Snowmobile Arctic Cat (2009 year). Manual - part 16

MAINTENANCE

57

Also, drive belts have a break-in period

of approximately 20 miles. After

installing a new drive belt, drive the

snowmobile for 20 miles at 1/2 throttle

or less. This will allow the drive belt to

gain its optimum flexibility and will

extend drive belt life.

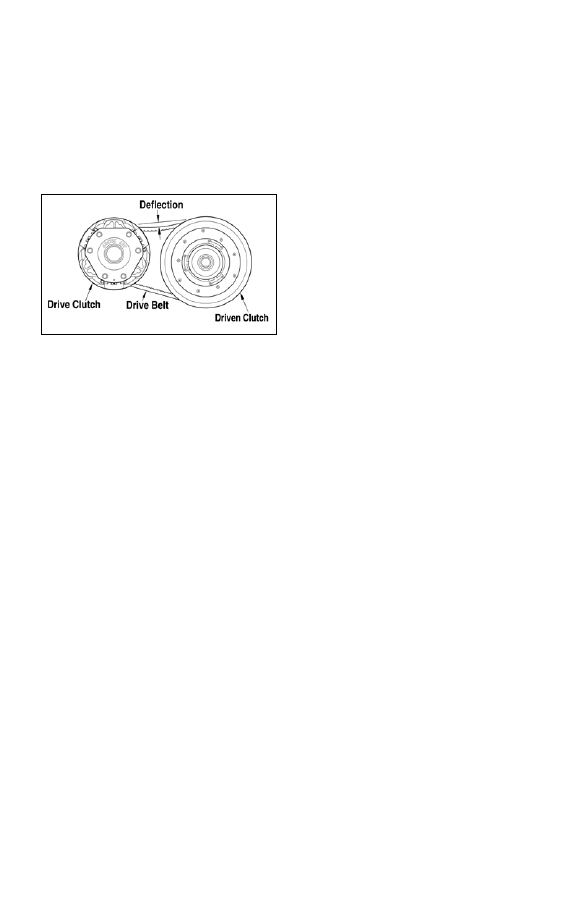

Checking/Adjusting

Drive Belt Deflection

0743-319

The drive belt must have the proper fit

in the drive clutch and driven pulley.

To check for proper drive belt fit, use

the following procedure.

1. Place a straightedge on the top of

the drive belt. The straightedge

should reach from the drive clutch

to the top of the driven pulley.

NOTE: Make sure the drive belt

is all the way out in the driven pul-

ley before checking drive belt fit.

2. Using a stiff ruler centered

between the drive clutch and

driven pulley, push down on the

drive belt just enough to remove

all slack and note the amount of

deflection. The deflection should

be within the range of 28.5-31.8

mm (1 1/8-1 1/4 in.).

3. To correct drive belt deflection,

remove the sheave adjuster from

the pulley, remove or add shim

washers to the adjuster, and install

the adjuster.

NOTE: Adding shim washers will

decrease belt deflection and remov-

ing shim washers will increase belt

deflection. Available shim washers

from Arctic Cat are p/n 0648-714

(0.090 in.) - one included in the tool

kit, p/n 0648-715 (0.030 in.), and p/n

0648-716 (0.060 in.).

NOTE: Removing/adding shim

washers may be done by the snow-

mobile owner if qualified to do so.

If the owner does not feel qualified,

take the snowmobile to an autho-

rized Arctic Cat Snowmobile dealer

for this service. This service is at

the discretion and expense of the

snowmobile owner.

Removing Drive Belt

NOTE: Changing a drive belt can

be done by the snowmobile owner

if qualified to do so. If the owner

does not feel qualified, take the

snowmobile to an authorized Arc-

tic Cat Snowmobile dealer for this

service. This service is at the dis-

cretion and expense of the snow-

mobile owner.

1. Turn ignition key to the OFF posi-

tion and wait for all moving parts

to stop.

2. Set the brake lever lock.

3. Open the left-side access panel;

then remove the belt guard.

4. Remove the cap screw, lock

washer, washer, and sheave

adjuster from the end of the driven

pulley.

NOTE: Assure that the shims

and O-ring are not removed from

the adjuster.