Snowmobile Arctic Cat (2004 year). Manual - part 63

5-19

5

To check battery condition, use a digital volt/ohmme-

ter set on DC volt scale. Test between the adjustment

tool black and red jacks. Insert the red lead of the digi-

tal voltmeter into the red jack of the adjustment tool

and the black lead of the digital voltmeter into the

black jack of the adjustment tool. If voltage is found

below 4.9 volts, replace the battery.

1. Using TPS Adjustment Tool (p/n 0644-299),

connect its wiring harness to the TPS. Connect the

two digital voltmeter leads (red and black) using

the two pin jack adapters provided with the

adjustment tool to the white and black jacks of the

TPS adjustment tool.

2. Ensure that the throttle cable has the proper

amount of free-play.

3. With the throttle in the idle position, compare the

reading on the voltmeter to the chart. If the reading

is at the prescribed specification, proceed to step 6.

If the reading is not at the prescribed specification,

proceed to step 4.

4. Using TPS Screwdriver (p/n 0644-344), loosen the

two retaining screws securing the TPS to the

throttle body.

5. Adjust the TPS to obtain the correct idle position

reading; then tighten the two retaining screws

securely.

6. Depress the throttle lever slowly. The meter

reading should show a smooth rise all the way to

wide-open throttle. Repeat this step until it is

assured that there are no open areas or “peaks” in

the reading.

7. Disconnect the adjustment tool harness from the

TPS. Connect the snowmobile TPS harness to the

newly installed or adjusted TPS.

NOTE: Before installing the TPS harness con-

nector, apply dielectric grease to the connector

pins.

REPLACING TPS (Carb Models)

NOTE: On EFI models, the TPS is not a service

part. The throttle body w/sensor must be replaced.

1. Disconnect the throttle cable from the throttle

shaft.

2. Turn the idle adjustment screw counterclockwise

until it is not in contact with the throttle lever.

3. Disconnect the TPS wiring harness connector.

Using TPS Screwdriver (p/n 0644-344), remove

the two retaining screws securing the TPS to the

carburetor/throttle body.

4. Install the new TPS and secure with two retaining

screws, flat washers, and lock washers.

5. Adjust the TPS using the appropriate procedures

in this sub-section.

FAIL-SAFE IGNITION TIMING

Engines equipped with throttle position sensor have a

protective feature called “fail-safe” ignition timing

which prevents engine damage should the TPS fail. If

the TPS does fail, the engine will run normally at low

RPM but will run poorly at high RPM. This will allow

the operator to get the snowmobile to safety with little

or no engine damage.

NOTE: The engine will continue to operate this

way until the TPS is replaced.

Testing Electrical

Resistances

(EFI Models)

NOTE: Resistance tests of the engine electrical

components should be made using the Fluke Mul-

timeter only. Analog-style multitesters may not be

accurate enough to use in these critical tests.

Replace any component that does not have a test

value within specifications.

IGNITION COIL (Primary)

1. Disconnect the double wire plug from the ECU to

the ignition coil.

2. Set the selector in the X1 position.

3. Connect the red meter lead to the black/orange

lead; then connect the black meter lead to the

orange/black lead.

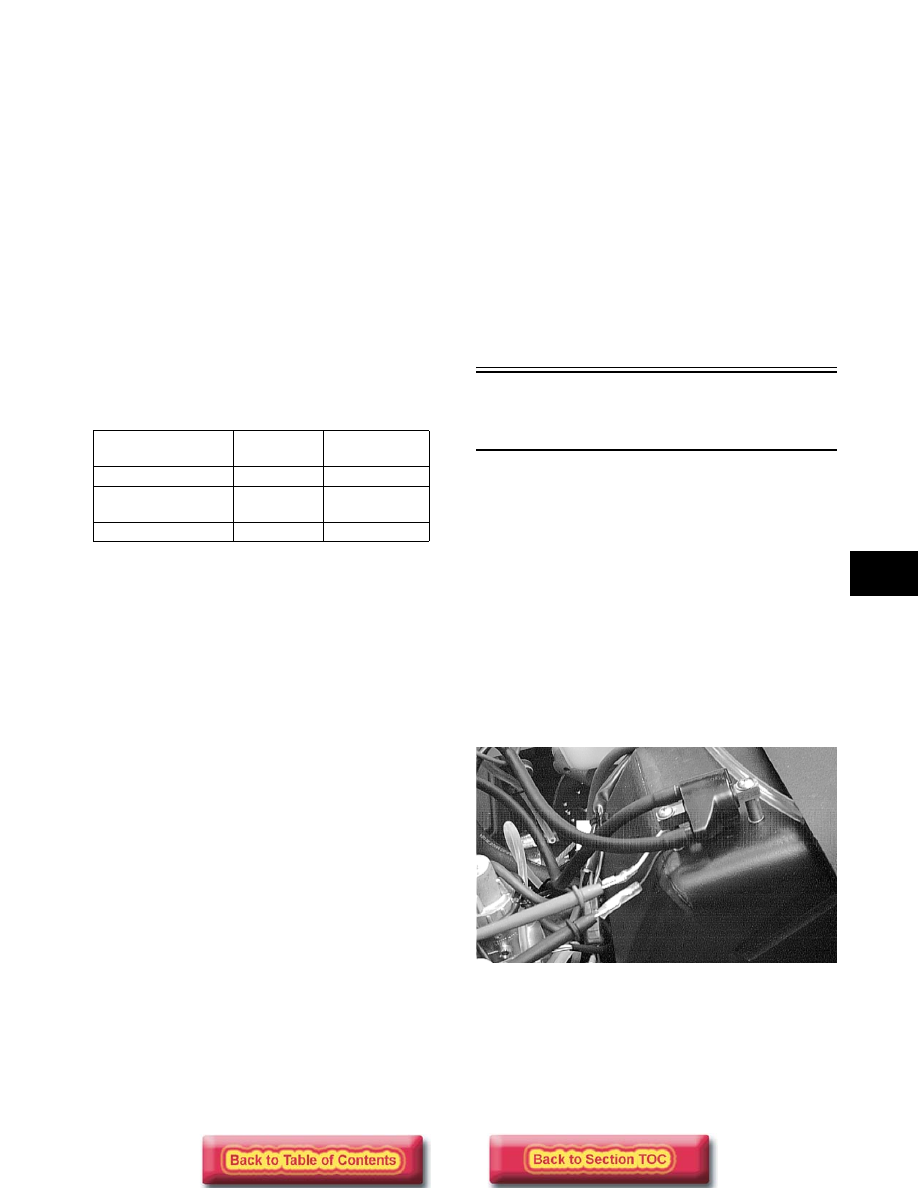

AK051D

4. Ignition coil primary resistance must be between

0.24-0.36 ohm.

IGNITION COIL (Secondary)

1. Remove the spark-plug caps from the high tension

wires.

2. Set the selector in the X1K position.

Engine

Idle

Position

Wide-Open

Position

600 cc (STD)

0.64V

3.575-3.937V

600/700 cc

(“Laydown”)

0.69-0.71V 3.575-3.937V

800/900

0.69-0.71V 3.575-3.937V