Snowmobile Polaris IQ (2007-2008 year). Manual - part 34

5.14

Engine and Cooling Systems

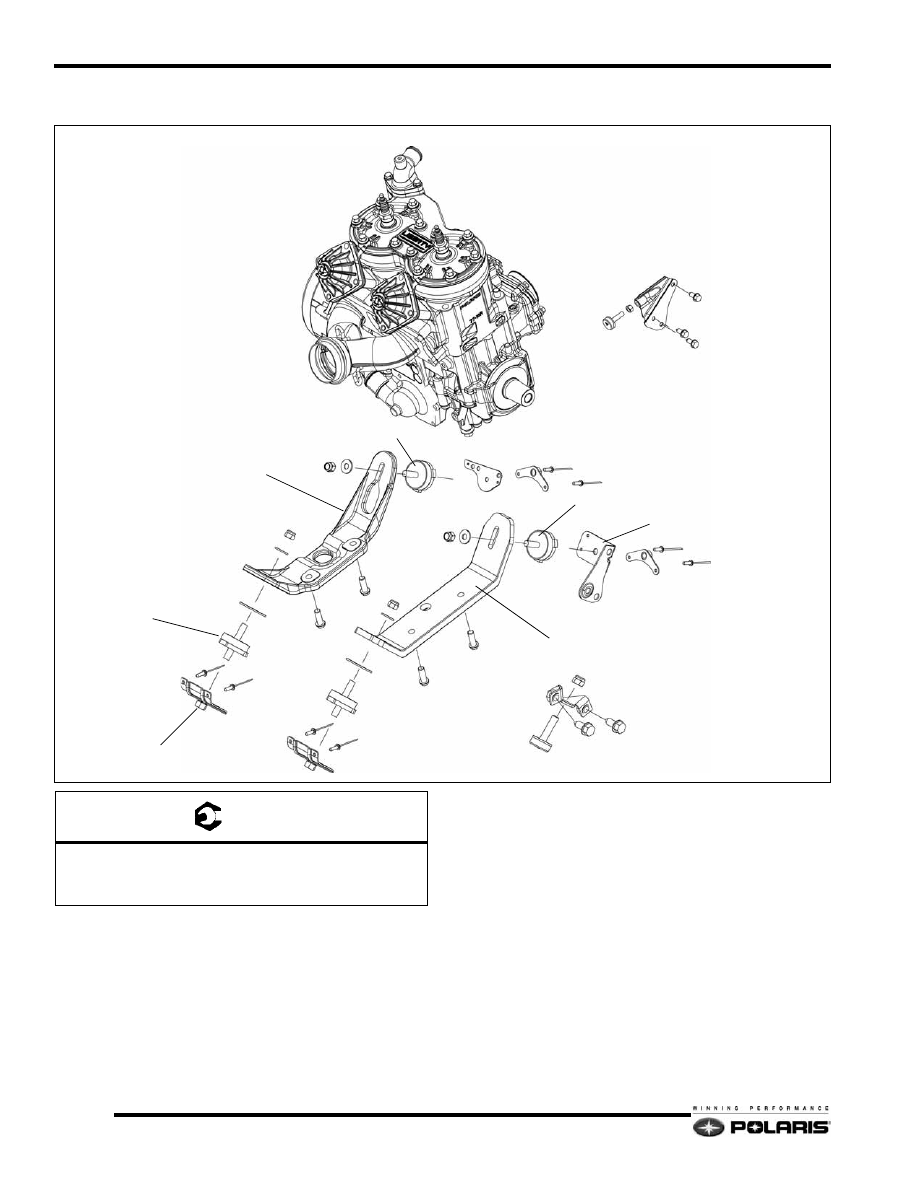

2007 IQ 600 CFI Engine Mounting

NOTE: Use an engine mount socket, PN: 2871989 to

remove the engine mounts from the bulkhead.

ISOLATOR

TORQUE STOP

ENGINE ASSEMBLY

CLINCH PLATE

ENGINE MOUNT

ENGINE MOUNT

ENGINE MOUNT

RH ENGINE STRAP

LH ENGINE STRAP

ENGINE MOUNT BRACKET

A

A

A

A

A

A

A

A

B

C

C

C

C

= T

A = 28 Ft.Lbs. (38 Nm)

B = 15 Ft.Lbs. (20 Nm)

C = 30 Ft.Lbs. (41 Nm)