Snowmobile Arctic Cat (2002 year). Manual - part 112

8-6

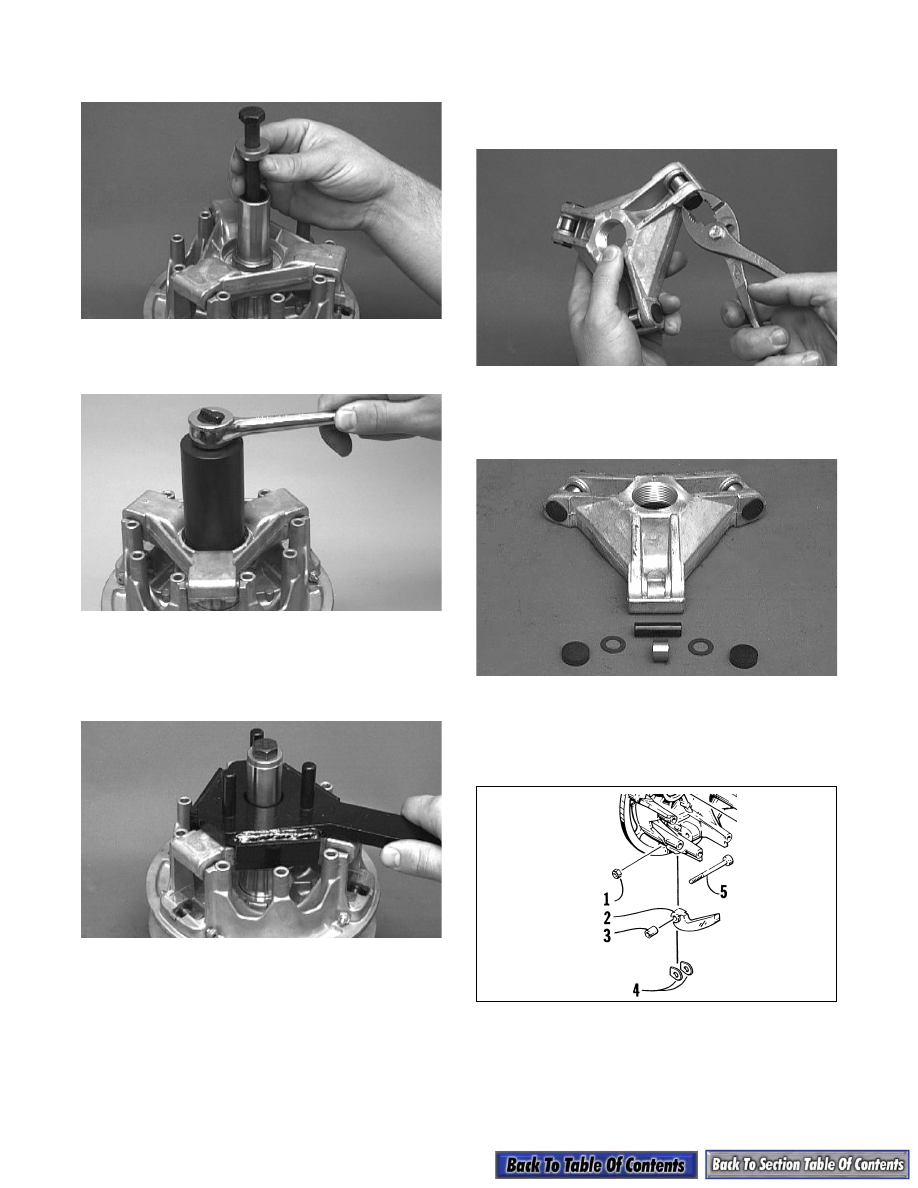

4. Secure the drive clutch to the holder using the

clutch bolt and lock washer.

AM064D

5. Using the Thin Wall Deep Socket (p/n 0644-138),

remove the spider retainer nut.

AM065D

6. Using a small torch, heat the threaded area of the

spider. Place the Spider Removal Tool (p/n 0644-

085) over the heated spider and break spider loose

by turning it counterclockwise.

AM067D

NOTE: Applying heat to the spider threaded area

will aid in clutch disassembly. The heat will loosen

the Loctite used during assembly.

7. Remove the drive clutch from the clutch holder

using the clutch puller and the same procedure as

pulling the drive clutch from the crankshaft.

8. Remove the spider, spacer washers, and movable

sheave.

9. Using a pair of pliers, remove the six spider

buttons.

AM070D

10. Using a punch, push each pin from the roller.

Account for the roller washers (one on each side of

each roller).

AM071D

11. Remove the three cam arm pins and lock nuts

securing the cam arms to the movable sheave; then

remove each cam arm and account for the

bushings and the washers.

733-452B

KEY

1. Lock Nut

2. Cam Arm

3. Bushing

4. Washer

5. Pin