Challenger Terra Gator 3244 Chassis. Manual - part 4

627333-A

1-13

Safety

STAY CLEAR OF ROTATING DRIVE

LINES AND MOVING PARTS

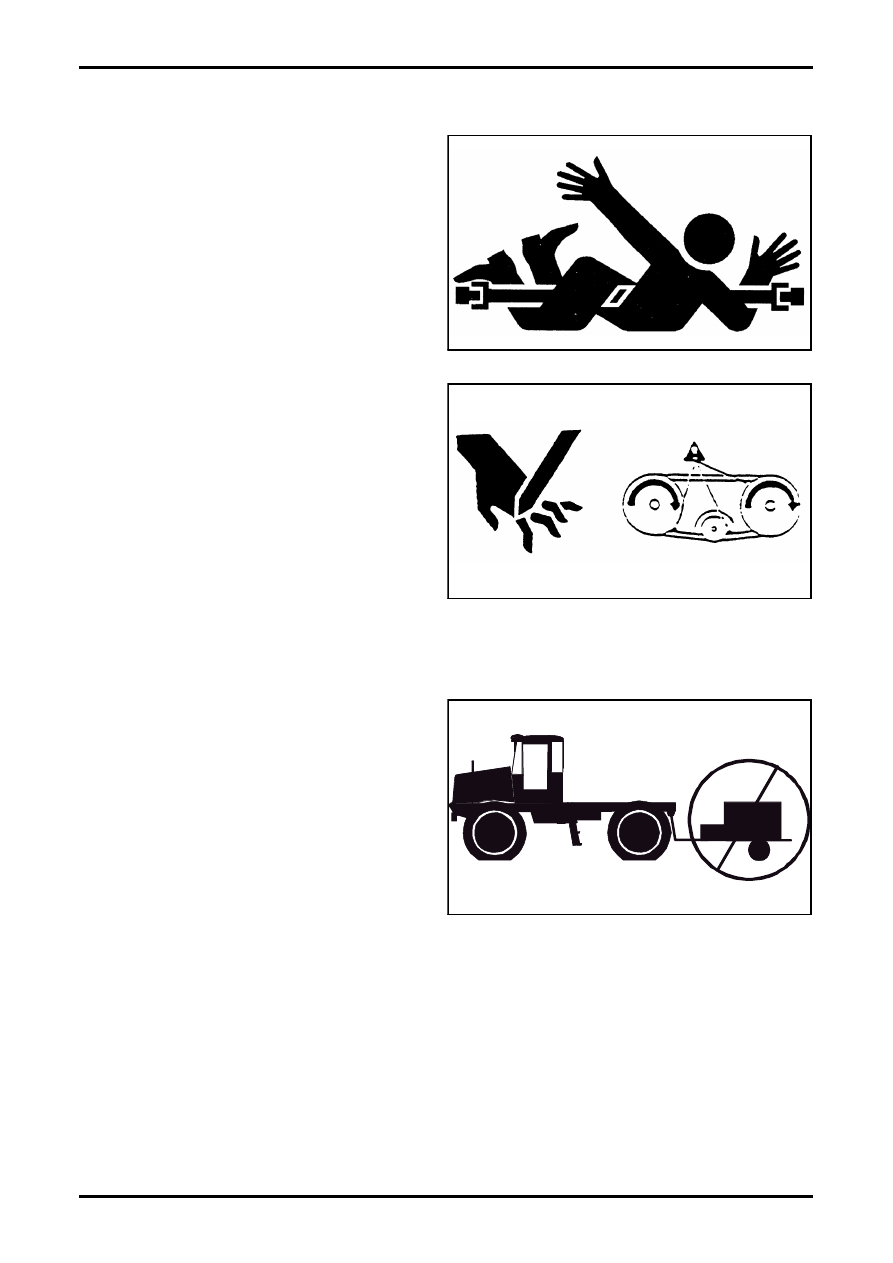

FIG. 16: Entanglement in rotating drive lines or moving

components will cause serious injury or death.

FIG. 17: Keep all safety guards and shields in place at

all times when operating the vehicle.

Turn the key switch to the OFF position. Remove the

key from the switch to prevent unauthorized operation

of the vehicle before removing any safety guards and

shields.

Wear close fitting clothing. Stop the engine and make

sure the drive lines are stopped before making any

adjustments or performing any type of service on the

engine or vehicle.

TOWING OTHER VEHICLES / TRAILERS

/ EQUIPMENT

FIG. 18: Towing of other vehicles without brakes is

NOT approved by Challenger.

Using the vehicle for towing can create a safety hazard

and can void the vehicle or system warranty.

MODIFICATIONS

Welding or altering the chassis in any way (such as

adding implement towing hitches) can cause damage

or failure of components and create a safety hazard.

Modifications not approved by Challenger can also void

the vehicle or system warranty.

FIG. 16

FIG. 17

FIG. 18