Snowmobile Arctic Cat (2004 year). Manual - part 46

4-19

4

5. Secure the mixing body top by tightening the

screw and lock washer making sure the mixing

body top plate is properly positioned.

6. If applicable, connect the safety switch harness to

the main wiring harness.

7. Turn the gas tank shut-off valve to the OPEN

position.

8. Adjust the carburetors (see appropriate Adjusting

Carburetors in this sub-section).

Installing Carburetors

(Standard TM-Style)

1. Prior to installing the carburetors, the carburetor

throttle valves must be checked for

synchronization.

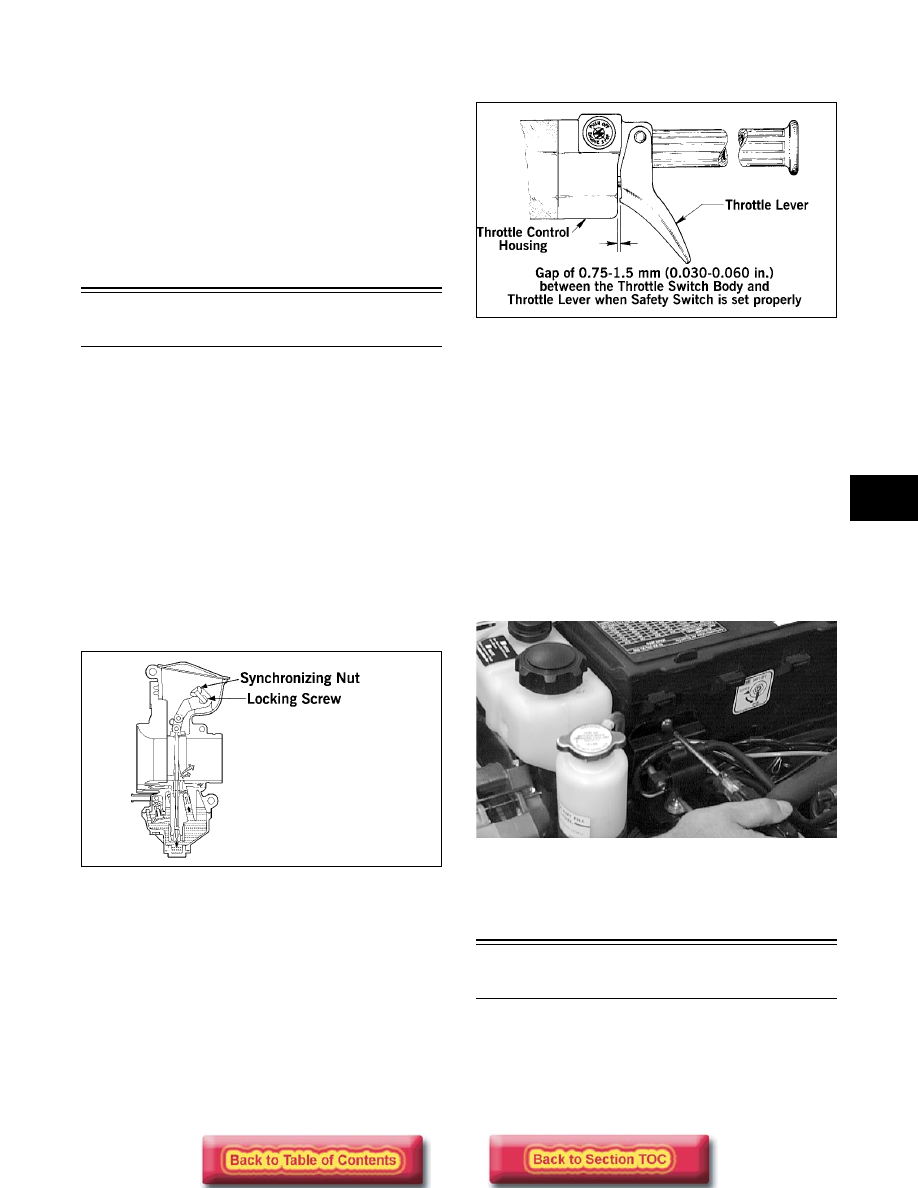

A. With the throttle in the idle position, select a

small drill bit that will just fit under the

cutaway of the fixed throttle valve.

B. Using the same drill bit, check the clearance

under the adjustable throttle valve cutaway. If

clearance is different from the first carburetor

checked, adjust the throttle valve by loosening

the lever ring locking screw; then using an

open-end wrench, rotate the synchronizing nut

in either direction until the clearance is the

same as the first carburetor checked.

0734-445

C. After synchronization has been attained, hold

the synchronizing nut with the open-end

wrench and tighten the lever ring locking

screw.

2. Place the carburetors (with float chamber vent

hoses) in the engine compartment and into the

carburetor boot; then tighten the clamps.

3. Connect the fuel supply hose to the fuel inlet T-

fitting.

4. Connect the throttle cable and choke cables.

5. At this point, there must be free-play gap in the

throttle lever.

733-081C

NOTE: If throttle cable free-play is incorrect, the

throttle safety switch will be activated prematurely

and the engine will not start.

NOTE: If cable free-play must be corrected, uti-

lize the jam nuts on the throttle cable bracket until

no free-play is attained.

6. Place the air-intake silencer into position in the

engine compartment making sure the carburetors

are properly positioned in the boot and secure with

screws.

7. Place the ignition coil/fuel pump mounting plate

into position on the air-intake silencer and secure

with the machine screw and washer.

AN613D

8. Adjust the carburetors (see appropriate Adjusting

Carburetors in this sub-section).

Installing Carburetors

(“Laydown” Engine TM-Style)

1. Prior to installing the carburetors, the carburetor

throttle valves must be checked for

synchronization.