Snowmobile Arctic Cat 2-Stroke (2007 year). Manual - part 36

2-130

4. Place the cylinder heads on a Surface Plate (p/n

0644-016) covered with #400 grit wet-or-dry

sandpaper. Using light pressure, move each cylin-

der head in a figure eight motion. Inspect the seal-

ing surface for any indication of high spots. A high

spot can be noted by a bright metallic finish. Cor-

rect any high spots before assembly by continuing

to move the cylinder head in a figure eight motion

until a uniform bright metallic finish is attained.

CM018

CYLINDERS

1. Using a non-metallic carbon removal tool, remove

carbon buildup from the exhaust ports.

2. Wash the cylinders in parts-cleaning solvent.

3. Inspect the cylinders for pitting, scoring, scuffing,

and corrosion. If marks are found, repair the sur-

face with an appropriate ball hone and honing oil

(see chart).

NOTE: To produce the proper 60° crosshatch pat-

tern, use a low RPM drill (600 RPM) at the rate of 30

strokes per minute. If honing oil is not available,

use a lightweight, petroleum-based oil. Thoroughly

clean the cylinders after honing using detergent

soap and hot water and dry with compressed air;

then immediately apply oil to the cylinder bores. If

a bore is severely damaged or gouged, the cylin-

der will have to be replaced.

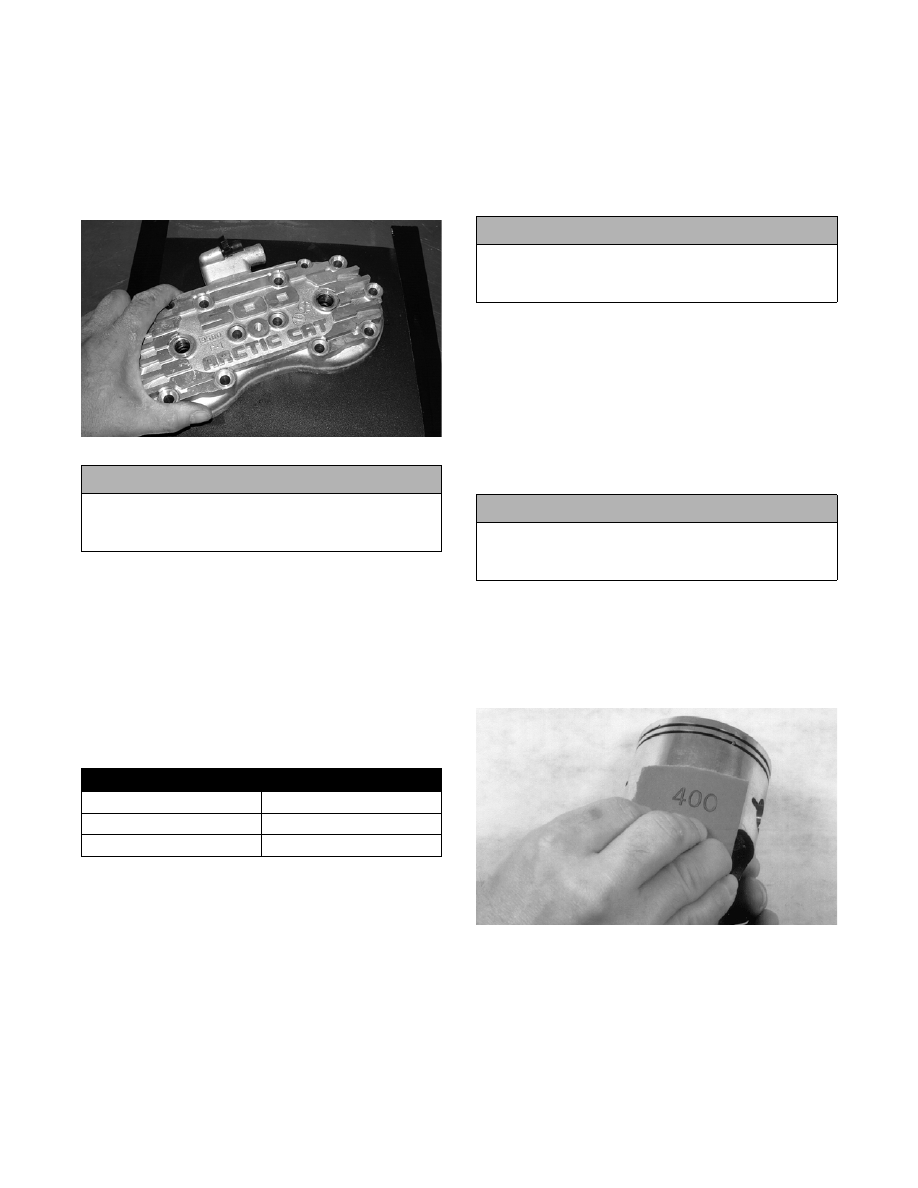

4. Place the head surface of each cylinder on the sur-

face plate covered with #400 grit wet-or-dry sand-

paper. Using light pressure, move each cylinder in

a figure eight motion. Inspect the surface for any

indication of high spots. A high spot can be noted

by a bright metallic finish. Correct any high spots

before assembly by continuing to move the cylin-

der in a figure eight motion until a uniform bright

metallic finish is attained.

PISTON ASSEMBLY

1. Using a non-metallic carbon removal tool, remove

the carbon buildup from the dome of each piston.

2. Take an old piston ring and snap it into two pieces;

then grind the end of the old ring to a 45° angle

and to a sharp edge. Using the sharpened ring as a

tool, clean carbon from the ring-grooves. Be sure

to position the ring with its tapered side up.

3. Inspect each piston for cracks in the piston pin and

skirt areas.

4. Inspect each piston for seizure marks or scuffing.

Repair with #400 grit wet-or-dry sandpaper and

water or honing oil.

AN135

NOTE: If scuffing or seizure marks are too deep

to correct with the sandpaper, it will be necessary

to replace the piston.

5. Inspect the perimeter of each piston for signs of

excessive “blowby.” Excessive “blowby” indicates

worn piston rings or an out-of-round cylinder.

! CAUTION

Water or parts-cleaning solvent must be used in

conjunction with the wet-or-dry sandpaper or dam-

age to the sealing surface may result.

BALL HONES

Engine Size

p/n

500 cc

0644-291

600 cc

0644-292

! CAUTION

Water or parts-cleaning solvent must be used in

conjunction with the wet-or-dry sandpaper or dam-

age to the sealing surface may result.

! CAUTION

Improper cleaning of the ring-grooves by the use of

the wrong type of ring-groove cleaner will result in

severe damage to the piston.