Snowmobile Polaris IQ (2007-2008 year). Manual - part 27

4.26

Fuel Systems

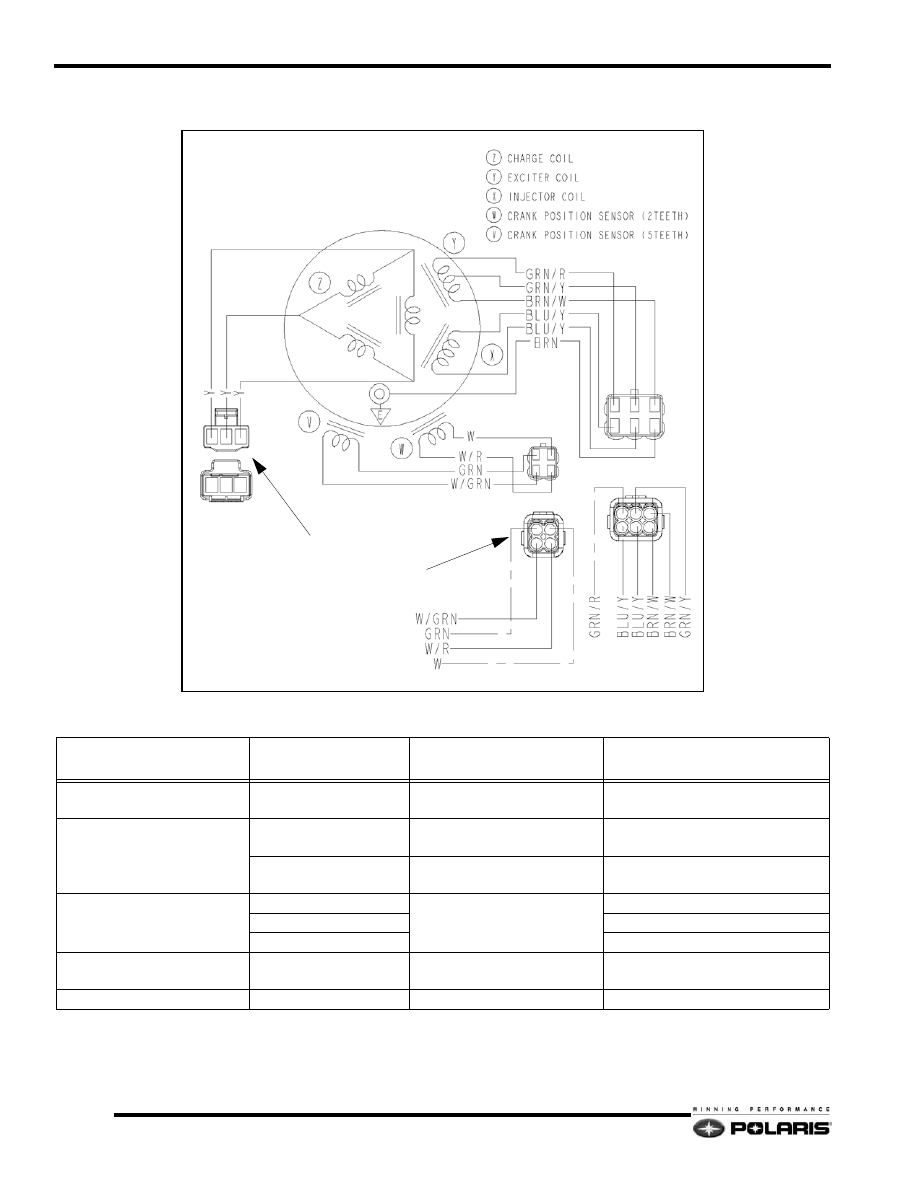

Stator Assembly

Stator Specifications

ITEM

COLOR

SYSTEM FUNCTION

RESISTANCE

+/- 15% @68

°

F (20

°

C)

CHARGE / LIGHTING COIL

YELLOW

CHASSIS / BATTERY

POWER

YEL TO YEL = 0.13

Ω

NO CONTINUITY TO GROUND

CRANK POSITION SENSOR

(CPS)

GRN to WHT/GRN

Crank Position Sensor (5

Tooth) Ignition timing.

GRN to WHT/GRN = 190

Ω

WHT to WHT/RED

Crank Position Sensor (2

Tooth) Locates TDC and RPM.

WHT to WHT/RED = 190

Ω

COILS

GRN/RED

Exciter Coil - Powers the

Ignition Coils / ECU

GRN/RED to GRN/YEL = 15

Ω

GRN/YEL

GRN/RED to BRN/WHT = 30

Ω

BRN/WHT

BRN/WHT to Ground = 0

Ω

INJECTOR POWER COIL

BLU/YEL TO BLU/YEL

Supplies power to fuel

injectors.

BLU/YEL to BLU/YEL = 2.4

Ω

ENGINE GROUND

BROWN

ENGINE GROUND

0

Ω

CRANK POSITION

SENSORS

REG REC