Suzuki GSX-R1000. Service Manual - part 34

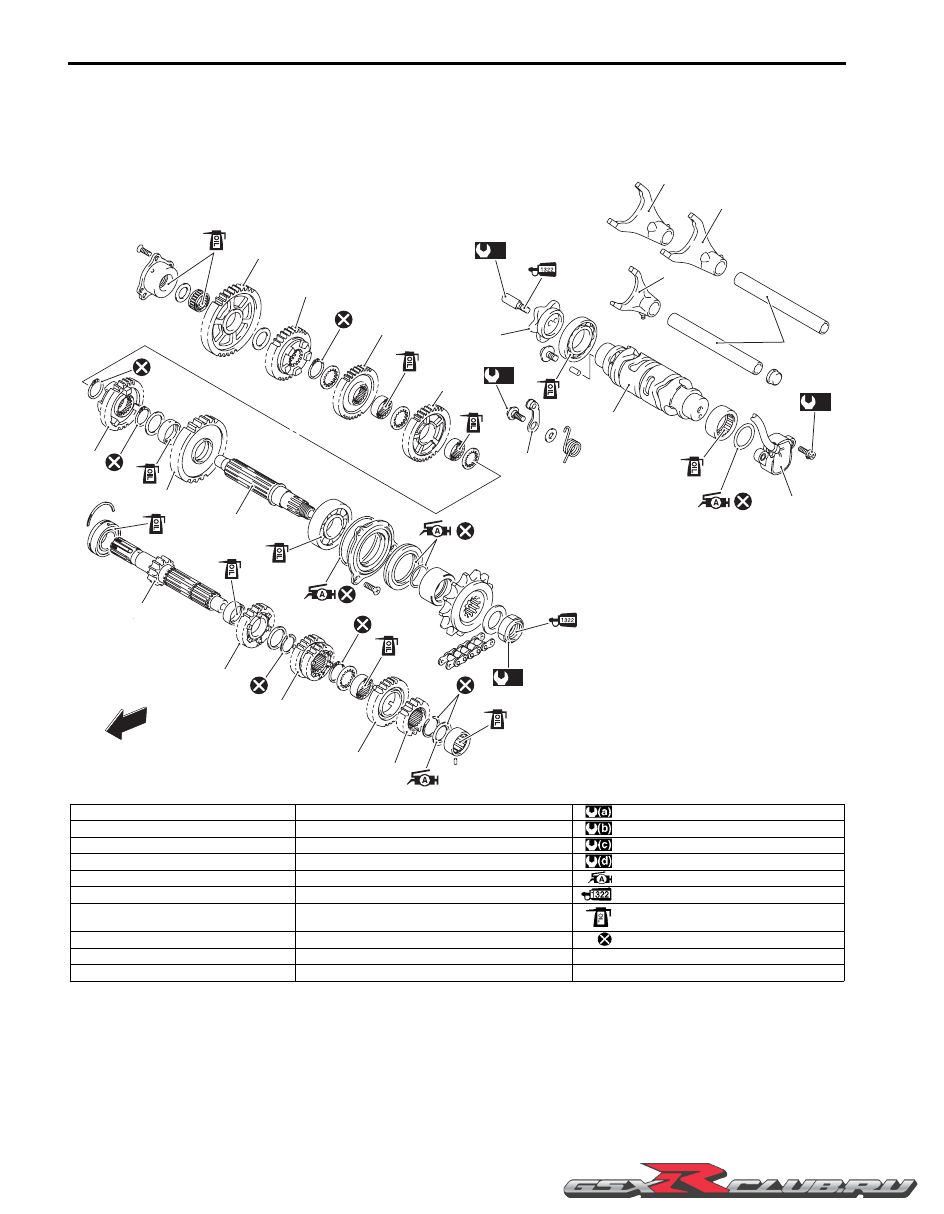

5B-2 Manual Transmission:

Repair Instructions

Transmission Components

B947H15206001

1

2

3

5

6

7

8

9

11

10

20

12

13

14

15

16

17

18

19

4

FWD

FWD

(a)

(b)

(c)

(d)

I947H1520072-02

1. 2nd drive gear

11. 5th driven gear

: 145 N

⋅

m (14.5 kgf-m, 105.0 lbf-ft)

2. 6th drive gear

12. 1st driven gear

: 10 N

⋅

m (1.0 kgf-m, 7.0 lbf-ft)

3. 3rd/4th drive gear

13. Gearshift cam stopper

: 13 N

⋅

m (1.3 kgf-m, 9.5 lbf-ft)

4. 5th drive gear

14. Gearshift cam plate

: 6.5 N

⋅

m (0.65 kgf-m, 4.7 lbf-ft)

5. Countershaft/1st drive gear

15. Gearshift cam

: Apply grease to the oil seal lip.

6. Driveshaft

16. Gearshift fork shaft

: Apply thread lock to the thread part.

7. 2nd driven gear

17. Gearshift fork (For 3rd/4th drive gear)

: Apply engine oil.

8. 6th driven gear

18. Gearshift fork (For 6th driven gear)

: Do not reuse.

9. 3rd driven gear

19. Gearshift fork (For 5th driven gear)

10. 4th driven gear

20. GP switch