Snowmobile Arctic Cat (2004 year). Manual - part 52

4-43

4

2. Using TPS Adjustment Tool (p/n 0644-299), con-

nect its wiring harness to the TPS. Connect the

two Fluke meter leads (red and black) using the

two pin jack adapters provided with the adjust-

ment tool to the red and black jacks of the TPS

adjustment tool.

NOTE: Before using the TPS adjustment tool,

verify its battery condition. The battery used in the

tool is a 9-volt battery. To check battery condition,

use a digital volt/ohmmeter set on DC volt scale.

Test between the adjustment tool black and red

jacks. Insert the red lead of the digital voltmeter

into the red jack of the adjustment tool and the

black lead of the digital voltmeter into the black

jack of the adjustment tool. If voltage is found

below 4.9 volts, replace the battery.

3. Set the multimeter selector to the DC scale; then

SLOWLY depress the throttle lever. The meter

reading should show a smooth rise all the way to

wide-open throttle. Repeat this step until it is

assured that there are no open areas or “peaks” in

the reading.

NOTE: If a reading contains open areas or

peaks, the throttle position sensor may be faulty.

Refer to the proper Checking/Adjusting TPS proce-

dure in Section 5 - Digital 3-D Ignition in this man-

ual.

4. Disconnect the adjustment tool harness from the

TPS. Connect the snowmobile TPS harness to the

TPS.

NOTE: Before installing the TPS harness con-

nector, apply dielectric grease to the connector

pins.

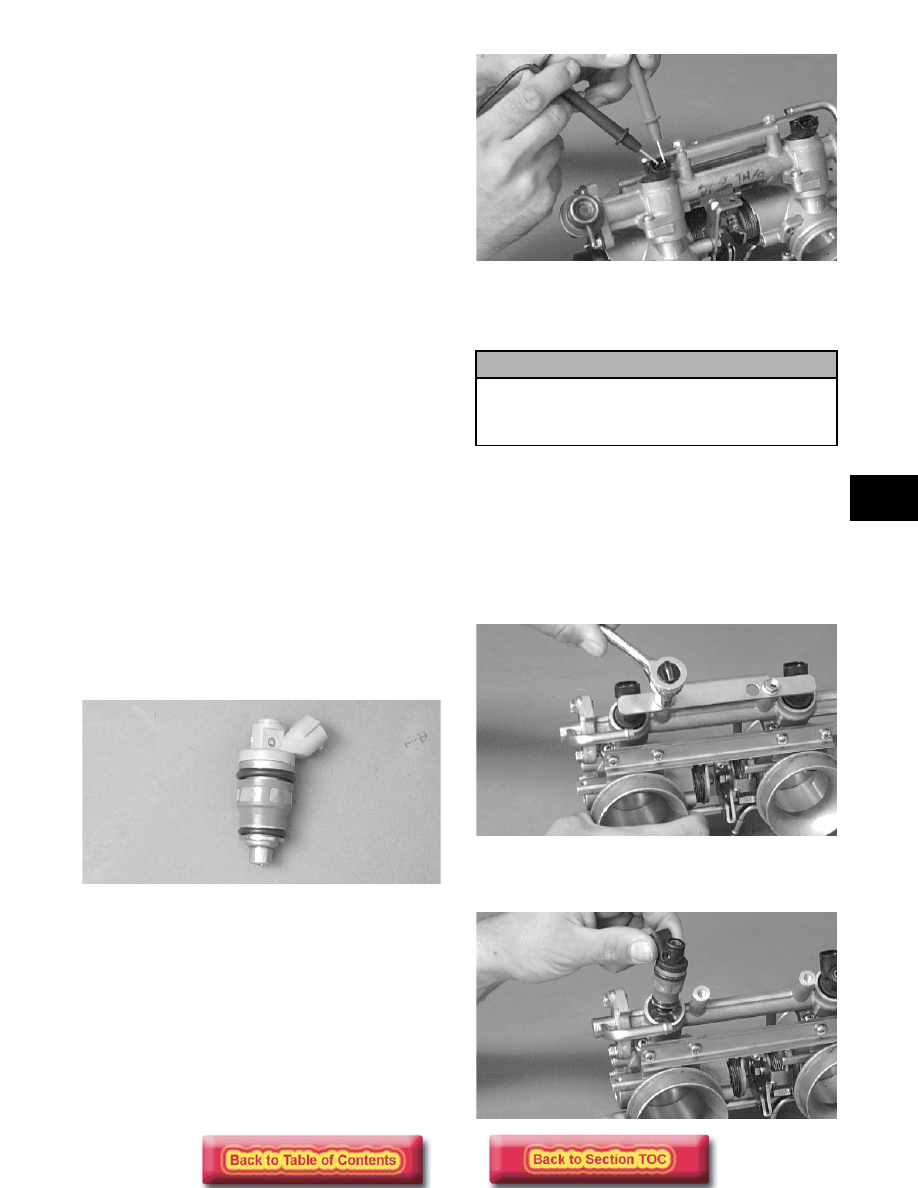

FUEL INJECTORS

AO139D

Testing Resistance/Voltage

1. Disconnect the fuel injector wiring harness.

2. Set the meter selector to the OHMS scale.

3. Test between the two injector terminals. Test

specification is 2.4-3.3 ohms.

AO144D

4. If not within specifications, replace the injector.

Removing

1. Loosen the clamp securing the fuel supply hose to

the fuel rail; then remove the hose from the fuel

rail.

2. Disconnect the wiring harness from each injector.

3. Remove the two screws securing the injector hold-

down plate to the throttle body assembly; then

remove the plate from the injectors.

AO145D

4. Remove the fuel injectors from the throttle body

assembly.

AO146D

! CAUTION

The fuel supply hose may be under pressure.

Place an absorbent towel around the connection

to absorb fuel; then remove the hose slowly to

release the pressure.