Snowmobile Polaris IQ (2007-2008 year). Manual - part 66

9.16

Shocks

pressure in 5 PSI increments until the desired

performance level is achieved.

Again, always reset the shock body chamber pressure to

the factory specification charge.

If one shock appears to be too soft, place the vehicle on

flat, level ground. Stand on the sled, and rock the skis back

and forth to verify issue.

Determine if the shock is leaking or has leaked an oil, then

determine why. Look for shaft damage and replace the

shaft and seal if damage is found.

If no oil leaks are found, verify there are no gas leaks at the

charge ports. Replace the charge ports as required.

After inspecting both shocks, recharge both shocks to the

desired pressure settings and specifications.

SHOCK MAINTENANCE

Ryde FX Air 2.0 Shock Disassembly

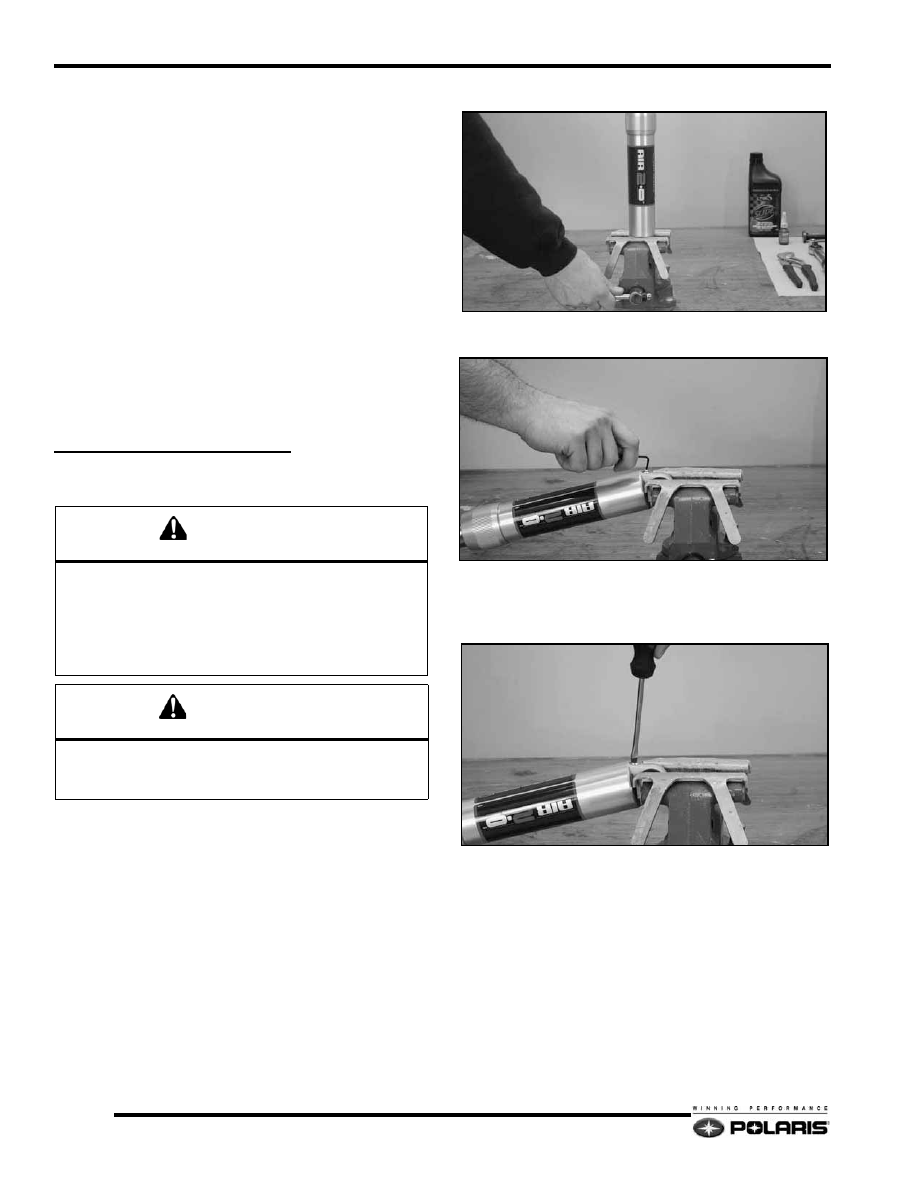

1.

Remove the shock from the snowmobile. Wash the entire

shock assembly in parts cleaner, then dry with compressed

air or a clean shop towel.

2.

Remove lower shock body mount eyelet components.

Secure shock in a soft-jawed table vise.

3.

Remove both small bottom head screws form each pressure

valve assemblies located at both ends of the shock.

4.

Using a flat-blade screwdriver, carefully loosen both

pressure valve assemblies counter-clockwise two full

rotations. Allow all of the nitrogen gas to fully escape past

each pressure valve assembly o-ring.

WARNING

Before servicing a gas shock it is important that all the

gas pressure be discharged from the shock.

Nitrogen gas is under extreme pressure. Protective

eyewear must be worn at all times to avoid risk of injury

while servicing shocks or using compressed air.

CAUTION

Always clamp the lower mount of the shock in a vise. Any

other method of securing the shock body may deform

the shock body cylinder.