Snowmobile Arctic Cat 2-Stroke (2007 year). Manual - part 14

2-42

MD0090

MD0092A

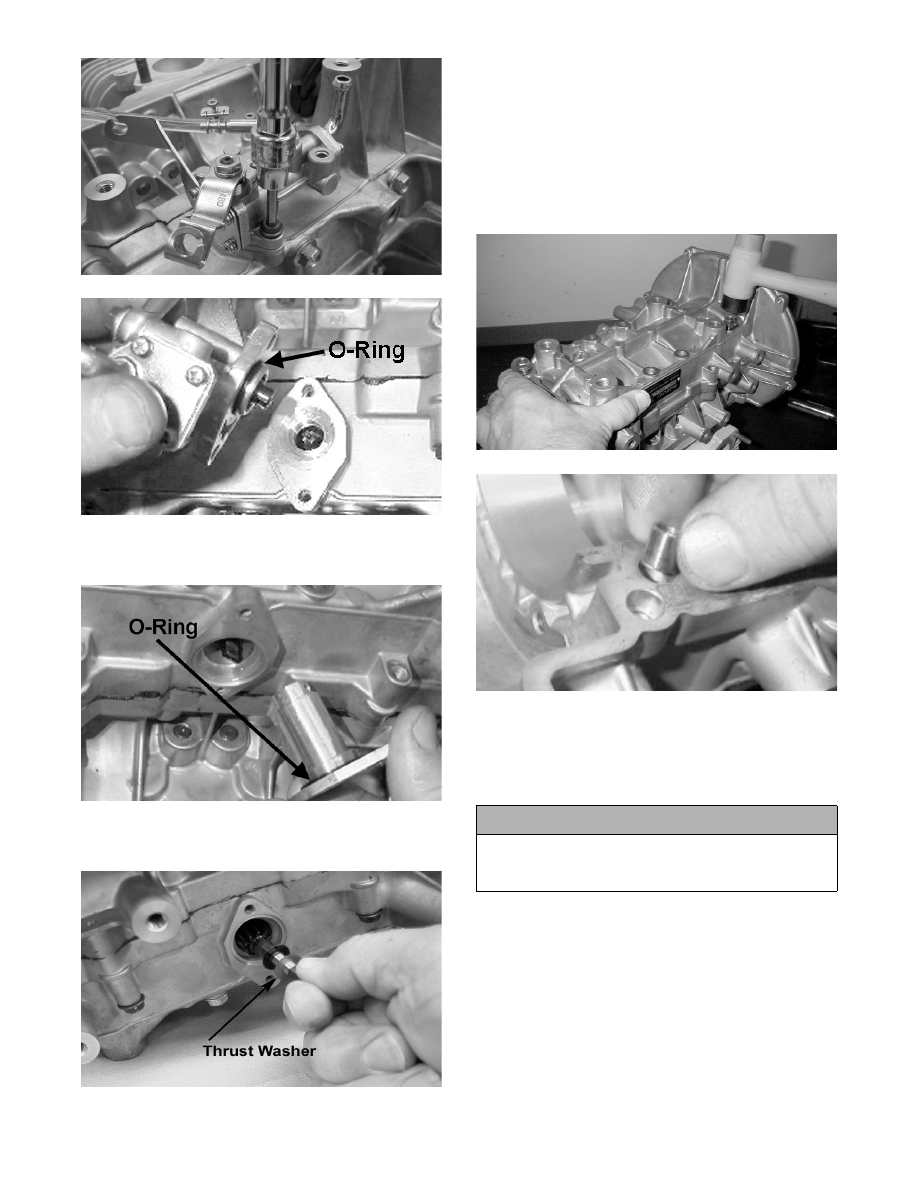

20. Remove the oil-injection pump driveshaft retainer.

Account for an O-ring.

MD0100A

21. Remove the oil-injection pump driveshaft.

Account for a thrust washer.

MD0101

22. Place the crankcase (with its bottom side up) on

two blocks of wood. Remove the 12 cap screws

securing the crankcase halves. Note the position of

the different-sized cap screws.

23. Separate the crankcase halves by installing two of

the cap screws in opposite corners leaving the heads

approximately 6 mm (1/4 in.) out. Using a plastic

mallet, tap on each cap screw until the crankcase

halves separate. Account for four dowel pins.

MD0283

MD0204

24. Remove the two cap screws; then remove the

crankshaft assembly from the upper crankcase half

making sure to hold both ends of the crankshaft to

keep the bearings and seals from falling off.

Account for bearings and a C-ring.

! CAUTION

To prevent damage to the crankshaft, crankshaft

bearings, or seals, be sure to always lift the crank-

shaft from both ends.