Snowmobile Arctic Cat 2-Stroke (2007 year). Manual - part 61

4-18

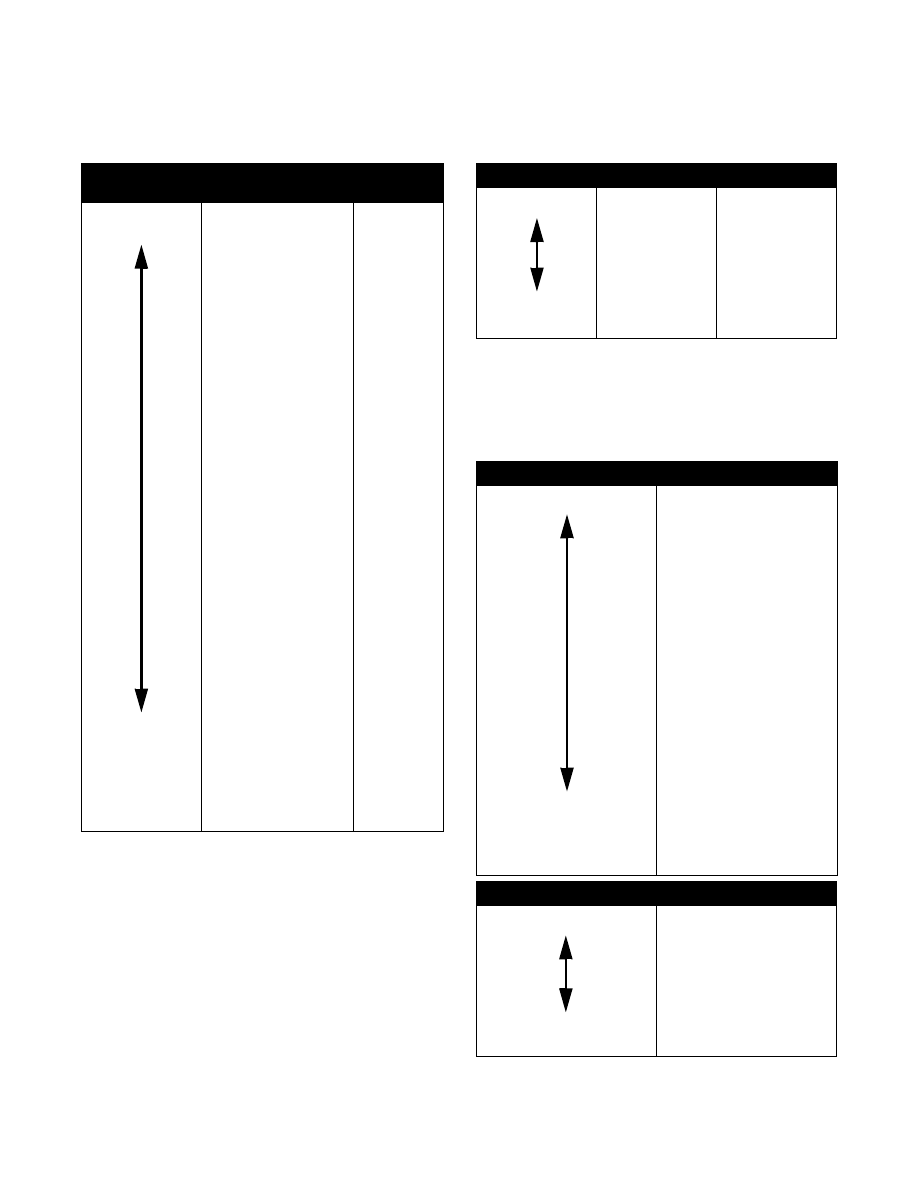

Major Tuning Components

To assist you in selecting four major tuning components of the carburetor, listed below are the jet needles, needle

jets, pilot jets, and piston valves on charts according to their size.

NOTE: The above needle jets may come in dif-

ferent types; for example, (159) - (166) - (480) -

(224). When selecting a new needle jet, use the

correct series or type.

NOTE: The above chart shows the average per-

formance of a given needle between 1/4 and 3/4

throttle. Needles are constructed in such a way

that at any given point, the needle could be richer

or leaner than the rating it has.

NEEDLE JETS

TYPE - 159-166-480

VM30-32-34-38

TYPE 224

VM40-44

LEAN

N-4

N-6

N-8

O-0

O-2

O-4

O-5

O-6

O-7

O-8

P-0

P-2

P-4

P-5

P-6

P-8

Q-0

Z-0

Q-2

Z-5

Q-3

Z-6

Q-4

Z-8

Q-5

AA-0

Q-6

AA-1

Q-8

AA-2

R-0

AA-3

R-2

AA-5

R-4

AA-8

R-5

BB-0

R-6

BB-5

RICH

R-8

JET NEEDLES

LEAN

6DH2

7F7

6DH3

7DH2

6DH4

7F6

6DH7

7DH3

6DH8

7DH5

6DH41

7H2

RICH

6EGJ1

7J2

PILOT JETS

LEAN

12.5

15

17.5

20

22.5

25

27.5

30

32.5

35

37.5

40

45

50

55

60

65

RICH

70

PISTON VALVES

LEAN

4.0

3.5

3.0

2.5

2.0

1.5

RICH

1.0