Snowmobile Arctic Cat (2004 year). Manual - part 25

2-87

2

MD0090

30. Install the intake flange assembly using washers,

lock washers, and nuts. Note the placement of

gaskets, heat deflector, gaskets, insulators, and

flanges. Tighten the nuts (threads coated with red

Loctite #271) to 1.8-2.2 kg-m (13-16 ft-lb).

31. Install the exhaust manifold and gaskets using lock

washers and nuts. Tighten the nuts to 1.8-2.2 kg-m

(13-16 ft-lb).

Assembling Engine

(600 cc Standard Engine Model)

NOTE: The use of new gaskets and seals is rec-

ommended when assembling the engine.

NOTE: When the use of a lubricant is indicated,

use Arctic Cat Synthetic APV 2-Cycle Oil.

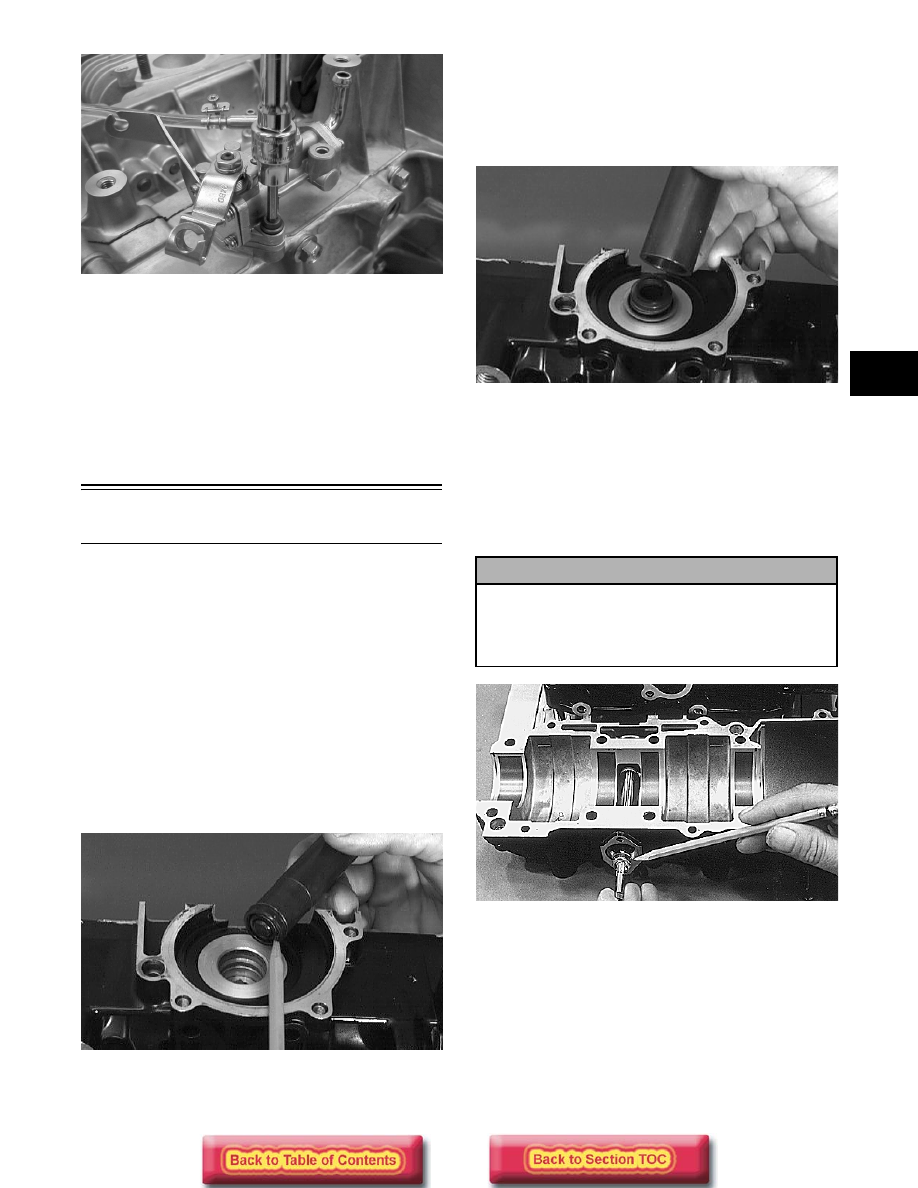

1. Apply a thin coat of grease to the inner seal lips of

the water pump seal.

2. Using the seal driver, position the inner water

pump shaft seal onto the seal driver and gently tap

the seal down into position.

NOTE: Grease must be applied to the lips of the

inner seal before installation.

AN070D

NOTE: The seal must be installed with its spring

side towards the crankshaft.

3. Install the snap ring securing the inner seal in the

crankcase.

4. Using the seal driver, carefully install the outer

water pump seal. Gently tap the seal down into

position until it seats itself against its flange.

AN072D

5. Apply a thin coat of grease to the sealing surface

of the oil-injection pump/water pump driveshaft;

then place the Oil Seal Installation Tool (p/n 0644-

219) at the end of the shaft. Twist the driveshaft

clockwise as it is pushed through the oil and water

pump seals; then remove the tool. Position the

shim on the oil-injection pump end of the

driveshaft.

AN074

6. Position the upper crankcase half upside-down on

two wooden blocks; then install the C-ring, the

four bearing retaining pins, and the two crankcase

dowel pins.

7. Place the PTO-side crankshaft bearing into

position making sure the bearing retaining pin hole

is positioned inward.

NOTE: The bearing retaining pin hole is the hole

that doesn’t go entirely through the bearing case.

! CAUTION

Be very careful not to damage the seals when

installing the oil pump driveshaft. Be certain to

use the seal installation tool. Twist the driveshaft

clockwise as it enters the seal area and while it is

being pushed through the seals.