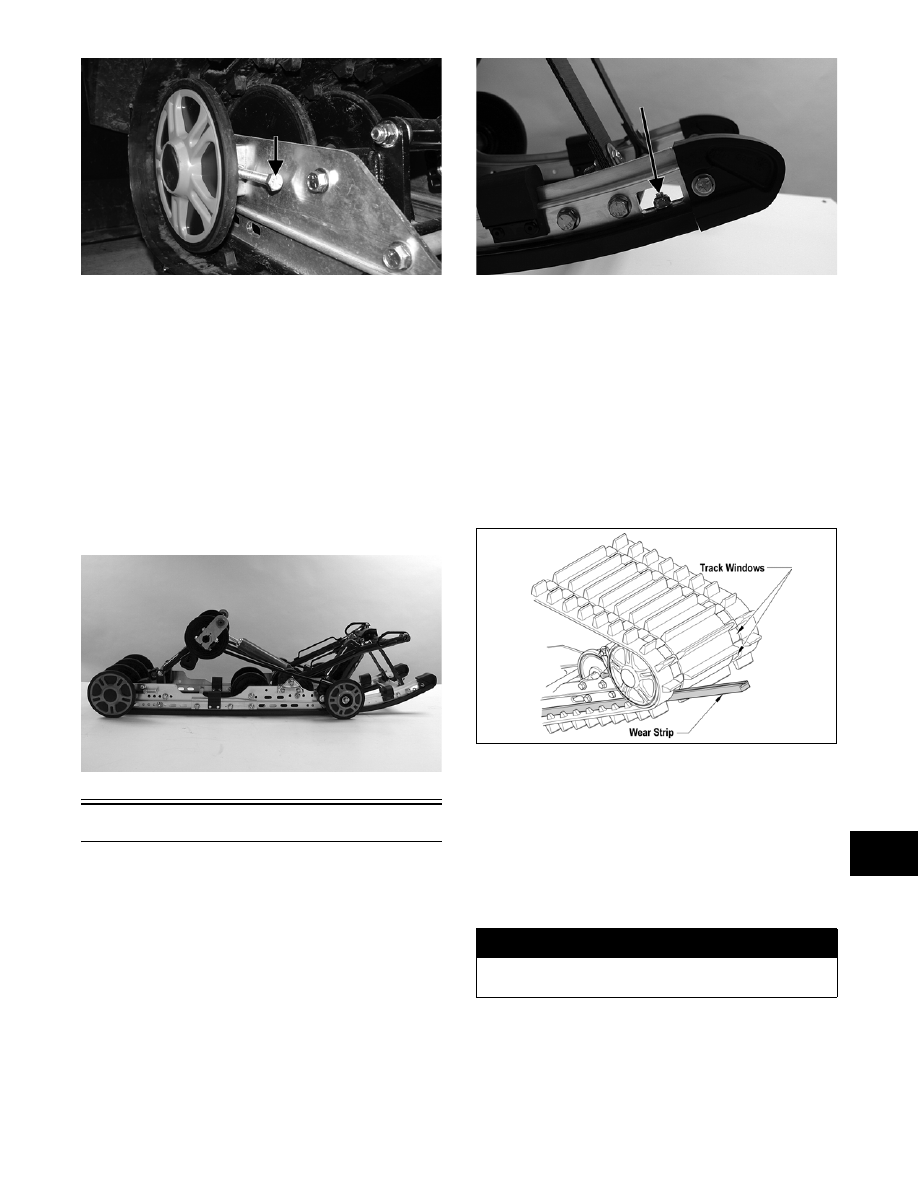

Wear Strips

REMOVING

NOTE: The skid frame does not have to be

removed for this procedure; however, if wear strip

binding or slide rail damage has occurred, the skid

frame should be removed for this procedure (see

Removing Skid Frame in this sub-section).

1. Remove the machine screw and lock nut securing

the wear strip to the front of the slide rail.

MS016B

NOTE: If the skid frame has been removed due to

difficulty in removing the wear strip, it may be nec-

essary to use a pipe wrench, start from either end,

and hook the edge of the wear strip with the pipe

wrench jaw and twist the wear strip off the slide

rail. Move the pipe wrench 7.5 cm (3 in.) and again

twist the wear strip off the rail. Repeat this proce-

dure until the wear strip is free of the rail.

2. Align the wear strip with the openings (windows)

in the track; then using a suitable driving tool,

drive the wear strip rearward off the slide rail.

739-884A

CLEANING AND INSPECTING

NOTE: Whenever a part is worn excessively,

cracked, or damaged in any way, replacement is

necessary.

1. Clean the slide rail using parts-cleaning solvent

and compressed air.

2. Inspect the slide rail for cracks. If any cracks are

found, replace the slide rail.

! WARNING

Always wear an approved pair of safety glasses

when using compressed air.