Snowmobile Arctic Cat (2009 year). Manual - part 19

MAINTENANCE

69

743-439A

4. Position the console onto the air-

intake silencer; then secure with the

single torx-head screw beneath the

console (located between the head-

lights).

5. Install the two torx-head screws

located to the outside of the head-

light adjustment knobs; then

tighten securely.

6. Check headlight aim (see Adjust-

ing Headlight Aim in this sub-sec-

tion).

Adjusting Headlight

Aim

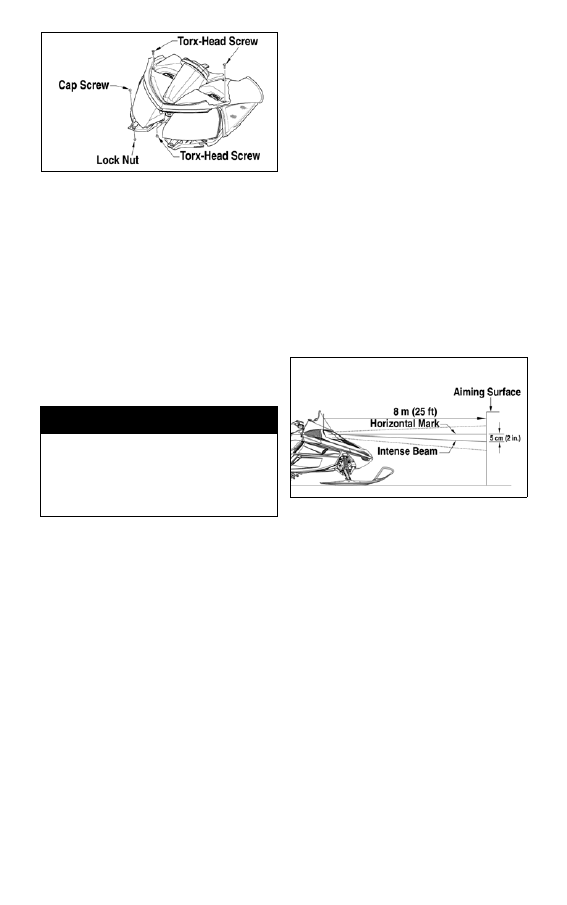

The headlight can be adjusted for verti-

cal aim of the HIGH/LOW beam. The

geometric center of HIGH beam zone

is to be used for vertical aiming.

1. Position the snowmobile on a level

floor so the headlight is approxi-

mately 8 m (25 ft) from an aiming

surface (wall or similar surface).

NOTE: There should be an “aver-

age” operating load on the snow-

mobile when adjusting headlight

aim.

2. Measure the distance from the

floor to midpoint of the headlight.

3. Using the measurement obtained

in step 2, make a horizontal mark

on the aiming surface.

4. Make a vertical mark which inter-

sects the horizontal mark on the

aiming surface directly in front of

the headlight.

5. Engage the brake lever lock and

start the engine. Move the head-

light dimmer switch to the HIGH

beam position. DO NOT USE

LOW BEAM.

6. Observe the headlight beam aim.

Proper aim is when the most

intense beam is centered on the

vertical mark 5 cm (2 in.) below

the horizontal mark on the aiming

surface.

0741-448

7. Adjust the headlight using the

adjustment knobs until correct aim

is obtained. Shut the engine off;

then disengage the brake lever

lock.

! WARNING

Do not operate the snowmobile

unless headlight beam is adjusted

properly. An incorrectly adjusted

beam will not provide the operator

the optimum amount of light.