Snowmobile Arctic Cat (2004 year). Manual - part 31

2-111

2

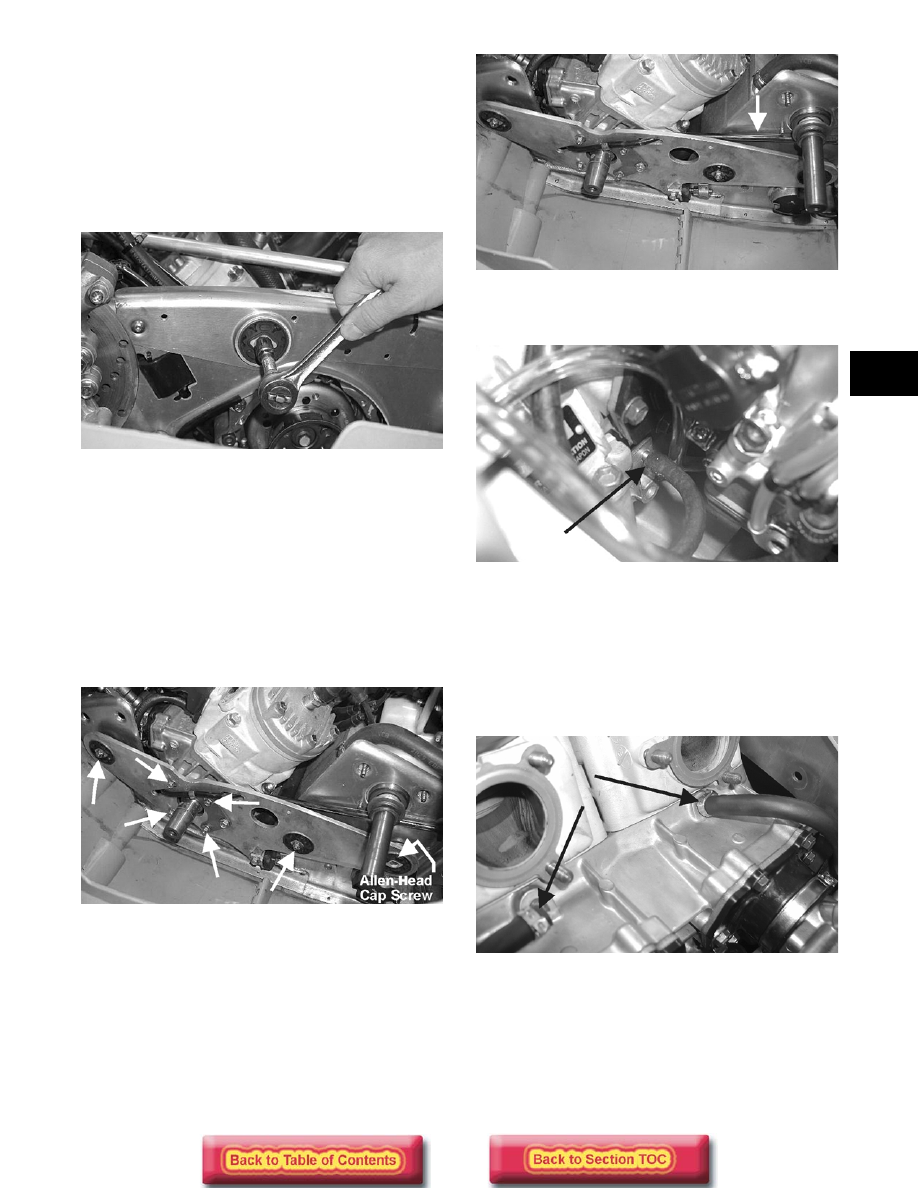

3. Connect all electrical wiring making sure all

wiring and coolant hoses are routed properly; then

place the engine into the mounting position.

NOTE: Use cable ties to secure the wiring har-

nesses as necessary.

4. Install the cap screw securing the right-side engine

mounting bracket to the side plate. DO NOT

TIGHTEN AT THIS TIME.

FC011

5. Install the left-side engine mounting bracket with

the reinforcement plate securing the mounting

bracket to the engine; then secure the mounting

bracket to the front frame. Tighten bracket

hardware to 1-1.2 kg-m (7-9 ft-lb).

6. Tighten the four mounting bracket/reinforcement

plate to engine 8 mm cap screws to 2.5-2.8 kg-m

(18-20 ft-lb); then tighten the two lock nuts and

one Allen-head cap screw with lock nut to 2.5-2.8

kg-m (18-20 ft-lb). Tighten the right-side engine

cap screw and nut to 2.5-2.8 kg-m (18-20 ft-lb).

FC010A

7. Connect the oil-injection cable/control rod to the

oil-injection pump and secure; then route the oil-

supply hose through the left-side engine mounting

bracket, into the reinforcement plate, and to the

pump and secure with the clamp. Bleed the oil-

injection system (see Section 4).

FC008A

8. On carbureted models, connect the impulse hose

to the crankcase.

FC007A

9. Confirm that the two coolant hoses which run

beneath each exhaust port on the cylinders are

accessible to connect and that the fuel line and oil

pump linkage (EFI) or cable (carbureted) and

impulse lines are connected; then place the throttle

bodies/carburetors into position and secure with

the flange clamps. Synchronize the oil-injection

pump (see Section 4).

FC050A