Snowmobile Yamaha FX10X, FX10RTX, FX10RTRX, FX10RTRAX, FX10MTX, FX10MTRX, FX10MTRAX. Manual - part 29

4-5

POWR

TR

PRIMARY SHEAVE AND DRIVE V-BELT

2. Inspect:

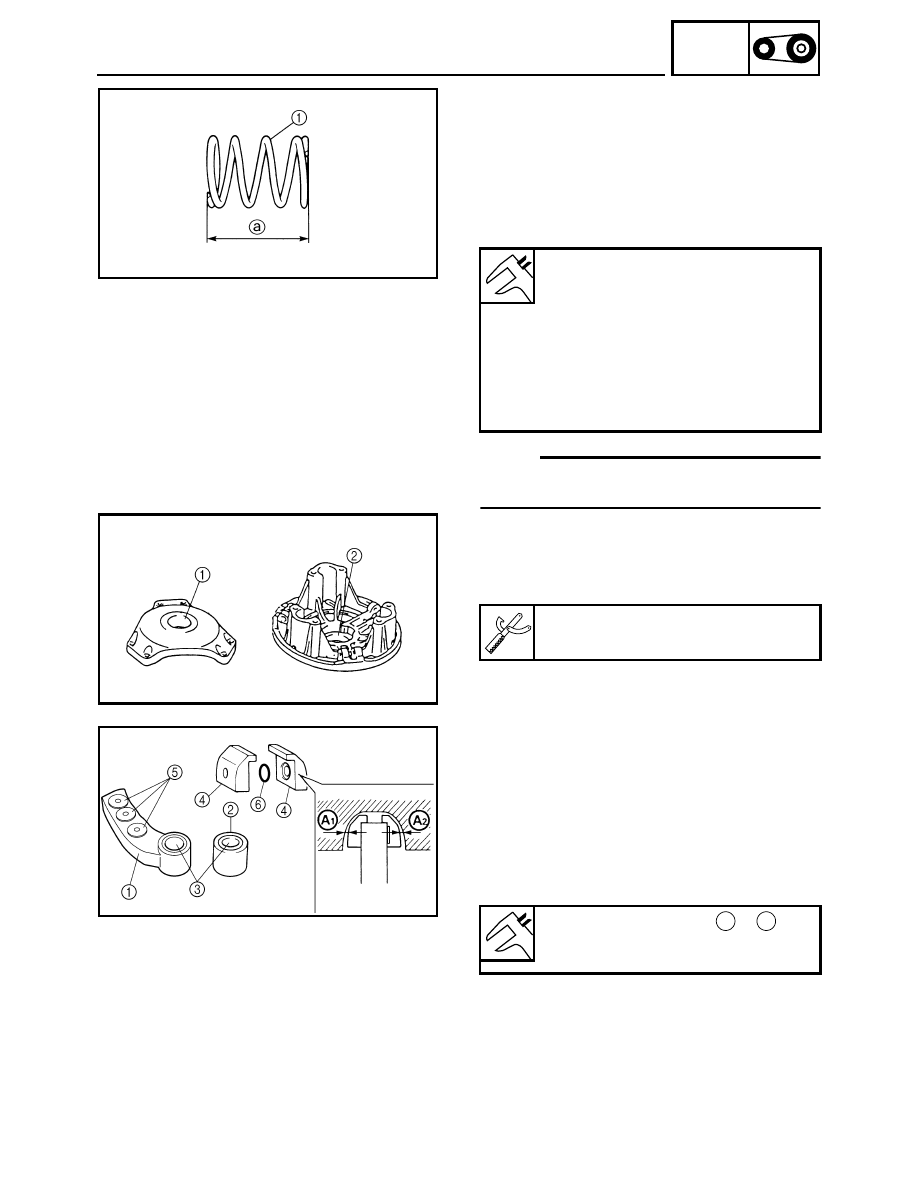

• Primary sheave spring 1

Cracks/damage

→ Replace.

3. Measure:

• Primary sheave spring (standard) free length

a

Out of specification

→ Replace the primary

sheave spring.

NOTE:

When changing the primary sheave springs, refer

to “GEAR SELECTION” in CHAPTER 2.

4. Inspect:

• Primary sheave cap bush 1

• Sliding sheave bush 2

Cracks/damage

→ Replace.

Primary sheave spring (standard)

free length:

FX10/FX10RT/FX10RTR/FX10RTRA

87.4 mm (3.44 in)

FX10MT “USA/Canada”/FX10MTR

“USA/Canada”

89.8 mm (3.54 in)

FX10MTR “Europe”/FX10MTRA

“Europe”

98.4 mm (3.87 in)

Clutch bushing press:

90890-01529, YS-42424

5. Inspect:

• Weight 1

• Roller 2

• Bushing 3

• Slider 4

• Rivet 5

• O-ring 6

• Collar

Wear/scratches/damage

→ Replace.

Slider inside clearance

+

:

Min. 0 mm (0 in)

Max. 0.3 mm (0.0118 in)

A

1

A

2