Snowmobile Polaris (2006 year). Manual - part 21

3.20

MAINTENANCE

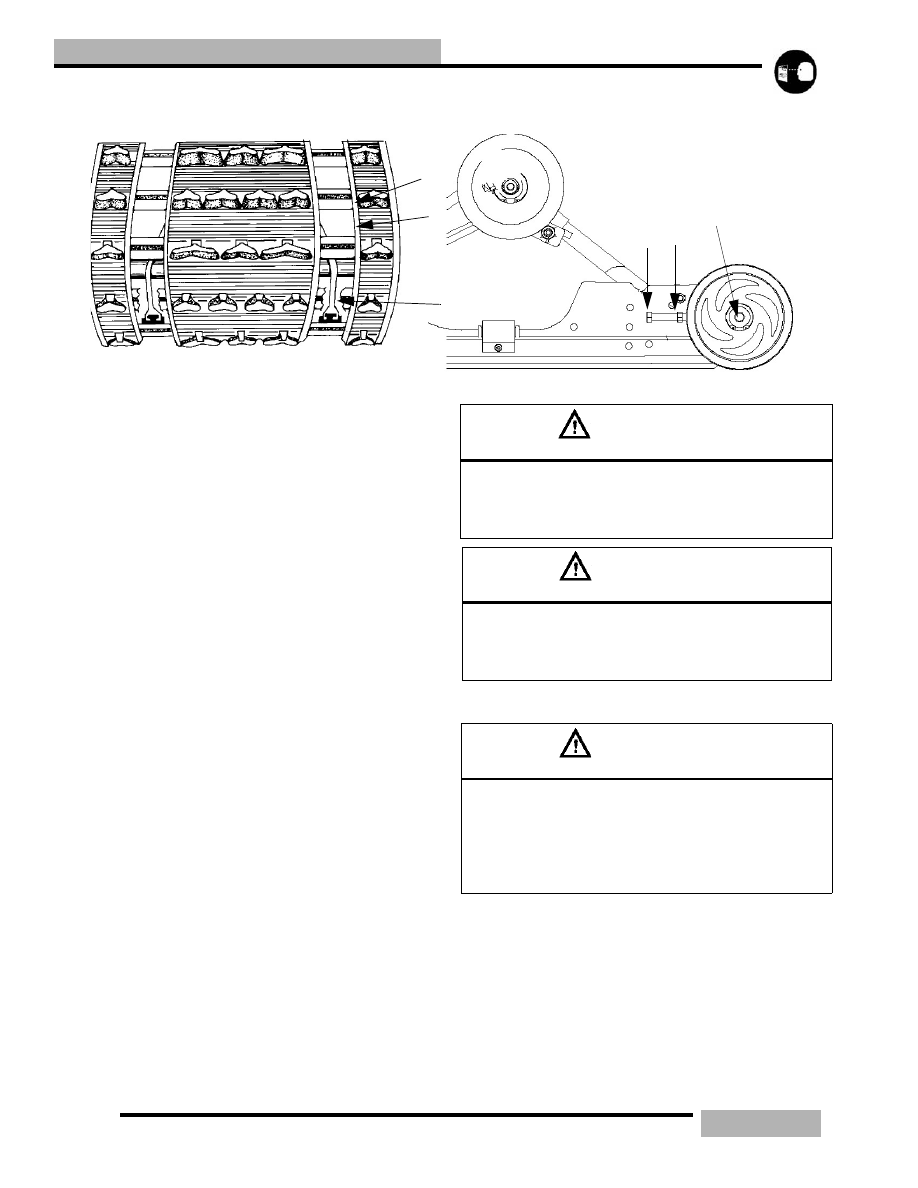

TRACK ALIGNMENT

NOTE: Track alignment affects track tension.

Misalignment of the track will cause excessive wear

to the track, rail slides, and rail.

NOTE: Excessive rail slide wear occurs due to

running in inadequate snow conditions.

Periodically check that the track is centered and running

evenly on the slide rails. Misalignment will cause excessive

wear to the track and slide rails.

1.

Safely lift and support the rear of the snowmobile off the

ground.

2.

Rotate the track by hand to check for any possible damage.

3.

Inspect the track rods (A) carefully and examine the track

along the entire length of each rod, bending the track edge

and inspecting it for breakage. If any rod damage is found,

the track should be replaced.

4.

Warm up the track by starting the engine and apply a small

amount of throttle so the track runs slowly at least five

complete revolutions.

5.

Stop the engine and turn the ignition off.

6.

Inspect track alignment by carefully looking through the

track window (B) to make sure the rails (C) are evenly

spaced on each side.

7.

Before any adjustments are made loosen up the rear idler

shaft (F).

8.

If the track runs to the left, loosen the left locknut and

tighten the left adjusting bolt (D). If the track runs to the

right, loosen the right locknut and tighten the right

adjusting bolt. It may be necessary to check this with the

engine rotating the track. Be sure to SHUT THE

MACNINE OFF before making any further adjustments.

9.

After any adjustments are complete, be sure to torque the

locknuts (E) to 35 ft-lb (48Nm).

10. Torque both idler shaft bolts (F) to 35 ft-lb (48Nm).

TRACK LUBRICATION

The slide rail needs snow for lubrication and cooling.

Excessive wear indicates insufficient lubrication. A new rail

slide can cause faster heat build-up in limited lubrication,

resulting in excessive wear.

NOTE: If excessive rail slide wear occurs due to

poor snow conditions additional wheel kits can be

added.

A

B

C

D

E

F

WARNING

Broken track rods can cause a rotating track to come off

the machine. Never operate or rotate a damaged track

under power with a broken rod. Serious injury or death

may occur.

WARNING

When performing the following checks and adjust-

ments, stay clear of all moving parts to avoid personal

injury. Never make any adjustments with the engine

running, as serious personal injury can result.

WARNING

Operating with insufficient lubrication between the rail

slide and track guide clips can cause track failure, loss

of vehicle control and loss of braking ability, which can

result in serious injury or death. Avoid operating vehicle

on ice and other surfaces that have little or no snow

conditions.