Snowmobile Arctic Cat 2-Stroke (2007 year). Manual - part 42

2-154

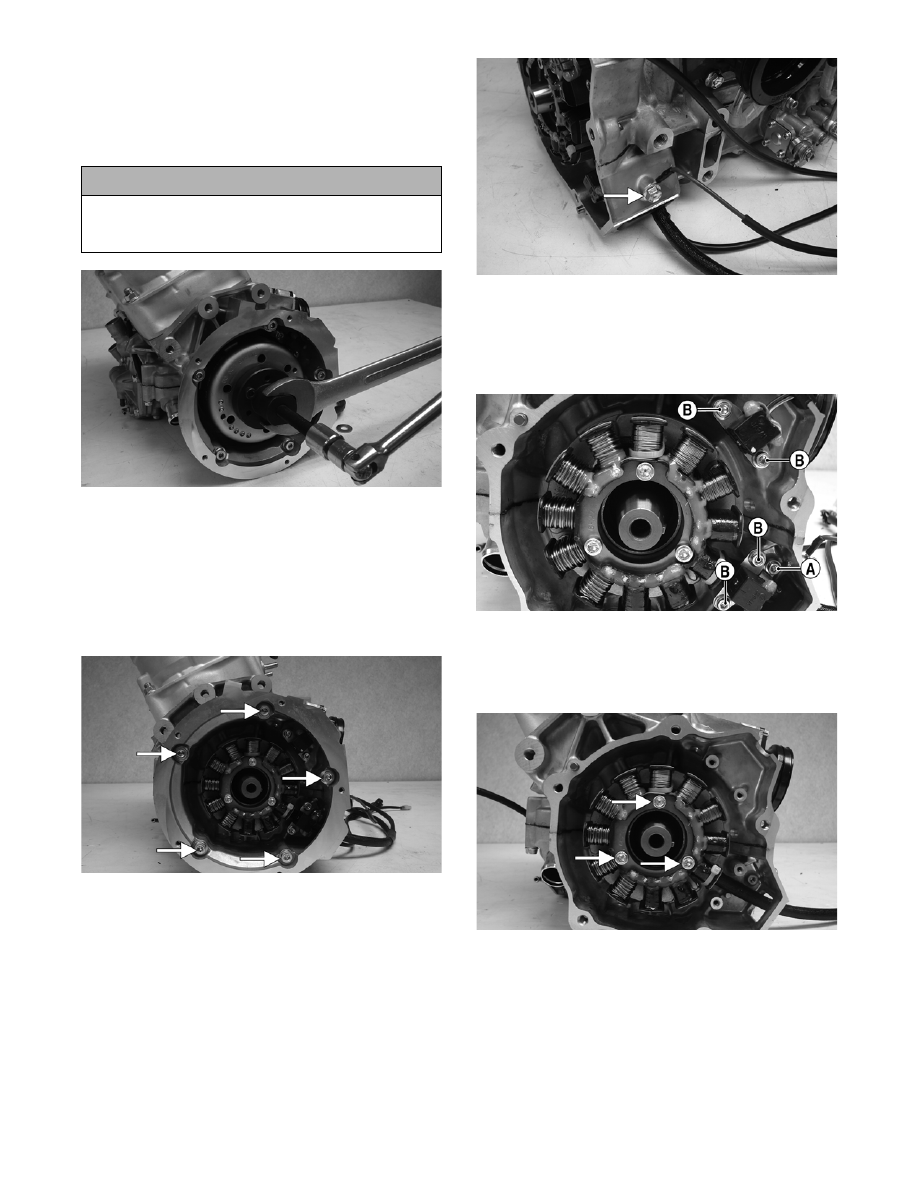

3. Using Flywheel Puller (p/n 0744-040) or suitable

substitute, remove the flywheel from the crank-

shaft by tightening the puller bolt, striking the

head of the puller bolt with a hammer, and tighten-

ing again. Repeat this procedure until the flywheel

is free. Account for the key.

CM140

NOTE: To ensure the cleanliness of the flywheel

magnets, place the flywheel (with the magnets fac-

ing upward) on a clean bench.

NOTE: On the 1000 cc, remove the Allen-head

cap screws securing the magneto case to the

crankcase. Account for four alignment pins.

CM144A

4. Remove the cap screw securing the ground wire to

the crankcase.

CM142A

5. Remove the Allen-head cap screw (A) securing

the stator lead wire plate to the crankcase; then

remove the Allen-head cap screws (B) securing

the timing sensors, remove the sensors, and

account for the harness grommets.

CM141C

6. Remove the Allen-head cap screws securing the

stator to the stator plate. Route the stator lead wire

out of the crankcase; then remove the stator

assembly.

CM143A

7. Remove the cap screws securing the stator plate to

the engine; then remove the plate.

! CAUTION

To prevent damage to the crankshaft, do not thread

puller bolts more than 12.7 mm (1/2 in.) into the fly-

wheel. Damage to the coils may result.