Snowmobile Yamaha FX10X, FX10RTX, FX10RTRX, FX10RTRAX, FX10MTX, FX10MTRX, FX10MTRAX. Manual - part 52

5-28

ENG

INSTALLATION

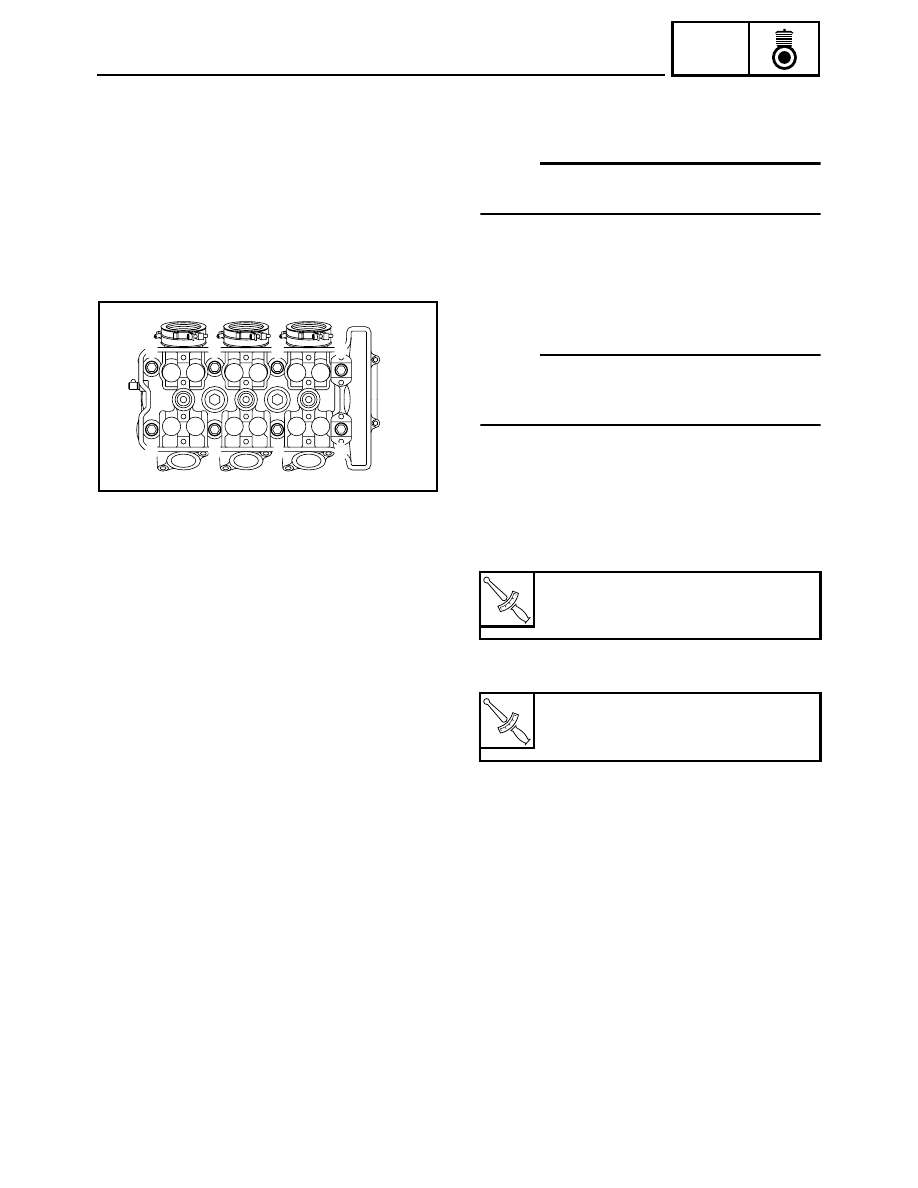

1. Install:

• Cylinder head

NOTE:

Pass the timing chain through the timing chain cav-

ity.

2. Tighten:

• Cylinder head bolts (M10)

NOTE:

The tightening procedure of the cylinder head bolts

is angle controlled, therefore tighten the bolts using

the following procedure.

Tightening steps:

• Lubricate the cylinder head bolts and washers

with engine oil.

• Install the washers and cylinder head bolts.

• Tighten the cylinder head bolts in the proper

tightening sequence as shown.

• Loosen and retighten the cylinder head bolts in

the proper tightening sequence as shown.

T

R

.

.

Cylinder head bolt (M10):

1st:

25 Nm (2.5 m · kg, 18 ft · lb)

T

R

.

.

Cylinder head bolt (M10):

2nd:

25 Nm (2.5 m · kg, 18 ft · lb)

6

7

3

1

5

2

4

8