Snowmobile Arctic Cat (2008 year). Manual - part 64

2-194

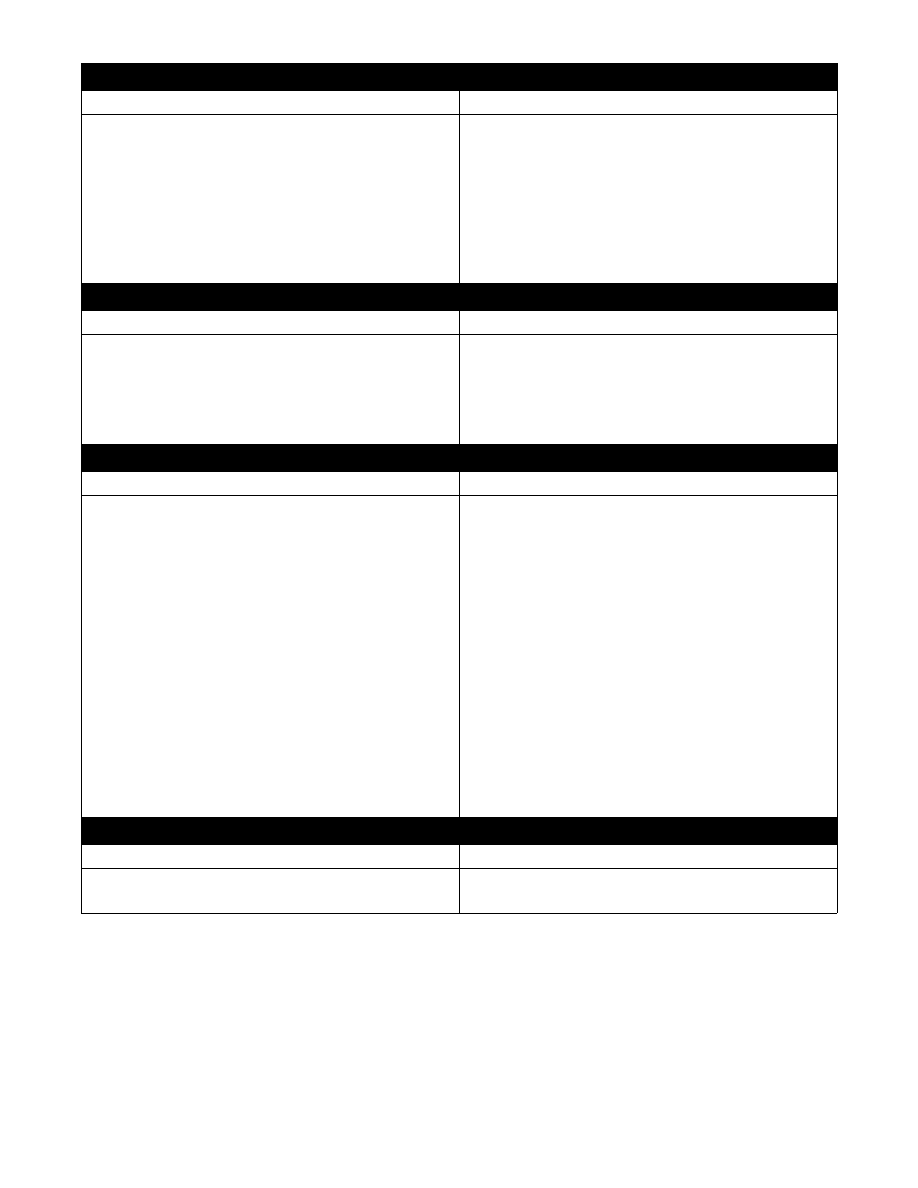

Problem: Engine Backfires

Condition

Remedy

1. ECU/CCU LED trouble code

2. Throttle/ignition monitor switch adjusted incorrectly

3. Spark plugs fouled — damaged

4. High tension leads/coil shorting

5. ECU/CCU faulty — damaged

6. Fuel mixture lean

7. Oil-injection pump malfunctioning — adjusted incor-

rectly

1. Service — replace problem component

2. Adjust throttle cable tension — service spring

3. Clean — replace spark plugs

4. Service — replace high tension leads/coil

5. Replace ECU/CCU

6. Repair fuel regulator — injector(s)

7. Replace — bleed — adjust oil-injection pump

Problem: Engine Four-Cycles (Floods Excessively)

Condition

Remedy

1. ECU LED trouble code

2. Fuel pressure too high

3. Injector faulty

4. Throttle position sensor faulty

5. Air-intake silencer obstructed

1. Service — replace problem component

2. Replace regulator — hose

3. Replace injector

4. Replace throttle body assembly

5. Remove obstruction

Problem: Engine Stops Suddenly

Condition

Remedy

1. Gas tank empty

2. Spark absent

3. ECU/CCU LED trouble code

4. CDI relay faulty

5. Fuel filter(s) obstructed

6. Fuel pressure low

7. Fuel pump faulty

8. Fuel pump relay faulty

9. Gas tank vent hose obstructed

10. ECU/CCU faulty

11. Fuel hose obstructed — broken — pinched

12. Ignition coil faulty

13. Engine seized

14. Throttle/ignition monitor switch — throttle cable

tension faulty — adjusted incorrectly

1. Fill tank

2. See No Spark at Spark Plugs sub-section

3. Service — replace problem component

4. Replace CDI relay

5. Replace filter(s)

6. Replace regulator — hose

7. Service — replace fuel pump

8. Replace relay

9. Service vent hose

10. Replace ECU/CCU

11. Remove obstruction — repair — replace fuel hose

12. Replace ignition coil

13. Service engine

14. Replace throttle control — adjust throttle cable

Problem: Engine Fails to Stop (Continues to Run, Even with All Switches Off)

Condition

Remedy

1. ECU/CCU shorted to ground

2. Engine wiring harness connections wet

1. Replace ECU/CCU

2. Clean — dry connections