Snowmobile Polaris Two Stroke (2007 year). Manual - part 45

7.7

FINAL DRIVE/BRAKES

7

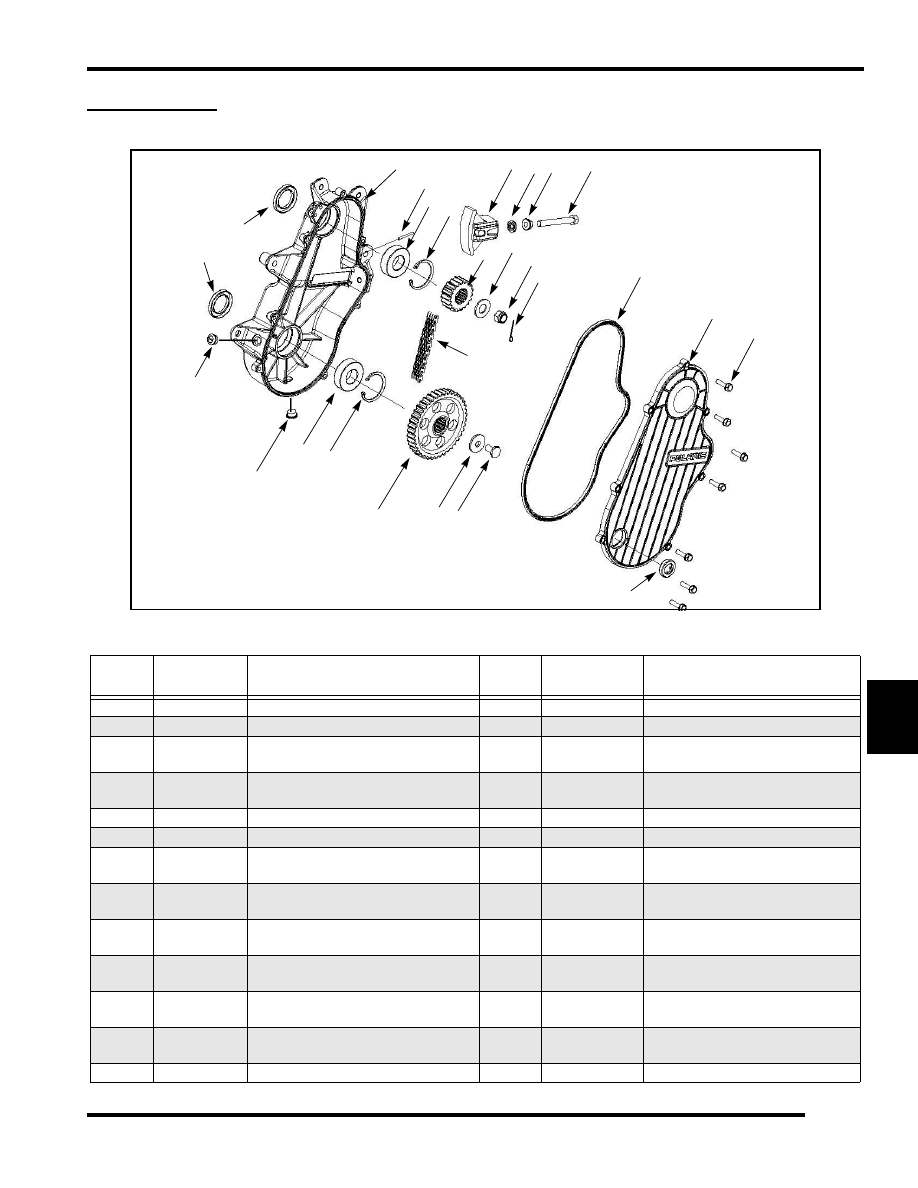

CHAIN CASE

Exploded View

Chaincase

ITEM

DESCRIPTIO

N

TORQUE SPECIFICATION / NOTES

ITEM

DESCRIPTION

TORQUE SPECIFICATION /

NOTES

A

Cover bolts

8 ft-lb(11N-m) N

Breather

roll

pin

B

Chaincase cover

O

Chaincase

C

Cover gasket

make sure that the gasket is not pinched

during assembly

P

Upper seal

Install so that the lip is facing the

chaincase

D

Cotter pin

bend the ends over the nut flats when

installing

Q

Lower seal

Install so that the lip is facing the

chaincase

E

Jackshaft nut

50 ft-lb (62.5N-m)

R

Fill plug

F

Washer

S

Drain plug

8 ft-lb (11N-m)

G

Top sprocket

Install so that the shoulder is facing the

bearing

T

Lower bearing

Loctite 680 when assembled

H

Chain tensioner

adjuster

Torque only finger tight during assembly

U

Lower c-clip

Install so that the chamfered edge is

facing the bearing

I

Tensioner lock

nut

V

Chain

J

Fastener Seal

Thread this onto the adjuster bolt during

assembly

W

Lower sprocket

Install so that the shoulder is facing the

bearing

K

Tensioner

Assembly

X

Washer

L

Upper c-clip

Install so that the chamfered edge is facing

the bearing

Y

Lower sprocket

retaining bolt

19 ft-lb (26N-m)

M

Upper bearing

Loctite 680 when assembled

Z

Sight glass

Only remove if replacing

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

R

S

T

U

V

W

X Y

Z

image depicts 8.373 chaincase, your chaincase may vary slightly