Snowmobile Arctic Cat (2002 year). Manual - part 172

9-166

Servicing I.F.P.

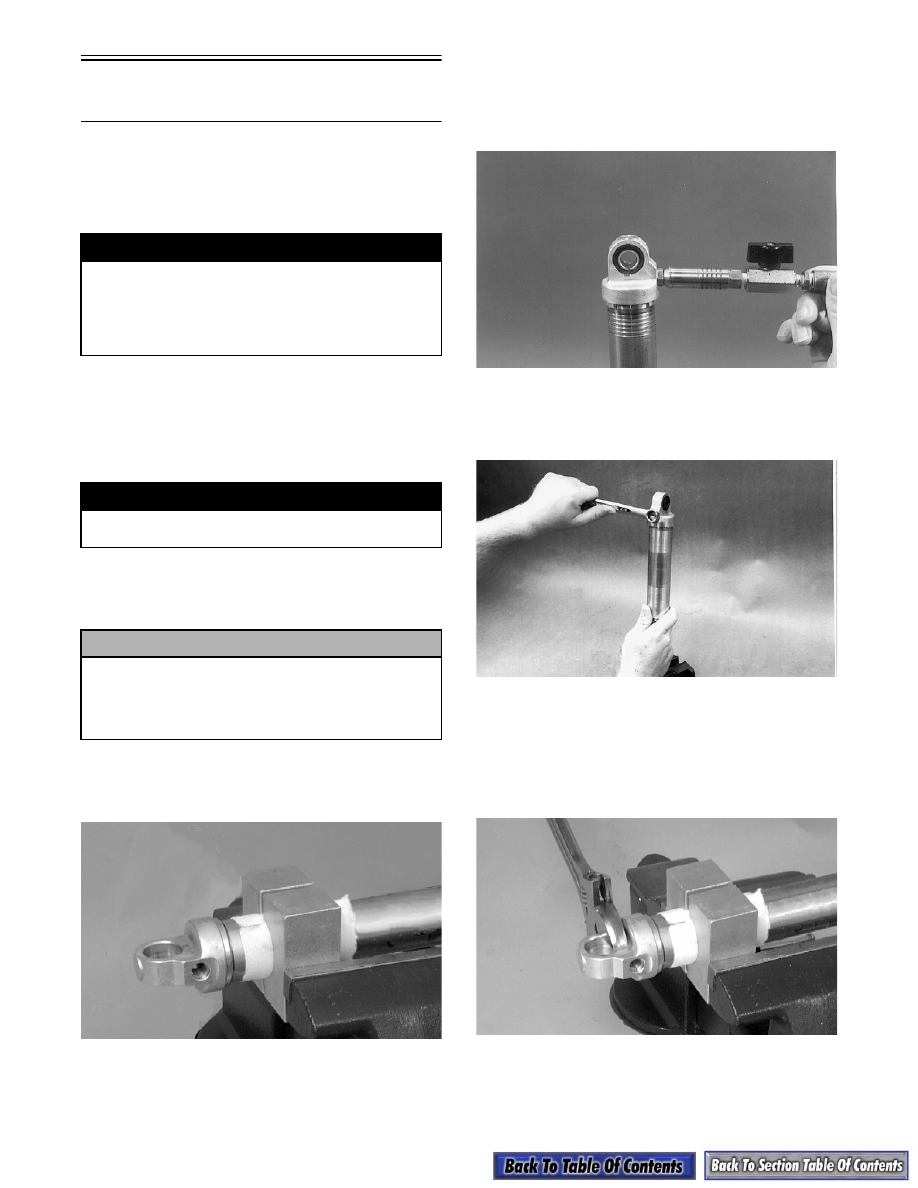

Style Shocks

NOTE: Some illustrations and photographs used

in the following sub-sections are used for clarity

purposes and are not designed to depict actual

conditions.

DISASSEMBLING

1. Remove the shock from the snowmobile.

2. Wash the shock body in parts cleaner; then dry

with compressed air to remove sand and dirt.

3. Place the shock into the Gas Shock Retaining

Blocks (p/n 0644-142); then remove shock eyelet

mounting axle and bushings from end cap.

NOTE: A paper shop towel between the shock

body and retaining blocks will help prevent scuff-

ing of the shock body.

AP110DA

4. Remove the screw from the bladder housing on the

bottom of the shock. Discharge all the pressure

from the shock using the Shock Inflation Needle

(p/n 0644-158). Open the valve in filler handle

until all pressure is released.

AG335

5. Using a 9/16-in. wrench, remove the brass bladder

housing from the lower end cap. Account for an

O-ring.

AP014

6. Using a large adjustable wrench (12-in. or 14-in.),

remove the end cap.

NOTE: 1994 and older shocks have Loctite on

the lower end cap. Heating the lower end cap may

be necessary. Use care not to overheat.

AP016DA

7. Using a 1-in. open end wrench, loosen the shock

shaft bearing cap a couple of turns.

! WARNING

Before servicing a gas shock absorber, first dis-

charge all pressure from the shock. Remove the

screw from the bottom of the shock and insert the

Shock Inflation Needle (p/n 0644-158). Open valve

until all pressure is released. Failure to do this may

cause personal injury.

! WARNING

When using compressed air to dry components,

always wear safety glasses.

! CAUTION

It is important that the Gas Shock Retaining

Blocks (p/n 0644-142) are used during both

disassembly and assembly. Any other method of

securing the shock body during these

procedures may deform the shock body cylinder.