Snowmobile Arctic Cat (2004 year). Manual - part 19

2-63

2

FC059

4. Connect the two coolant hoses on the cylinders

beneath the exhaust ports.

FC050A

5. Install the APV’s onto the cylinder and secure with

existing hardware.

FC056

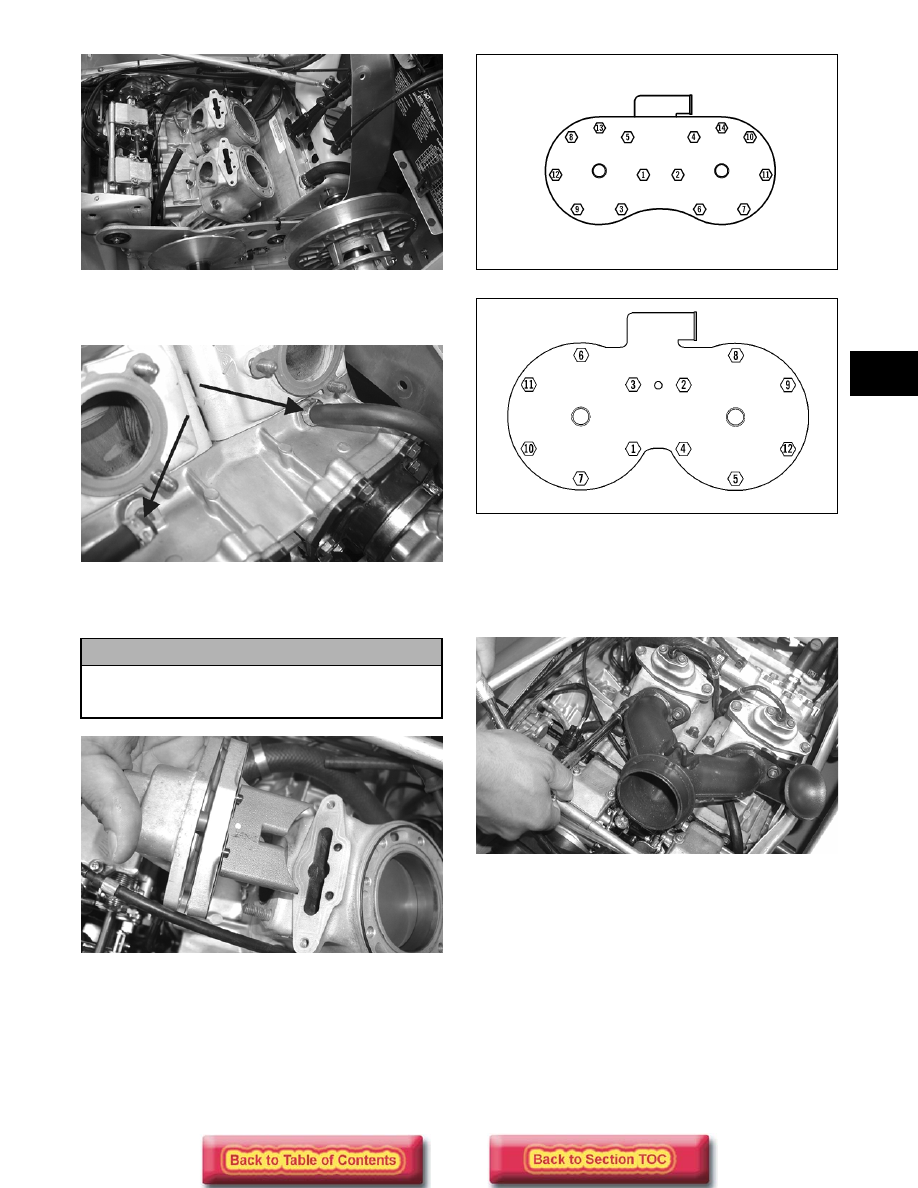

6. Place the cylinder head into position on the

cylinders making sure the O-rings are properly

positioned; then on the 500 cc in two steps, tighten

the 6 mm cap screws to 0.9-1.3 kg-m (6.5-9.5 ft-

lb) and on all models in two steps, tighten the

8 mm cap screws to 2.1-3.1 kg-m (15-22.5 ft-lb)

using the appropriate pattern shown.

0738-204

0738-205

7. Install the coolant hose and breather hose onto the

cylinder head.

8. Install the exhaust manifold. Tighten existing

hardware to 1.8-2.2 kg-m (13-16 ft-lb).

FC049

9. Install the expansion chamber and resonator using

existing hardware.

10. Install the side-plate brace and secure with

existing hardware.

11. Fill the cooling system with recommended coolant

(see Liquid Cooling System in Section 3).

! CAUTION

The long side of the exhaust valve must be

facing toward the cylinder head or severe engine

damage may occur.