Snowmobile Arctic Cat 2-Stroke (2007 year). Manual - part 9

2-22

370-ENG07A

16. Lift the engine out of the engine compartment.

17. Remove the cap screws, washers, and lock wash-

ers securing the engine mounting brackets to the

engine; then remove the brackets.

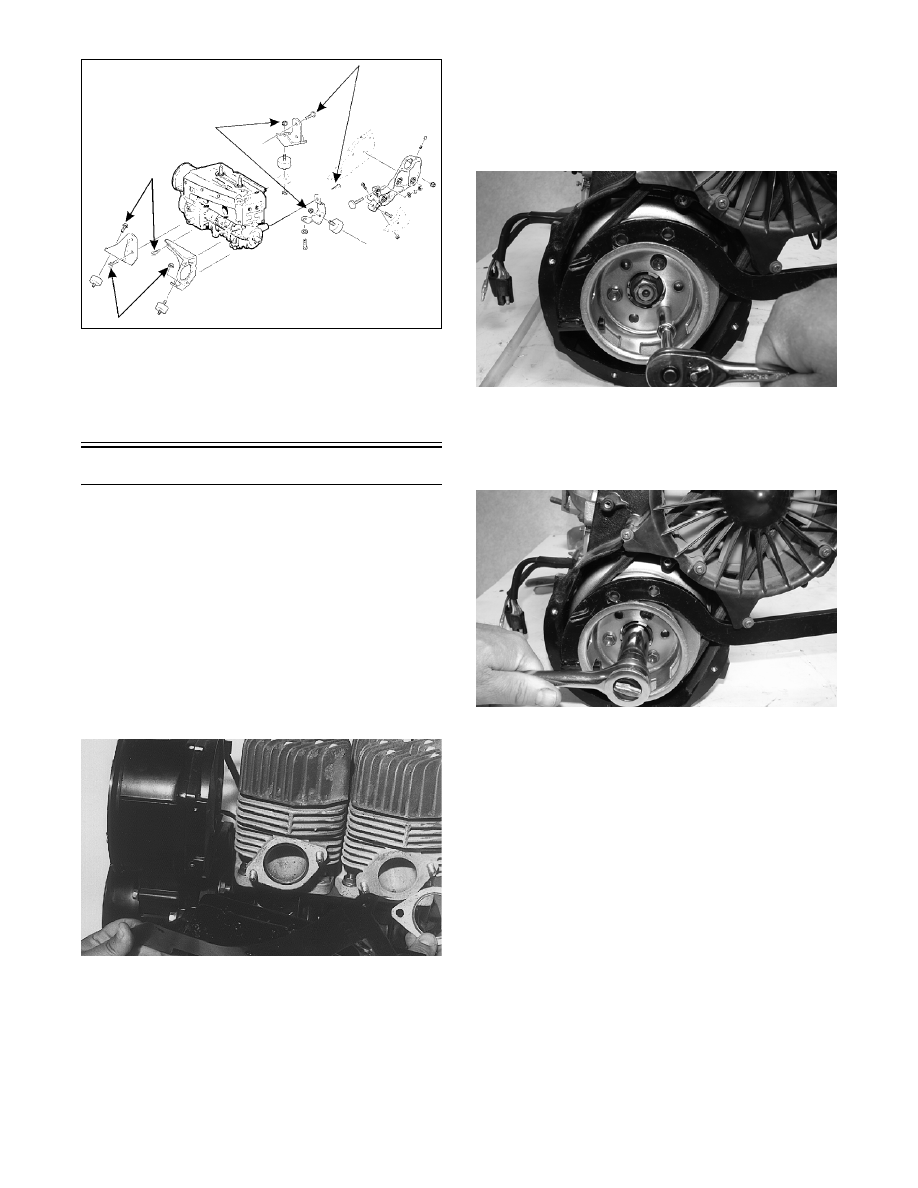

Disassembling Engine

1. Remove the four nuts and lock washers securing

the exhaust manifold; then remove the exhaust

manifold. Account for two gaskets.

2. Noting the location of the longer cap screws for

assembly purposes, remove the 14 cap screws,

lock washers, and washers securing the top and

exhaust-side cooling shrouds.

3. Lift the top cooling shroud off the engine and slide

the exhaust-side cooling shroud off the exhaust-

manifold studs. Account for two exhaust-manifold

shroud gaskets.

AB014

4. Disconnect the two oil-injection hoses from their

fittings on the intake manifold.

5. Remove the nuts securing the intake manifold;

then remove the manifold with flange from the

engine. Account for two insulators. Discard the

gaskets.

6. Remove the intake-manifold cooling shroud from

the engine. Discard the two gaskets.

7. Using Flywheel Spanner Wrench (p/n 0144-007)

to secure the crankshaft, remove the three cap

screws and lock washers securing the starter pul-

ley to the flywheel. Remove the starter pulley;

then carefully pry the fan belt drive pulley from its

seated position on the flywheel and remove.

MD2494

8. Temporarily install the starter pulley on the fly-

wheel with three cap screws. Using the flywheel

spanner wrench to secure the crankshaft, loosen

and remove the flywheel nut and washers.

MD2495

NOTE: If an impact wrench is being used, use of

a flywheel spanner wrench will not be necessary.

9. Remove the cap screws securing the starter pulley

to the flywheel and remove the pulley.

10. Remove the flange nuts securing the fan case to

the crankcase; then remove the fan case.

NOTE: For further servicing of the axial fan com-

ponents, see section 3.