Snowmobile Polaris EDGE / WIDETRAK (2007-2012 year). Manual - part 33

5.30

Engine Systems

9923396 - 2007-2012 EDGE/Widetrak LX Service Manual

©2011 Polaris Sales Inc.

488 LIQUID-COOLED ENGINE

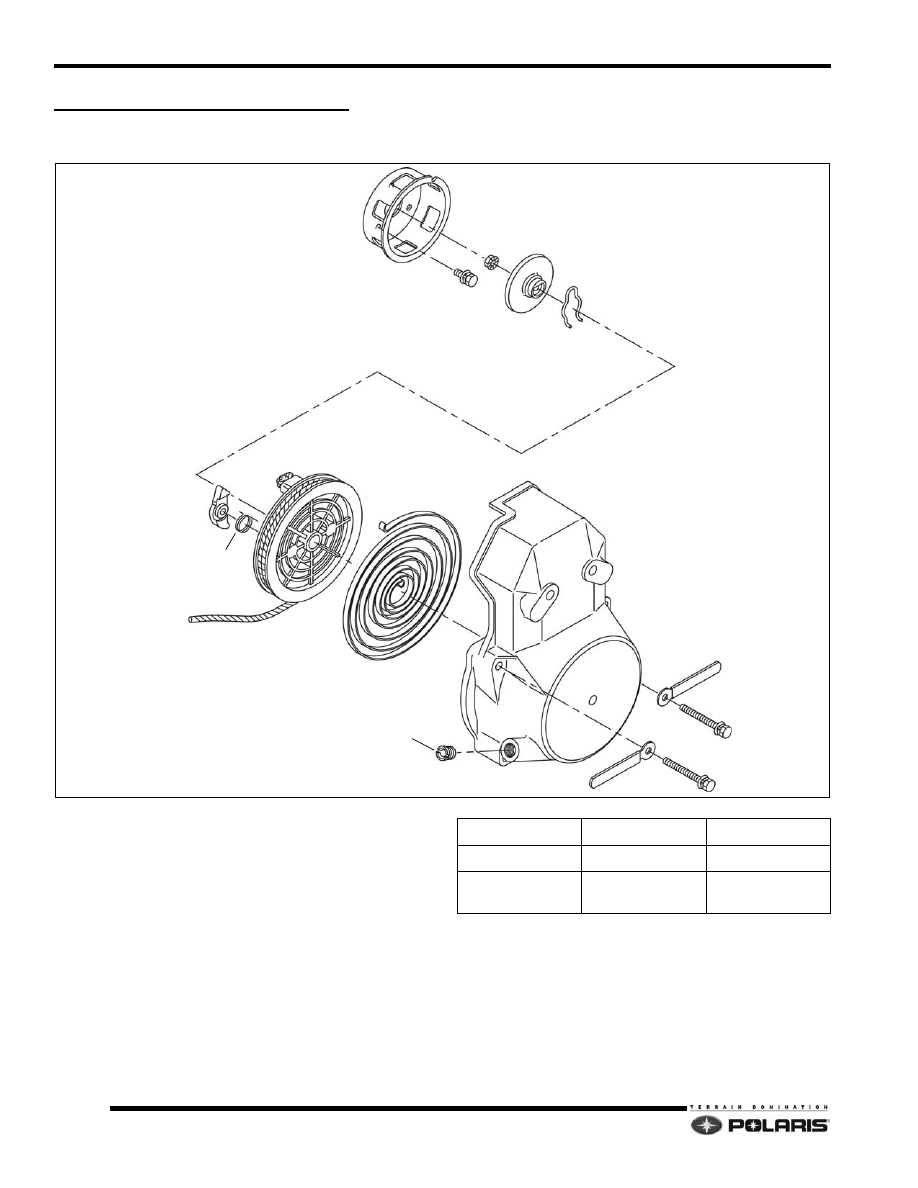

Recoil / Water Pump Housing Assembly

Disassembly / Assembly Process

1.

Clamp recoil rope with a pliers at the engine. Remove

recoil handle from rope, pull the rope through the

console, then tie a knot just above the pliers. Remove

the pliers.

2.

Remove fasteners securing recoil / waterpump

housing to engine. The recoil pulley mechanism is

located inside the housing.

3.

Reference RECOIL PULLEY section for recoil

disassembly / assembly information.

4.

Lock the ratchet hub with a large screwdriver and

remove the fasteners that secure the hub and

waterpump pulley to the flywheel.

RATCHET HUB

FRICTION PLATE

FRICTION SPRING

RATCHET

RATCHET SPRING

RECOIL PULLEY

RECOIL SPRING

RECOIL / WATERPUMP HOUSING

ROPE GUIDE

Fastener

Torque

Note

Recoil Hub

9 ft.lbs. (12 Nm)

Friction Plate /

Recoil Pulley

5 ft.lbs. (7 Nm)