Snowmobile Arctic Cat (2007 year). Manual - part 97

9

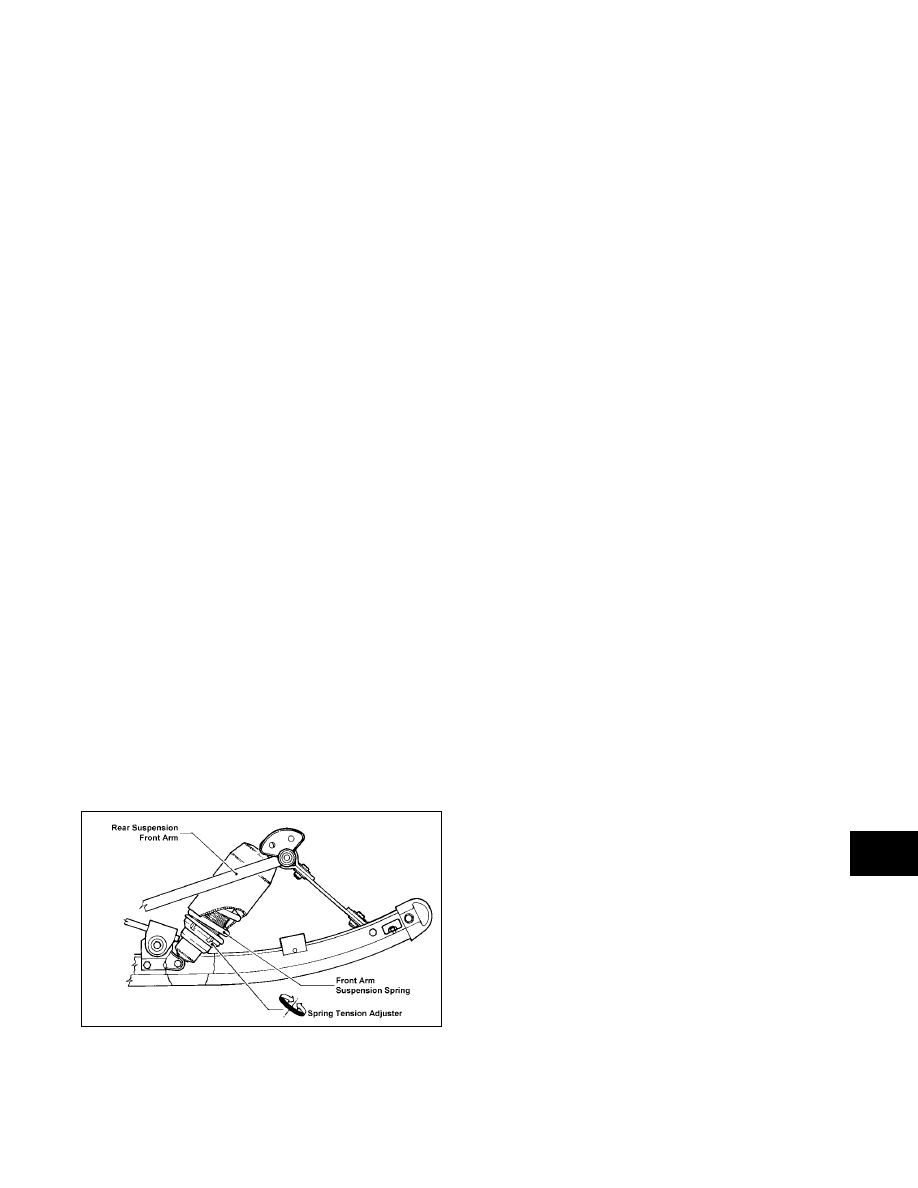

SUSPENSION SETUP BASICS

FRONT ARM SPRING TENSION

NOTE: Read the following information closely as

it pertains to all suspensions used in the last sev-

eral years. If there are any questions, please con-

tact the Arctic Cat Service Department.

It is desirable to run with very light front arm spring

tension. When riding in 4 in. or more of snow, the

machine will be quicker if the front spring tension is

adjusted lightly.

If the spring tension is adjusted too stiff, the track

angle at the front of the skid frame is steep. This

steep angle prevents the snowmobile from getting

up on plane and slows down by 5 to 8 mph.

When riding in sticky snow (springtime or warm

days) or hill climbing on hard snow, it may be desir-

able to stiffen the front arm spring tension. When

this is done, weight is transferred back quicker. The

problem with too much front arm spring tension is

that the feel of the snowmobile becomes very short.

The reason for this is the front arm becomes the

pivot point between the spindles and rear of the

machine. With dominant spring tension on the front

arm, the suspension is basically contacting the snow

from a point below the front arm to the skis or the

spindle pressure point. This makes for a very short

and darting machine on the trail. This is especially

true when decelerating and the center of gravity is

transferred forward.

A good method for adjusting the front spring tension

follows.

NOTE: On those models having a coil spring

over the front arm shock absorber, the spring ten-

sion should be set as soft as possible when oper-

ating on trails and in deep snow.

0729-662

FRONT ARM LIMITER STRAPS

Under no circumstances should the front arm limiter

strap be lengthened. If lengthened, it may cause

shock absorber travel problems.

The two limiter straps can be shortened if desired.

This adjustment must be made to suit driving style

and some test driving time. With the rear arm in its

present mounting location, no advantage has been

noted from changing the strap length. If the front

arm straps are shortened, the result will be more ski

pressure and aggressive steering.

SKI SHOCK ABSORBER SPRINGS

The shock absorber springs have been matched to

the shock valving and rear suspension. These

springs are the result of hours of testing and compar-

ison riding trying many different combinations of

springs and shocks. If there is a need to make

changes, there are several spring and shock sizes to

choose from. While making these changes, keep the

following points in mind.

Heavier Or Stiffer Springs

1. These will require shocks with more rebound

control, or the front end will become like a pogo

stick.

2. With stiffer springs, the front end will become

more aggressive in the corners as more weight

will be transferred to the skis when decelerating.

Also, more weight is transferred to the rear on

acceleration and can cause the rear shocks and

spring to bottom out.

3. If the springs are too stiff for general riding con-

ditions and style, the ride comfort is gone.

Spring Tension Too Soft

1. Front end bottoms out; hard on front end parts.

2. Less aggressive steering in corners on decelera-

tion, and less weight is transferred to the skis

because of softer springs.

3. Less weight gets transferred to rear of the

machine upon acceleration.